Autonomous Maintenance Software platform

Radically improve machine performance - without the administrative burden.

Save Administration Time

Automate schedules, workflows and reporting so you can spend your time on more valuable activities.

Ensure Completion Accuracy

Enhance visibility so you know if tasks are missed and why in real-time.

Capture Insights

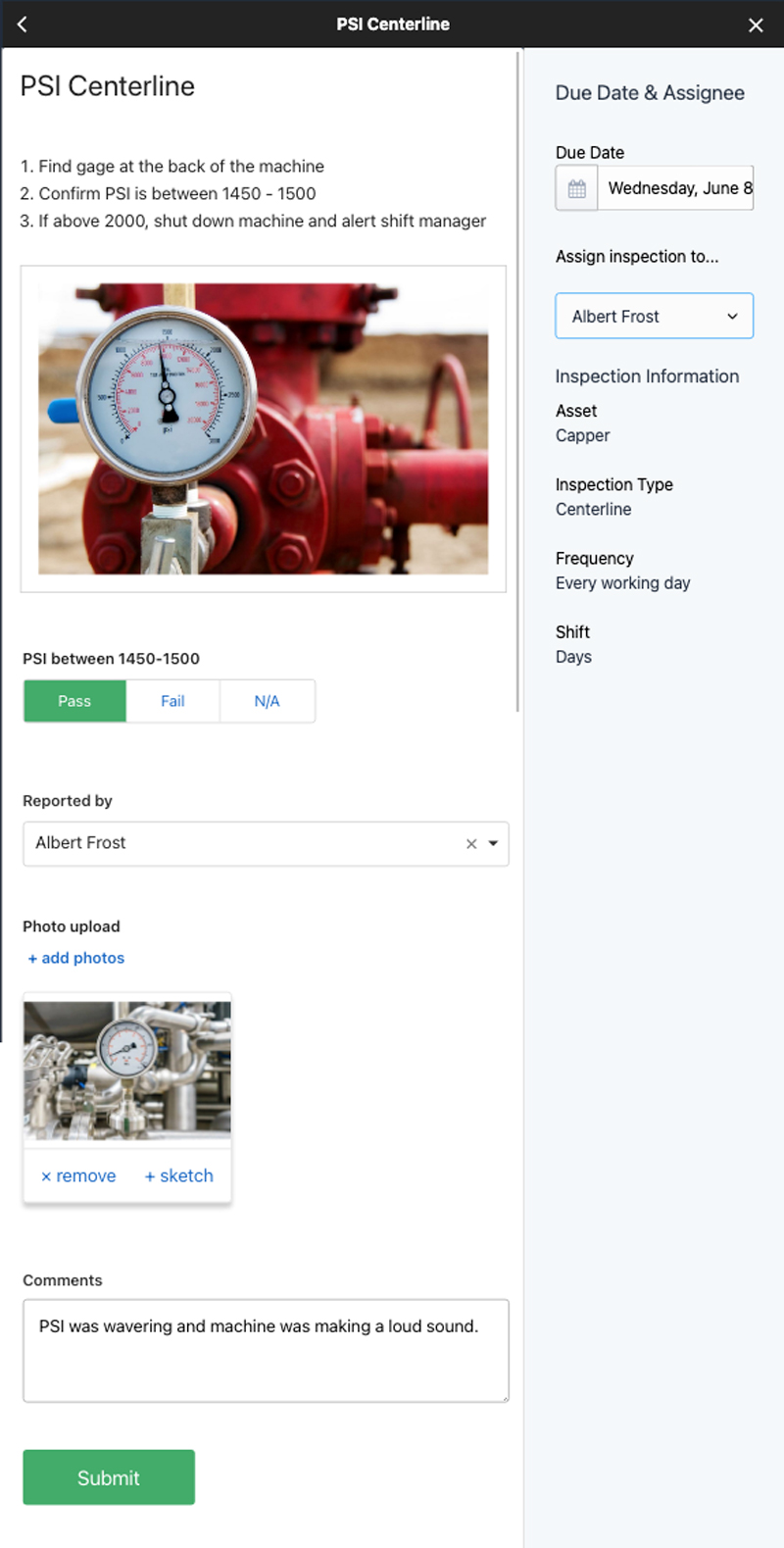

Make it easy for operators to provide rich data, including photos and videos. Automate trend and insight analysis.

Marks

Diageo

Niagara Bottling

Walmart

PepsiCo logo

McDonald's

Unilever

Monin

Hello Fresh

Rise Baking

Rockwool

Canadian Tire

SportChek

Greyston Bakery

Bell

Husqvarna

Home Hardware

What is Autonomous Maintenance?

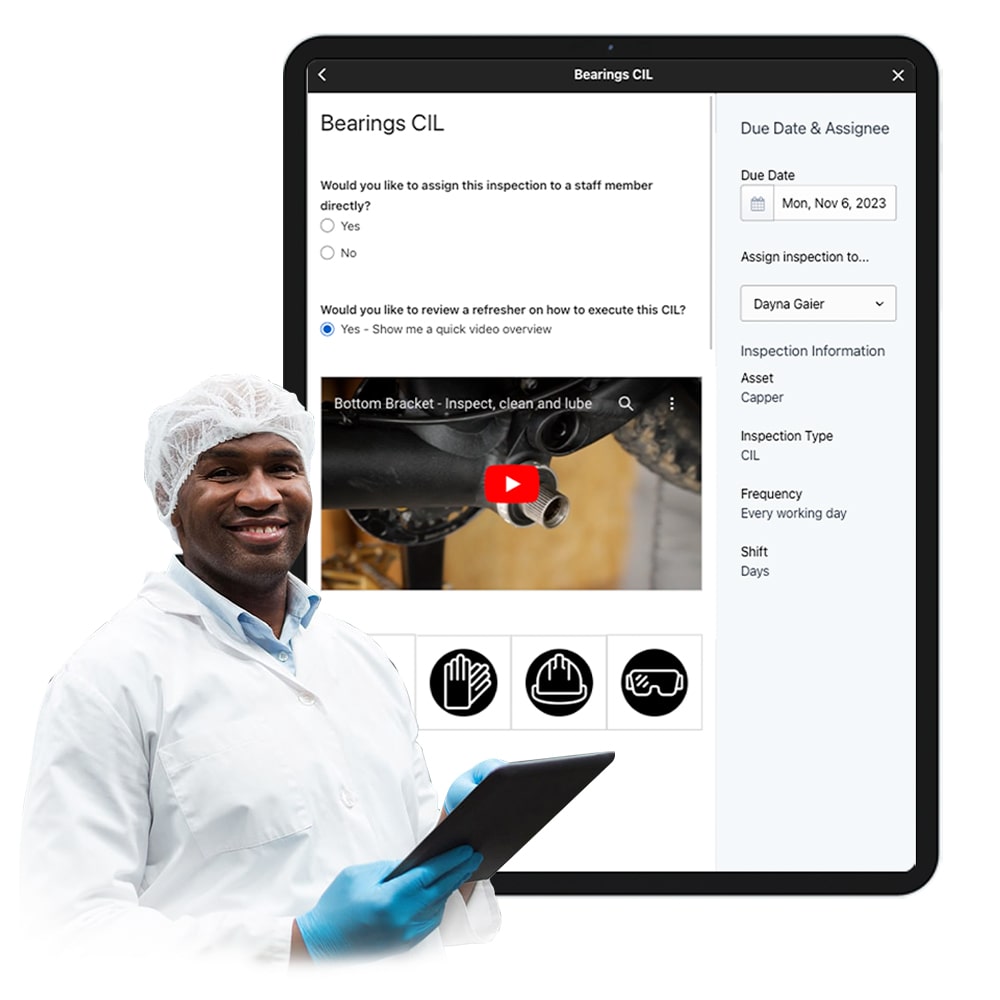

Autonomous maintenance is an approach to equipment maintenance that involves giving machine operators responsibility for basic upkeep tasks. This allows dedicated maintenance technicians to focus on more complex maintenance tasks.

Employees using equipment daily are in the best position to continually monitor it and, with training, to keep it in top working order.

Autonomous Maintenance Programs

- Schedule simple maintenance tasks.

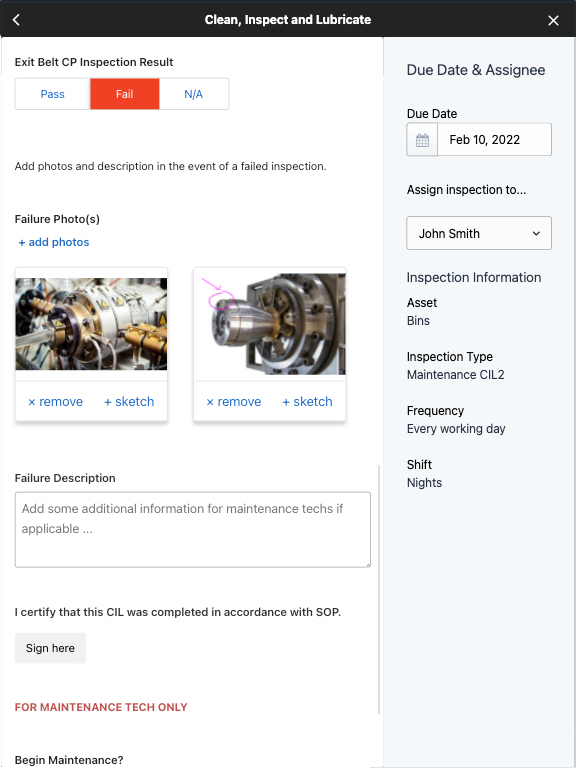

- Provide instructions including photos and videos to ensure accurate completion.

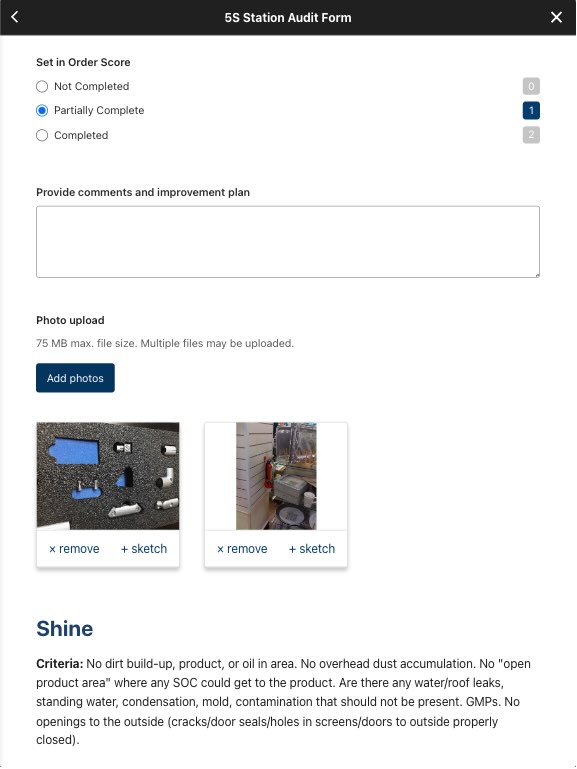

- Audit workstations to ensure compliance with 5S methodology.

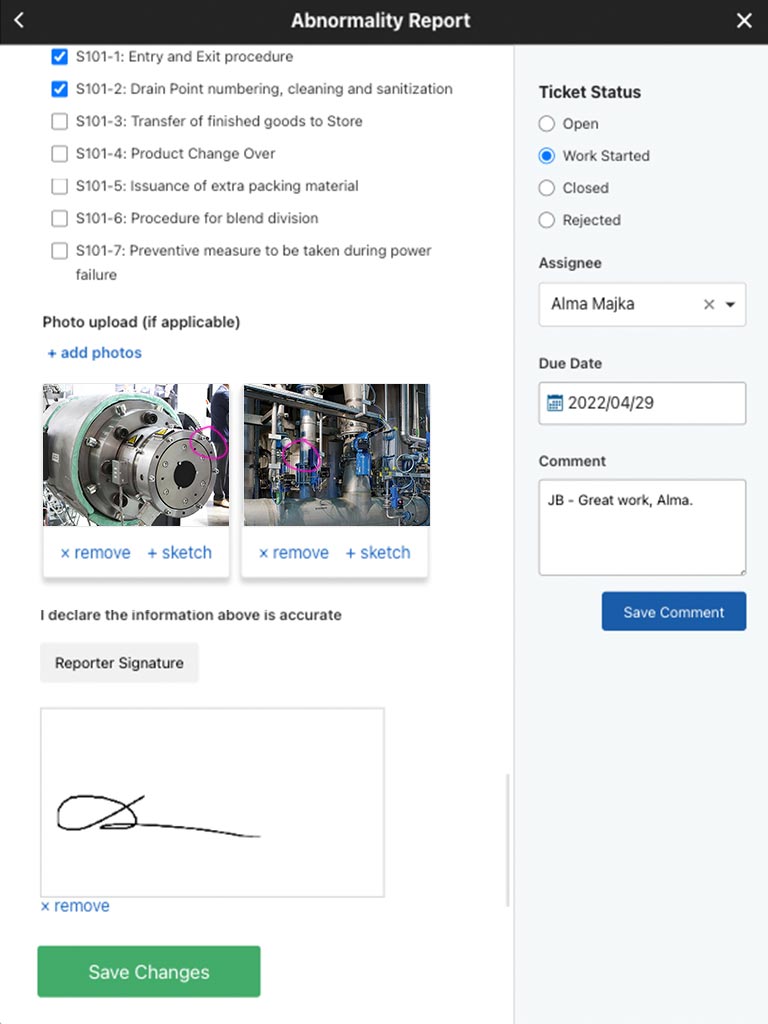

- Provide follow up action items for failures.

Automate reporting.

Discover insights, enhance visibility and motivate participation.

“I got 30% of my day back with Weever.”

CPG factory realizes massive wins through Autonomous Maintenance with Weever.

Make AM truly “Autonomous”

Before Weever, most of our customers were using manual cards and spreadsheets. They wanted to automate administration and make it easier for operators to be successful. Weever provides real-time instructions to operators, alerts supervisors on issues and missed tasks, and automates KPI dashboards, which makes your AM program more autonomous. Some of our customers were able to reallocate up to 3 full time staff by implementing Weever.

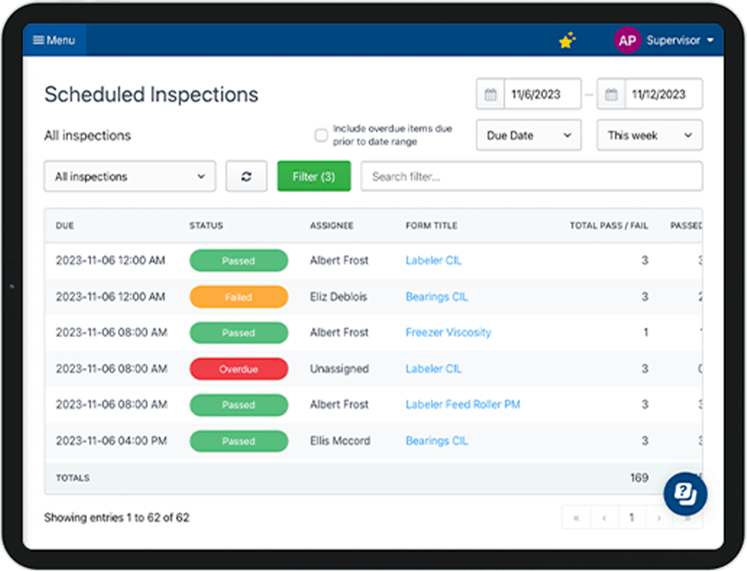

Understand where, what, when - instantly.

Enhance operational visibility so that you can react in real-time to issues. Understand where everything is at immediately, instead of waiting until the end of the shift to realize tasks were missed.

Proven Rollout Methodology

Ensure a successful implementation by leveraging our experience and proven methodology.

Lightning Fast Responses

Whether you have a question, need technical support, or are seeking guidance on optimizing your operations by using Weever, our team is always just an email away.

Support with a Human Connection

Dedicated contact. No bots or canned responses! We are here to learn your operations, and use our expertise to find the perfect solution for you.

Your Partner for Regional Standards

We help our customers standardize their operations across their organization so they can enhance visibility and ensure their regional standards are met.

Resources Galore

We have an ever-growing knowledge base to help you learn Weever features, best practices, training videos, and tips and tricks!

Schedule a demo with Weever