The Importance of Digital Data Capture

How to Unlock Manufacturing Success with Rich Frontline Data Capture

In today's rapidly evolving manufacturing landscape, success is intricately tied to the ability to adapt, optimize, and make informed decisions. For manufacturing department managers, achieving this requires a shift from traditional paper-based data capture methods to embracing digital solutions.

Digital data capture not only empowers real-time visibility but also ensures compliance with industry standards and regulations, while significantly enhancing operational efficiency.

Let’s explore the key reasons why manufacturing department managers should prioritize digital data capture to drive their department's success.

BENeFIT 1

Real-time Visibility

Real-time visibility is the cornerstone of modern manufacturing success. Manufacturing department managers need accurate, up-to-the-minute information about production processes, equipment status, and inventory levels to make timely decisions. Digital data capture plays a pivotal role in achieving real-time visibility.

Immediate Data Availability

With digital data capture systems in place, data is entered and made available instantaneously. This eliminates the lag associated with manual data entry and retrieval, ensuring that managers always have access to the most current information.

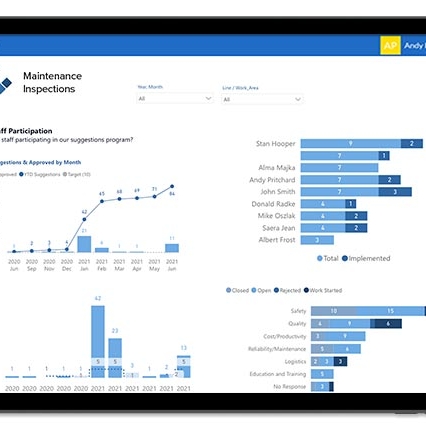

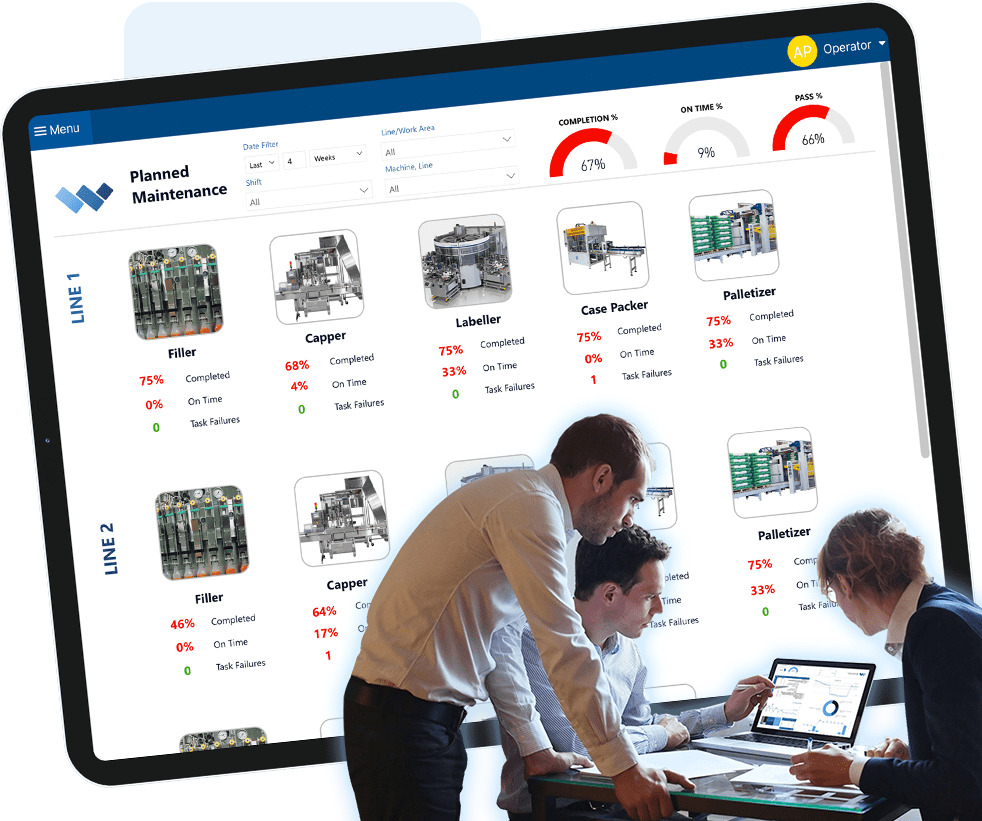

Dashboards and Analytics Automation

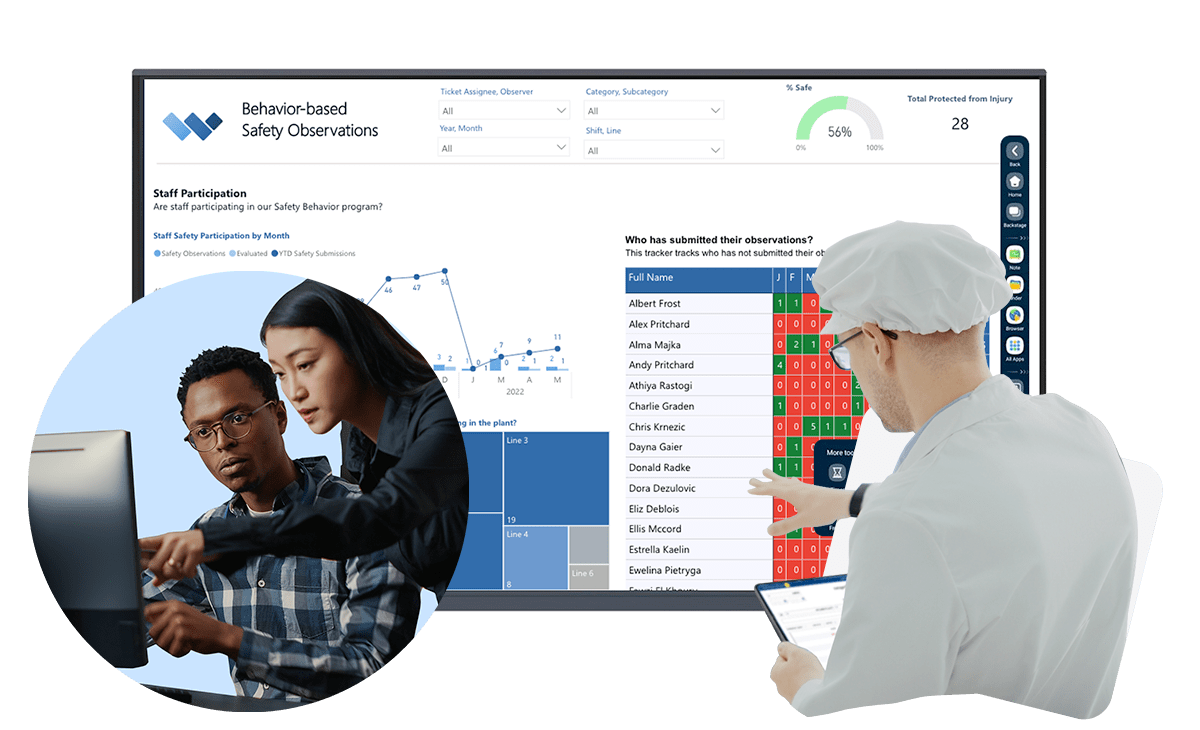

Your frontline data is automatically captured in KPI reports, which transform raw data into visual insights, providing at-a-glance information about production efficiency, quality control, and resource utilization. Real-time dashboards enable managers to spot bottlenecks, identify trends, and make data-driven decisions on the spot.

Remote Monitoring

Digital data capture allows manufacturing department managers to remotely monitor operations. Whether it's tracking machine performance, monitoring temperature and humidity levels in a storage area, or assessing inventory turnover, remote access ensures that managers can oversee operations from anywhere, enhancing responsiveness and agility.

Autonomous Operations

Digital data capture plays a pivotal role in enabling autonomous operations by providing frontline employees with seamless access to the tools, information, and resources they need to perform their tasks correctly and efficiently on a consistent basis. Learn more about Autonomous Maintenance for example.

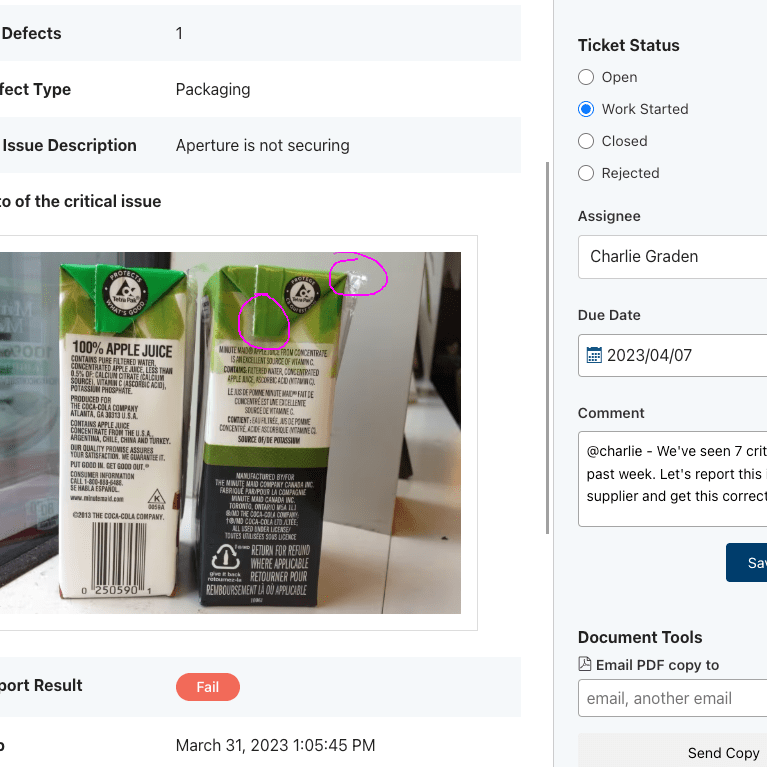

Defect & Process Deviation Visibility

Frontline employees can instantly capture data related to product defects or process deviations, which is then accessible for analysis. This transparency enables rapid identification of issues, allowing employees to take immediate corrective actions. Learn more about abnormality handling.

BENeFIT 2

Compliance

Maintaining compliance with industry regulations and quality standards is non-negotiable for manufacturing organizations. Failure to comply can result in fines, damaged reputation and health and safety issues. Digital data capture ensures both accurate task completion and the correct capture of information required for auditing purposes.

Regulatory Requirements

Compliance with industry regulations and standards is non-negotiable in manufacturing. Digital data capture ensures that your department maintains the necessary records, audits, and documentation to meet compliance requirements seamlessly.

Electronic Signatures

Many digital data capture solutions offer e-signature capabilities, making it easier to authenticate and verify data. This is invaluable for maintaining compliance records and ensuring the integrity of your documentation.

Data Integrity and Security

Digital data capture systems often include robust security features to protect sensitive data. This is essential for safeguarding proprietary information, customer data, and compliance-related records. Learn more about Weever's security measures here.

Traceability

Compliance often involves traceability, i.e., the ability to track products and materials from origin to final destination. Digital data capture provides the necessary tools to establish and maintain traceability, which is essential in industries such as aerospace, pharmaceuticals, and food production.

BENeFIT 3

Efficiency

Digital data capture streamlines data collection, eliminating manual entry and paperwork, and automates workflows, all of which dramatically increases the efficiency of factory operations.

Reduced Paperwork

Traditional paper-based data capture systems result in mountains of paperwork that must be stored, organized, and maintained. Going digital reduces this administrative burden, allowing your department to operate more efficiently and cost-effectively.

Streamlined Data Entry

Digital data capture eliminates the need for manual data entry, which is not only time-consuming but also error-prone. Employees can complete digital forms quickly and accurately, freeing up valuable time for more critical tasks.

Automated Workflows

Many digital data capture solutions offer workflow automation features. This means that once data is captured, it can trigger predefined actions or processes automatically. For example, a completed quality inspection form could prompt an immediate production adjustment if defects are detected.

In a highly competitive manufacturing environment, success hinges on your ability to adapt and thrive. Digital data capture is a powerful tool that can help you achieve this by providing real-time visibility, ensuring compliance, and enhancing operational efficiency. By embracing digital data capture solutions that offer features like real-time monitoring, compliance management, and workflow automation, you can position your department for greater success, improved product quality, and increased profitability.

"Paper work"

Weever is a comprehensive software platform that revolutionizes data capture and intelligence gathering for manufacturing organizations. Its powerful features streamline processes, enhance data accuracy, and promote better decision-making, ultimately leading to improved operational efficiency, compliance, and quality control.Weever simplifies the process of collecting data from frontline staff. With easy-to-use digital forms, employees can quickly input information, reducing the time and effort required to record critical data accurately.

Weever simplifies the process of collecting data from frontline staff. With easy-to-use digital forms, employees can quickly input information, reducing the time and effort required to record critical data accurately.

Digitize your paperwork with Weever

Weever is a software platform designed to empower manufacturing organizations by enabling them to capture data and intelligence directly from their frontline staff through simple and powerful digital forms.

Here's an overview of how Weever delivers value to manufacturing organizations:

Weever offers access to robust data analytics capabilities, allowing organizations to gain valuable insights from the data collected. This data-driven approach can lead to improved processes, cost reductions, and enhanced product quality.

With Weever, data collected from frontline staff is accessible in real-time. This feature enables managers and decision-makers to have up-to-date insights into operations, facilitating faster and more informed decision-making.

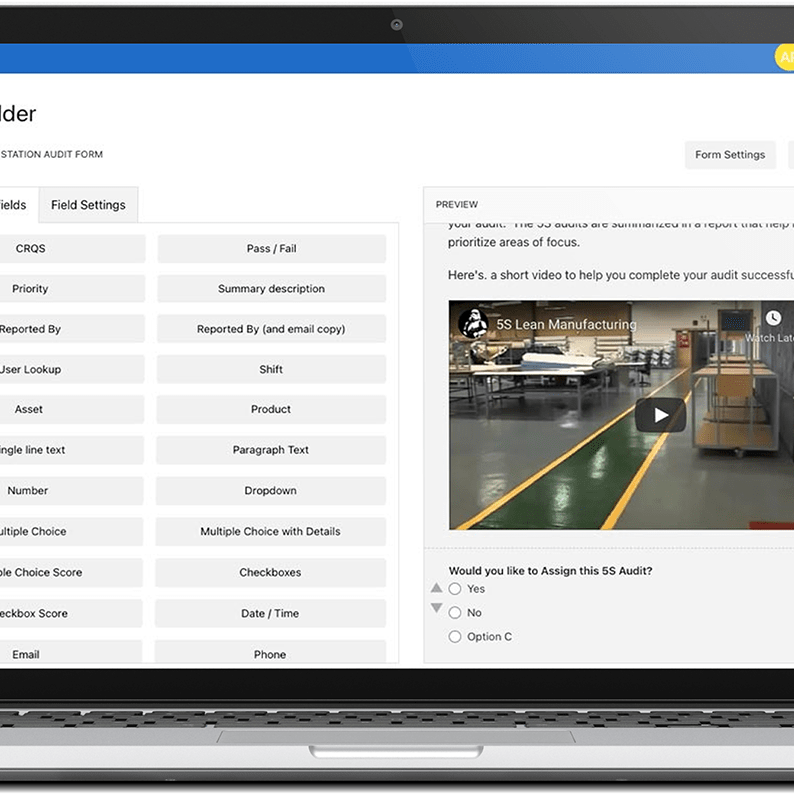

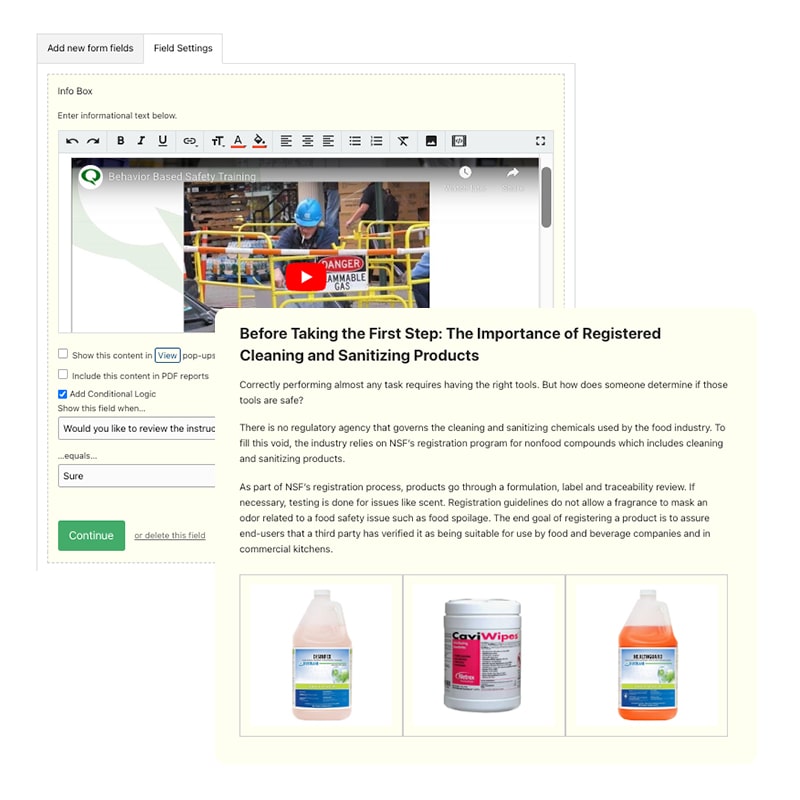

Simple and powerful form building tool makes it easy to digitize your operational forms, workflows and reports so you can customize your forms and reports to suit your unique requirements.

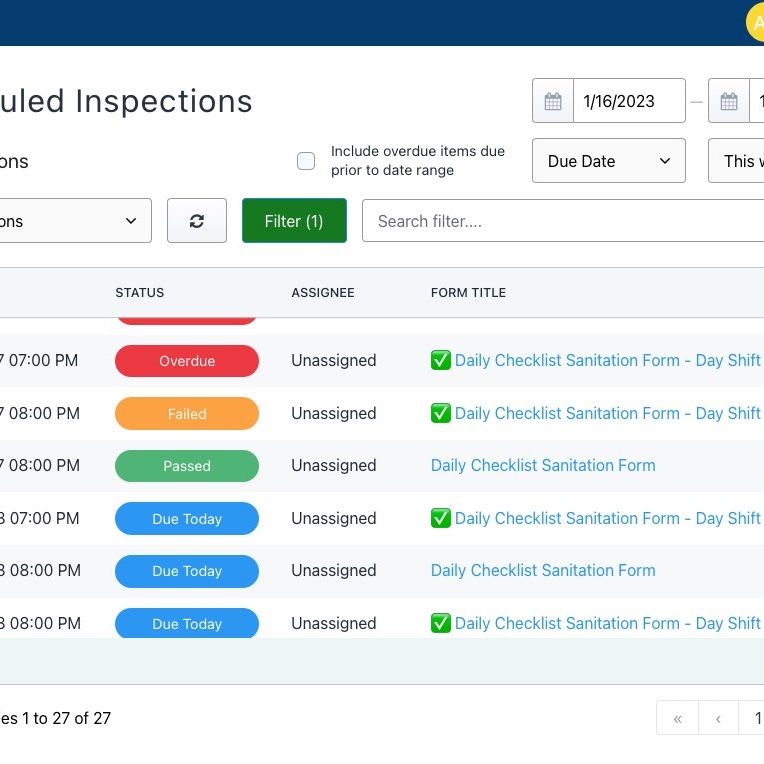

Manufacturing organizations often operate on tight schedules. Weever's schedule management feature helps frontline staff stay organized and on track by providing visibility into work schedules and task assignments. This ensures that tasks are completed on time, improving overall operational efficiency.

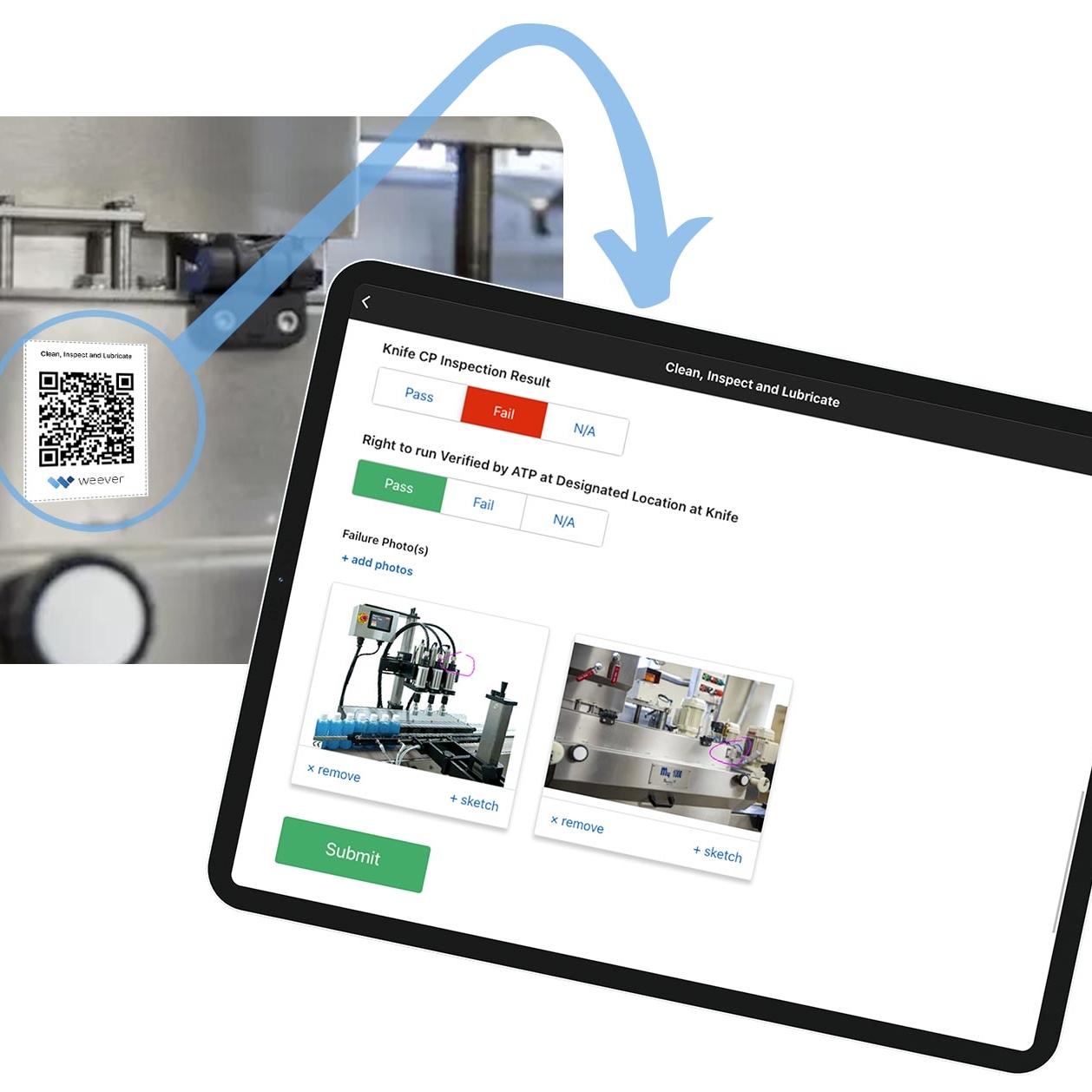

QR codes make it easy to link physical items or locations to specific forms or processes. This feature streamlines data capture by allowing employees to scan QR codes to access relevant forms, eliminating the need for manual data entry.

Weever supports digital and e-signatures, which are crucial for compliance and record-keeping in manufacturing. Employees can electronically sign off on forms and documents, reducing the reliance on paper-based processes and simplifying the audit trail.

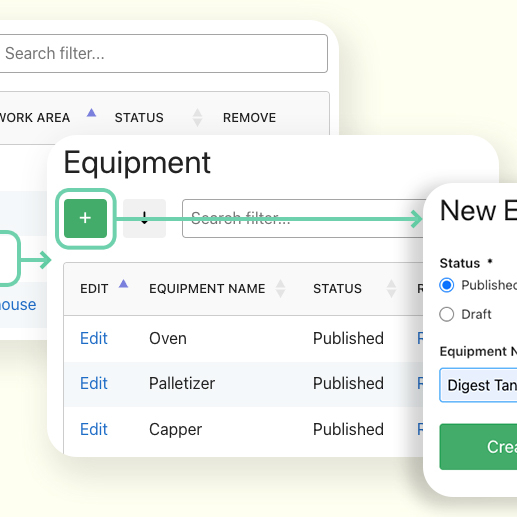

Simplify and standardize data management by maintaining a digital twin of your facility and providing a single, comprehensive list of common items, such as machines, lines, equipment, and more, which can be easily incorporated into forms, saving time and ensuring standardized reporting.

By digitizing data capture and documentation, Weever helps manufacturing organizations maintain a higher level of compliance with industry standards and regulations. This reduces the risk of costly compliance violations and quality issues.

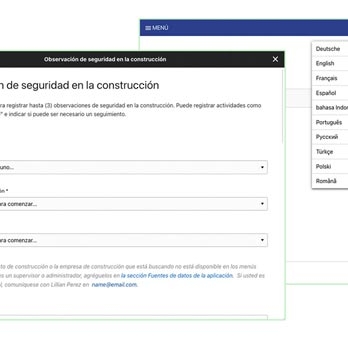

Enhance accessibility by providing additional language options. Weever supports multiple languages and additional languages can be added upon request.

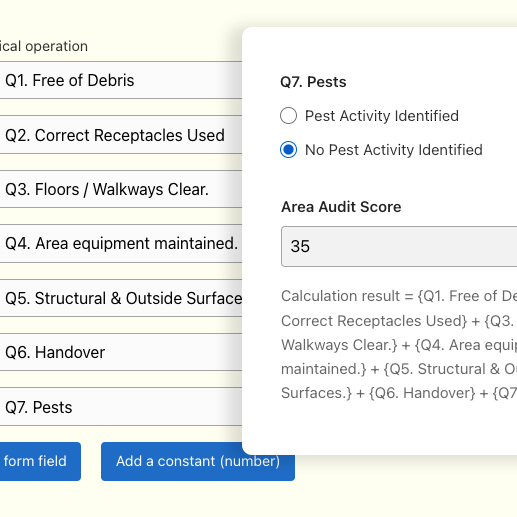

Automatically calculate anything based on user inputs. Complete complex equations. Score audits, inspections and quizzes. Qualify quantitative scores and responses. Provide information if a number is within a given range.

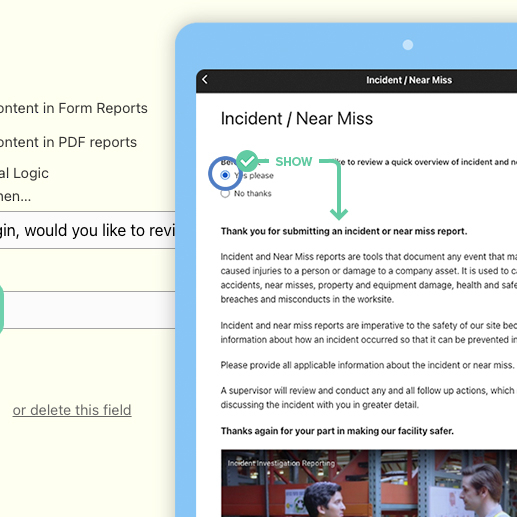

Weever's conditional logic feature enhances form flexibility. It enables the creation of dynamic forms that adapt to the specific responses provided by employees. This ensures that employees only see relevant questions, reducing errors and improving the user experience.

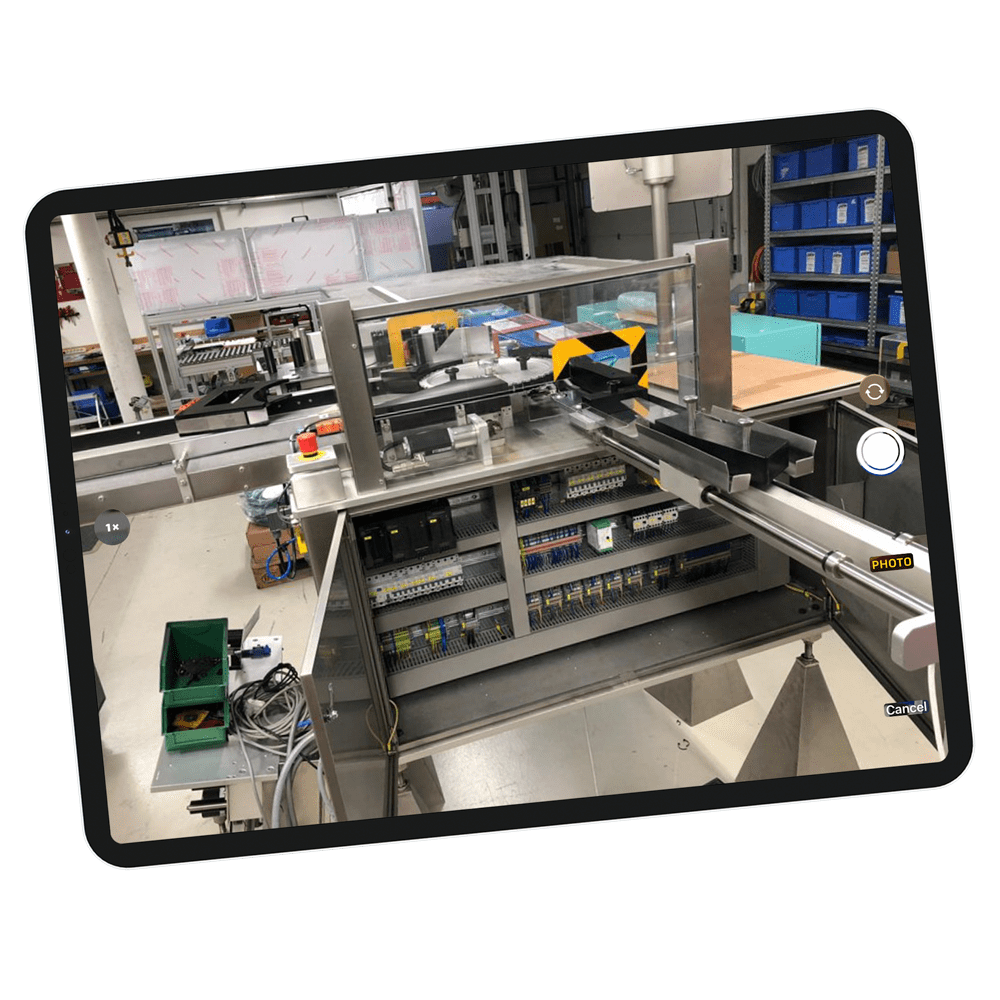

Visual data is essential in manufacturing. Weever enables staff to capture photos directly within forms. This capability is valuable for documenting equipment conditions, quality control, safety inspections, and more, enhancing the accuracy and completeness of data.

“Having cloud-based forms on devices around the facility makes them so much more accessible, which makes it painless for operators to quickly provide a report.”

Johanna Velez, VP Quality Assurance

"Weever is really user friendly and will have a massive positive impact on our operations and training team."

Mel Cadle - Op Ex Lead Process Engineer

“It’s shifted our safety culture because now we are much more focused on what we should be looking at.”

Kody Crossen, Operations Manager of EHS

bandjlogo

Bell-logo-New

Canadian-Tire-Logo

Diageo-customer-logo

greyston-bakery-logo

hello-fresh-customer

marks-customer-logo

CSL_Limited_logo

monin-logo

Winland Food

Mars-logo-main

rise-baking-customer-logo

Rockwool-Customer-Logo-min

Sportcheck-customer-logo

unilever-customer-logo

walmart-logo-small

husqvarna-customer-logo

Ajinomoto_logo

Peet's_Coffee_logo

Royal-Canin-Logo