Uncategorized

The Impact of Digital Observation Forms on Employee Engagement in Manufacturing

Proactive safety is about preventing incidents before they occur. What are some simple and practical steps you can take to be more proactive now?

Read MoreTransforming Manufacturing with Integrated Work Systems: Benefits and Best Practices

Transforming Manufacturing with Integrated Work Systems: Benefits and Best Practices Transform manufacturing by making Weever part of your integrated work system. Improve communication, reduce errors, and manage resources efficiently. Integrated work systems are a powerful tool in the manufacturing industry, combining various processes, tasks, and technologies into one seamless system. These systems help manufacturers streamline…

Read MoreThe Future of Manufacturing: Leveraging Predictive Maintenance for Enhanced Efficiency

The Future of Manufacturing: Leveraging Predictive Maintenance for Enhanced Efficiency Enhance manufacturing with predictive maintenance. Learn how Weever’s software integrates data collection and analysis to not only prevent, but predict equipment failures. Predictive maintenance is a game-changer in the manufacturing industry. Unlike traditional reactive maintenance, which fixes problems after they occur, predictive maintenance anticipates issues…

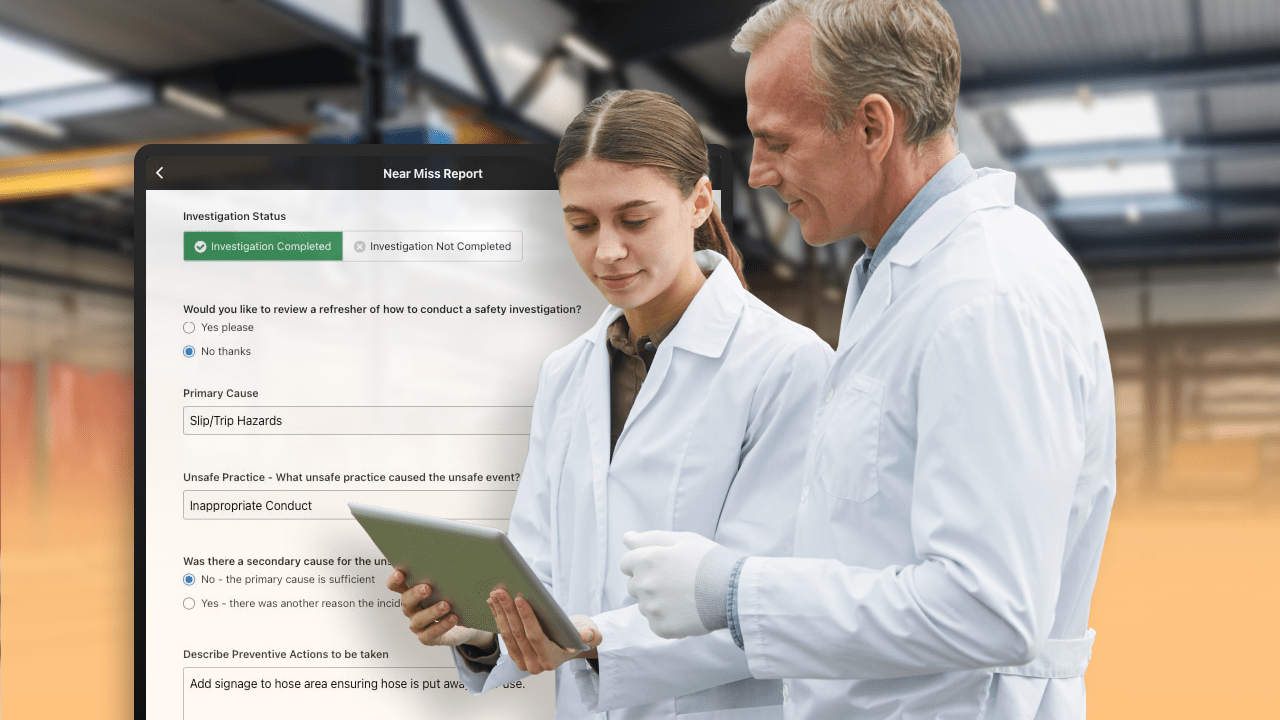

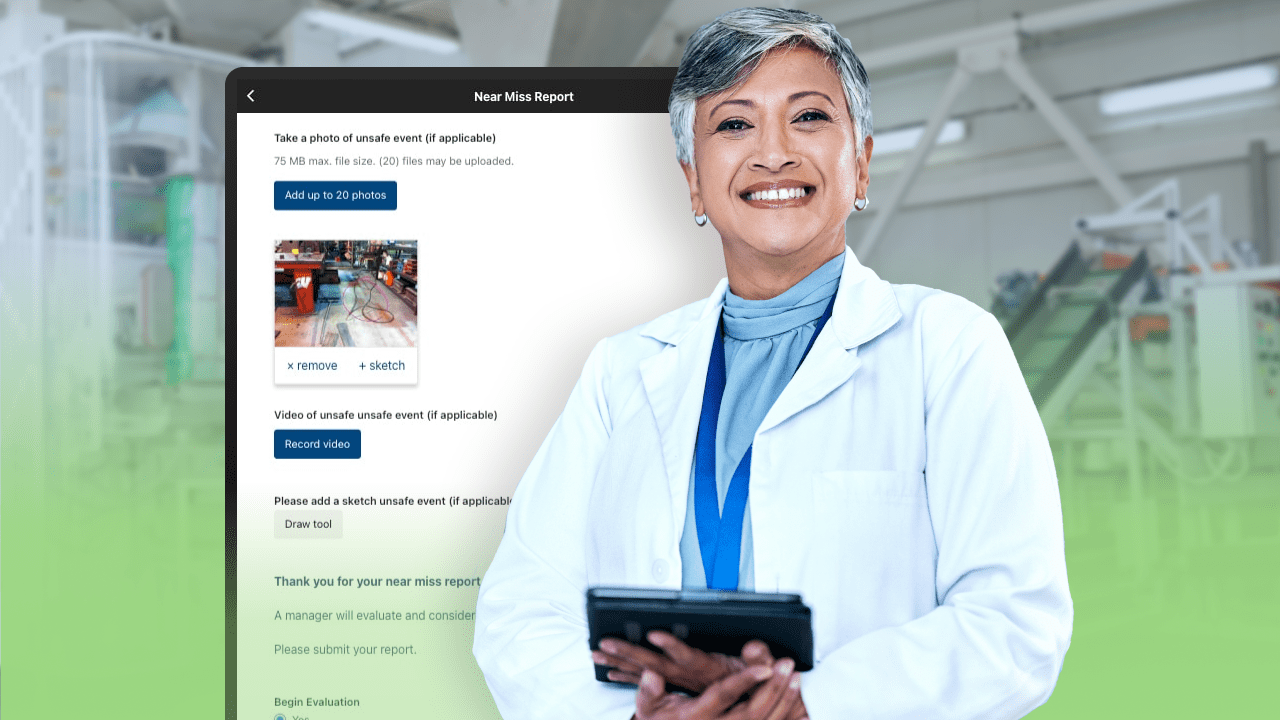

Read MoreHow Near Miss Reporting Software Can Transform Your Manufacturing Safety Culture

How Near Miss Reporting Software Can Transform Your Manufacturing Safety Culture Discover how Weever’s Near Miss Reporting software transforms manufacturing safety with digital data capture, automated tasks, and real-time insights for a proactive safety culture. Safety in manufacturing is crucial for protecting employees and maintaining efficient operations. Weever’s Near Miss Reporting software helps identify and…

Read MoreTop Features in Near Miss Reporting Software for Manufacturing

Top Features in Near Miss Reporting Software for Manufacturing Discover top features in near miss reporting software for manufacturing. Learn how Weever’s solutions improve safety, streamline reporting, and boost efficiency. In manufacturing, near miss reporting software is crucial for preventing accidents and enhancing safety. By capturing and analyzing incidents that almost led to accidents, manufacturers…

Read MoreHow Proactive Measures Can Lead to Cost Savings in Manufacturing

Proactive safety is about preventing incidents before they occur. What are some simple and practical steps you can take to be more proactive now?

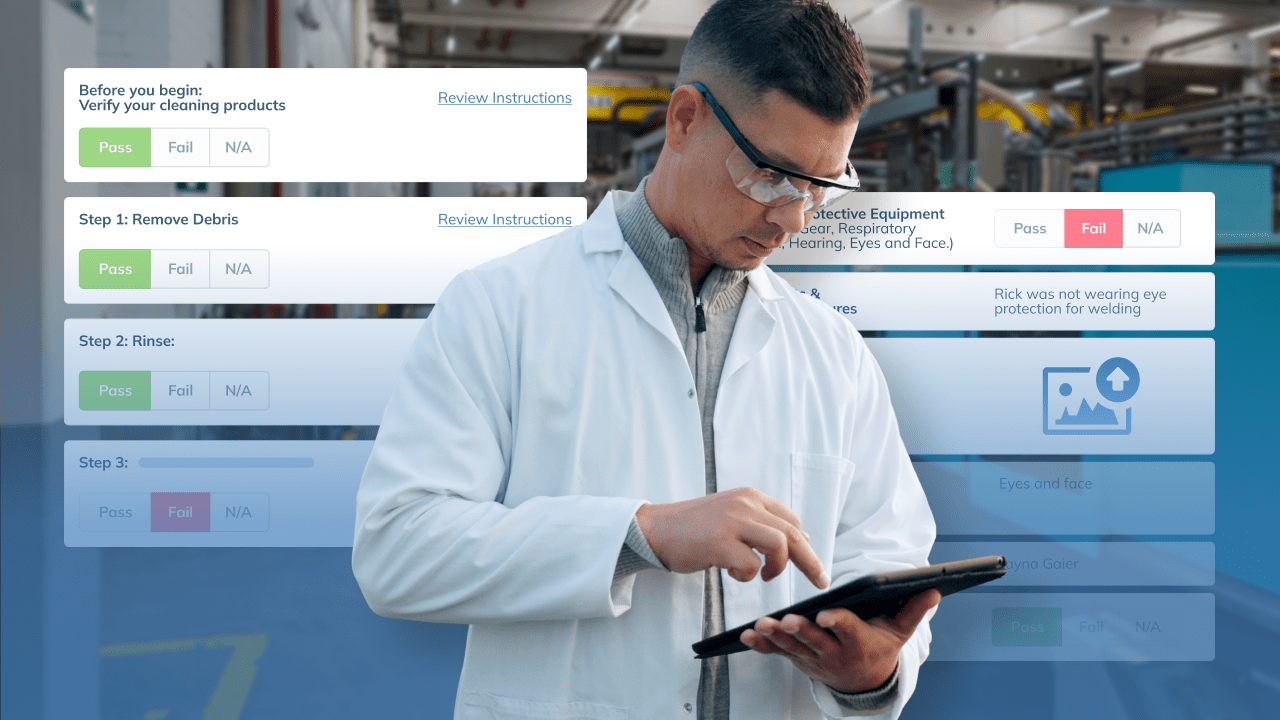

Read MoreBest Practices for Manufacturers Developing Your Audit Checklist

Scheduled 5S audits are by far the most critical factor in the Sustain element of the 5S methodology. This post provides a step-by-step overview of how to set up your 5S auditing program for success.

Read MoreTransforming Safety Reporting with Weever’s Digital Solution

Discover why Kody has found Weever, an innovative operations management software platform specializing in Food and CPG manufacturing, to be an indispensable tool for managing Walmart’s BBSO program.

Read MoreInfo Request 5S Thank you

Erradicate 90% of facility safety incidents, which are caused by at-risk behaviors, not conditions. Provide accessible tools to ensure success. Real-time reporting and workflow management.

Read MoreHow to Build a 5S Implementation Roadmap

Crafting an implementation plan or roadmap is pivotal to ensure a smooth transition and successful adoption of 5S principles.

Read More