Best Practices

GMP Operational Audit Schedule for a Food Company

GMP Operational Audit Schedule for a Food Company Andy Pritchard | Dec 7, 2021 | 5 min read What does a standard Operational Audit Schedule for a typical food company look like? Organizations involved in the manufacturing and distribution of food are required by law to audit their processes and equipment to ensure basic…

Read MoreBest Practices to ensure success with Behaviour Based Safety Observations

Webinar Behavior Based Safety Observations Learn about Best Practices and Common Pitfalls for BBSO Behavior Based Safety Observations help organizations keep safety “top-of-mind” by continuously reinforcing and training on safety protocols and best practices. Organizations are reaping the benefits with cost savings and a safer working environment. We have identified some core challenges that our…

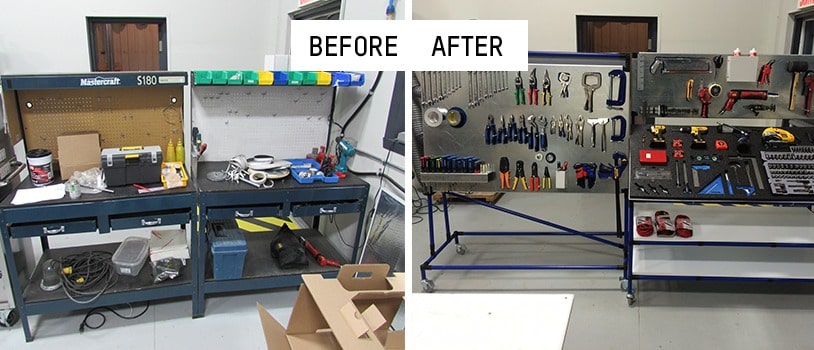

Read More5S Simple Implementation Plan

Everything you need to know about 5S including a simple implementation plan and how to sustain with a 5S auditing program.

Read More7 Tips to ensure successful 5S Audits

The steps involve the worker going through everything in a space, deciding what’s necessary and what isn’t, putting things in order, cleaning, and setting up procedures for performing these tasks on a regular basis.

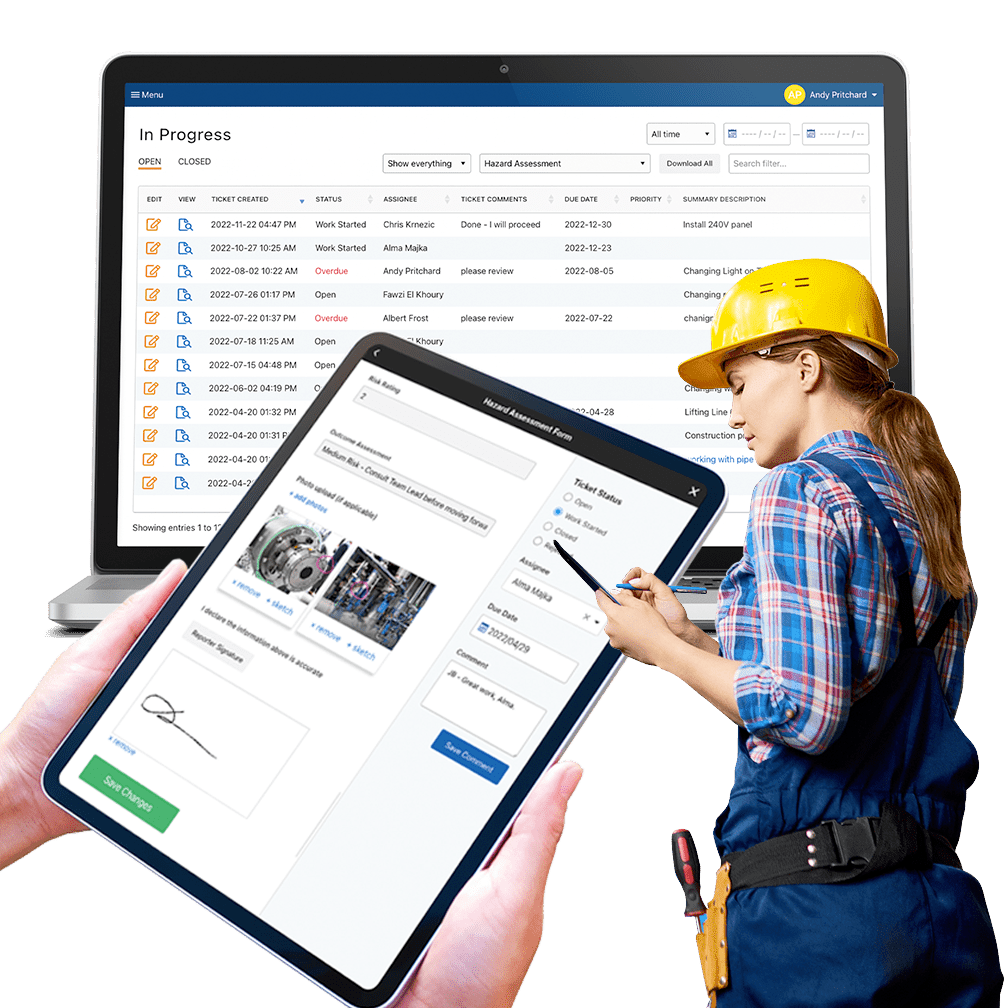

Read MoreHow to effectively manage end-of-shift reports in manufacturing

Weever is Operational Excellence Software that empowers the pursuit of perfection by enhancing operational visibility, collaboration and productivity in quality, maintenance, safety and production. This article reviews the following topics: What are end-of-shift reports and why are they valuable? Broadcast Updates Capture Data with Mobile Devices Report the Essentials and Avoid Clutter What are end-of-shift…

Read MoreConditional Number Fields – Use Cases & Best Practices

The Weever platform includes conditional number functionality. This allows administrators to reveal certain form fields only if a response to a number field is above, below or in between a given threshold. This article reviews some applicable use cases and best practices for how to set this up in your forms. Use Cases Cycle of…

Read MoreOut-of-tolerance checks best practice – conditional number fields

Autonomous Maintenance Inspections Autonomous Maintenance, a focus for many of our customers, requires machine operators to take on simple maintenance tasks (like cleaning, inspecting and lubricating components). This frees up time for the maintenance team, allowing them to focus on predictive and/or preventive measures. With conditional numbers, it is possible to provide additional required inputs…

Read MoreFactory Wi-Fi Setup

REMOTE FACTORY MANAGEMENT The recent global Covid-19 pandemic has awoken the world to the need for social distancing to combat its spread and “flatten the curve”. Manufacturing is an essential service and must continue during the outbreak of COVID-19. However, that does not necessarily mean that staff cannot socially distance within the factory walls. In…

Read More5 Tips for Remote Factory Management

Reducing employee density on the shop floor and cleaning surfaces that could infect our workforce is now a priority. As part of social distancing efforts, staff that work mostly from an office could theoretically work from home, even if it’s just part-time. The caveat of course is they need to have the resources and procedures available to do so. If done correctly it could result in fewer trips to the factory floor.

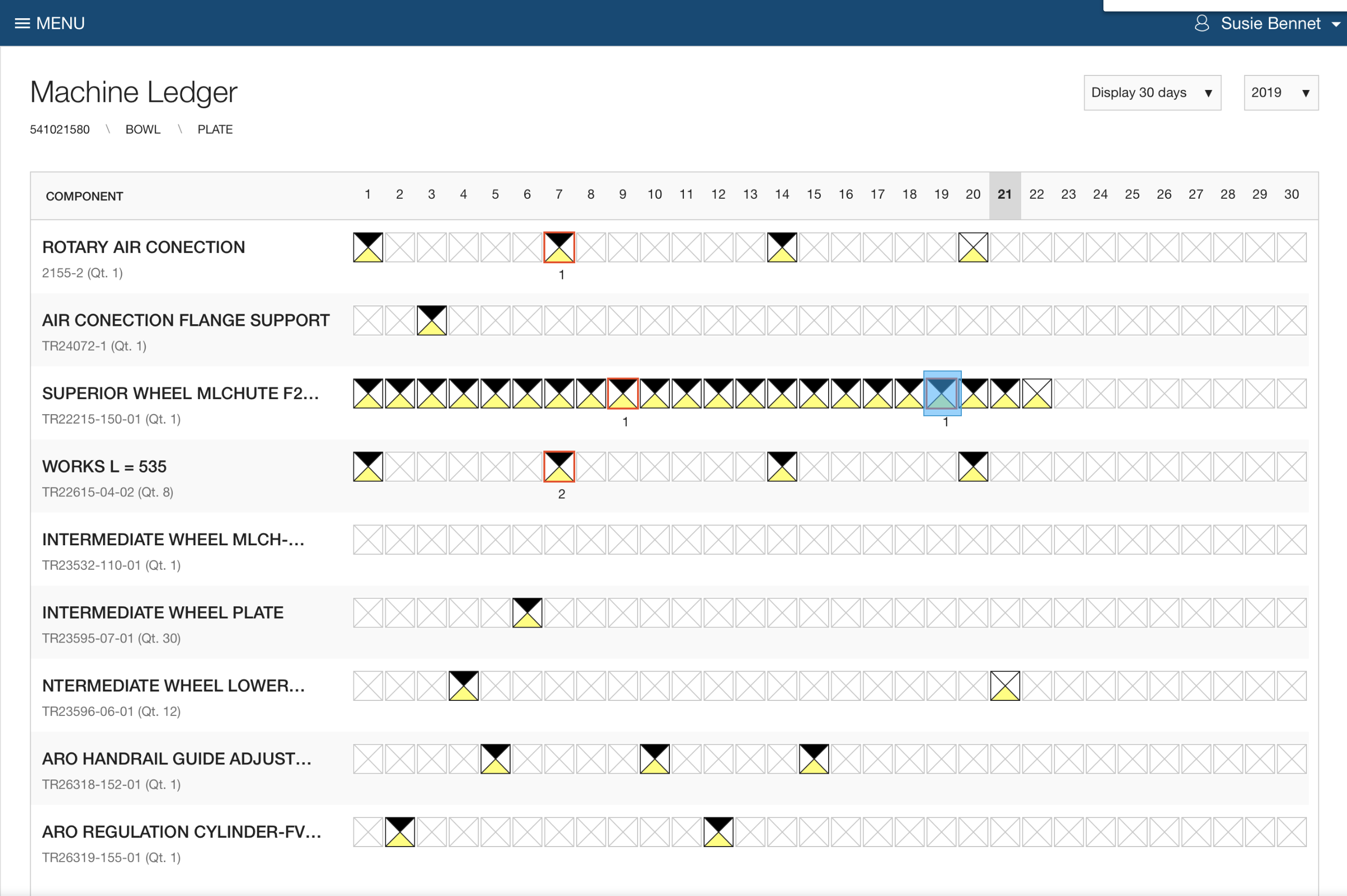

Read MoreUnderstanding the Machine Ledger

The Machine Ledger is used in World Class Manufacturing to better understand machines, sections, assemblies, and components so that maintenance teams can more effectively predict failures and plan preventive maintenance activities.

Read More