Production

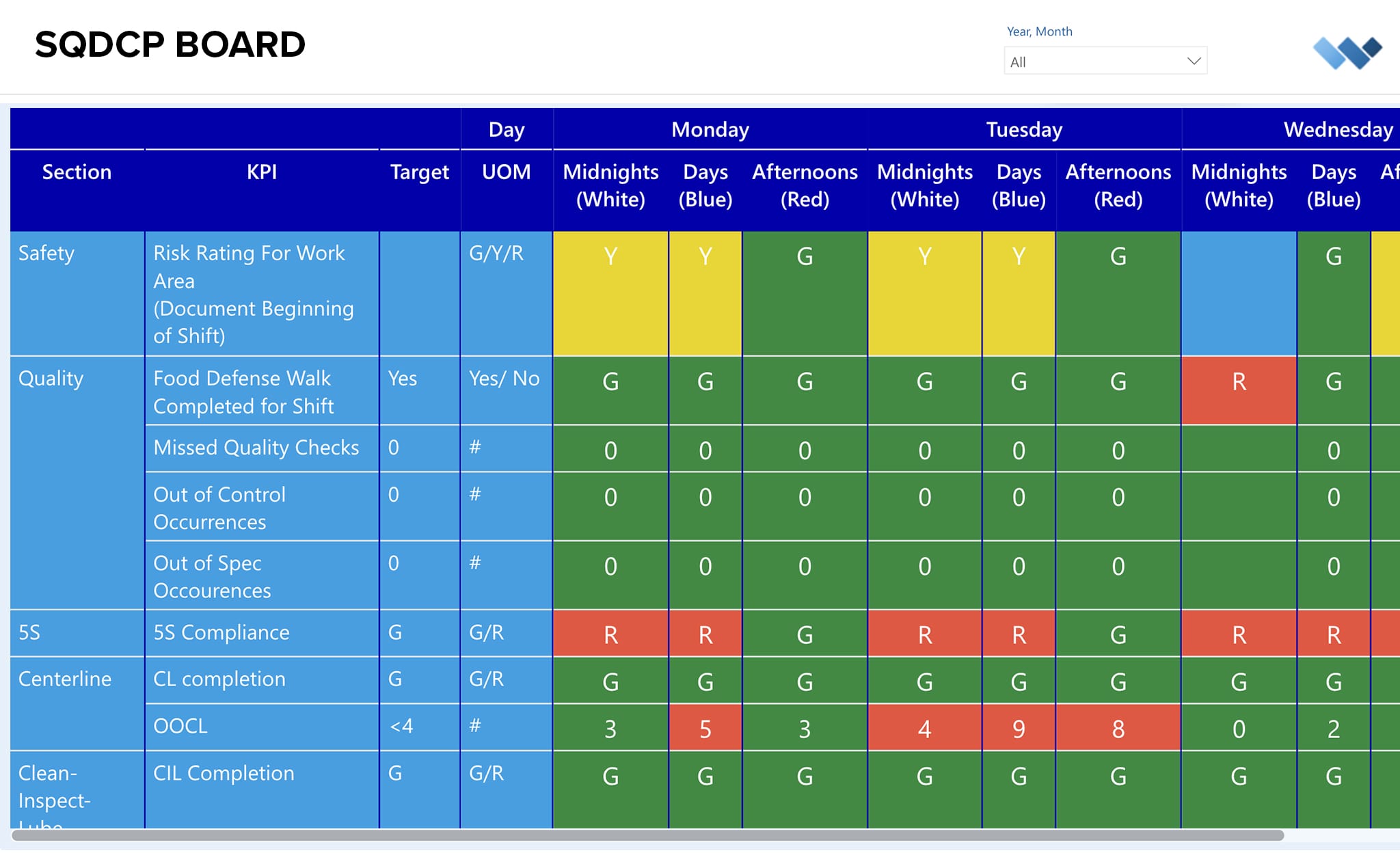

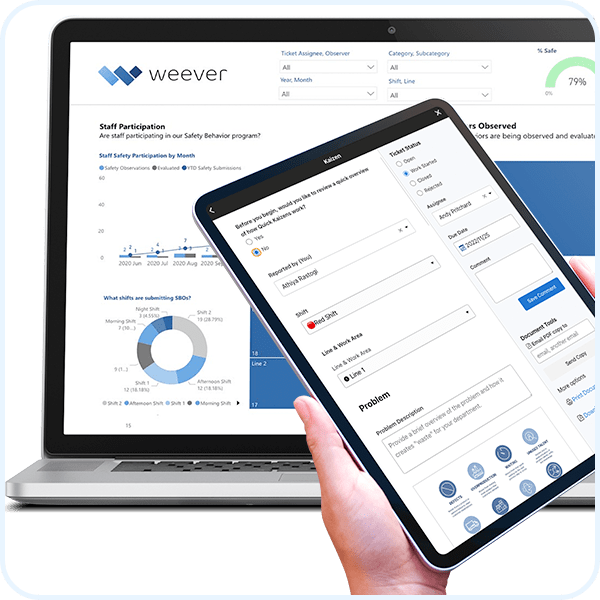

SQDCP Board

Digitize SQDCP (Safety, Quality, Delivery, Cost, and People) Boards and Supercharge Performance

Read More5S Workstation Optimization

Ensure workstations are optimized correctly and improvements are sustained by documenting Sort, Set in Order and Shine steps including photos and videos.

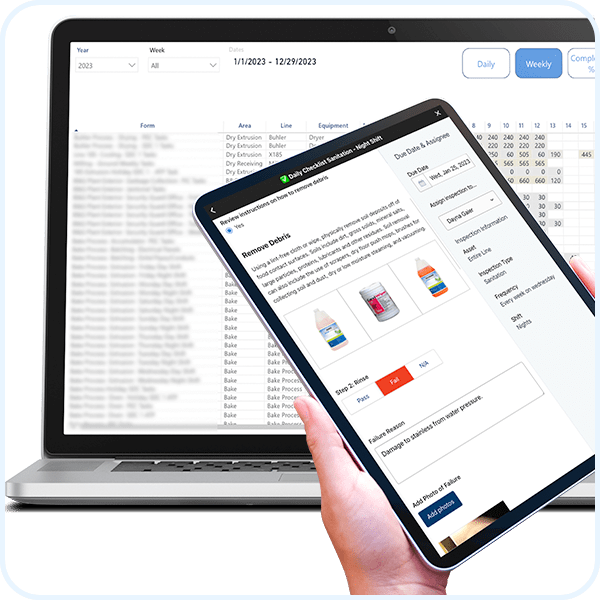

Read MoreProduction Line Cleaning & Sanitation Checklist

Set up your sanitation schedule your way and refine it as you go.

Read More6S Lean: 5S + Safety

Ensure 6S Lean (5S + Safety) audits are completed correctly including photos or video capture.

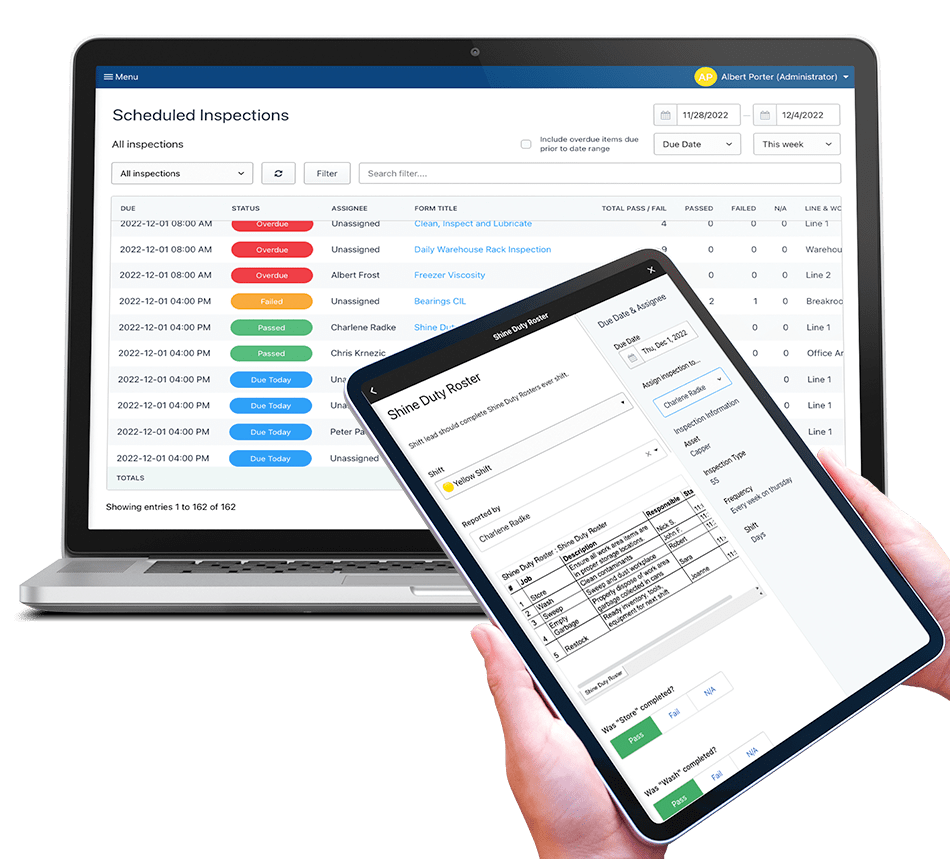

Read MoreShift Duty Roster

Manage Shift Duty Rosters to ensure tasks are getting done.

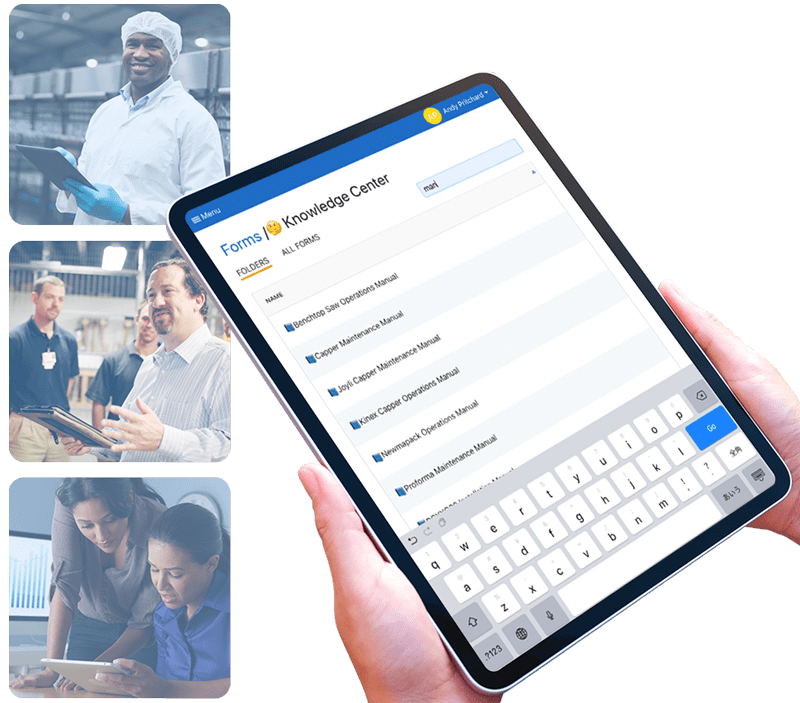

Read MoreKnowledge Center

Build a library of accessible documentation.

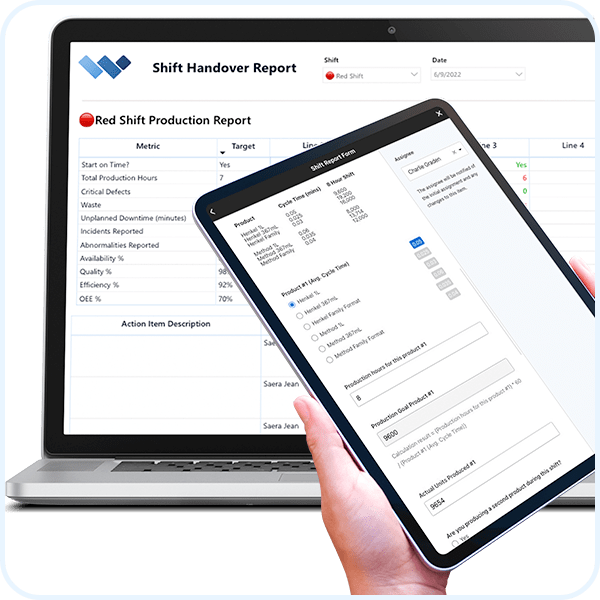

Read MoreEnd of Shift Report

Enhance communications between shifts including defects, abnormalities and commentary.

Read MoreShift Report

Comprehensive shift-to-shift reporting on production, safety, quality, maintenance, etc.

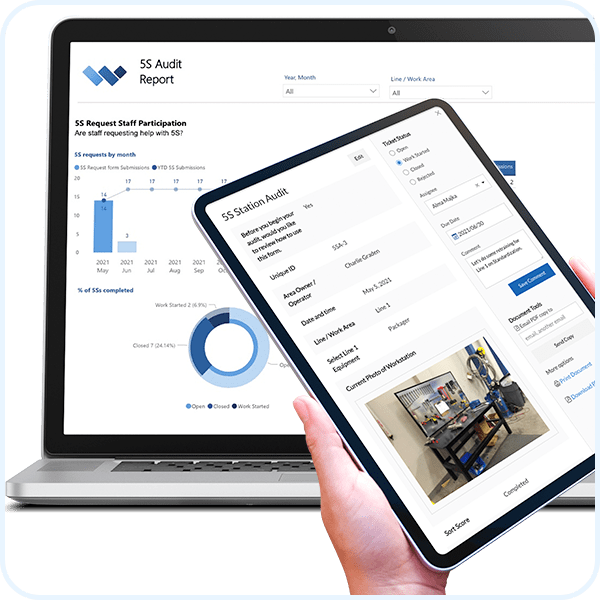

Read More5S Auditing

Ensure 5S audits are completed correctly including photos or video capture.

Read More