Uncategorized

Why is Weever Software Essential for Aligning Sanitation Scheduling with Autonomous Maintenance in Manufacturing?

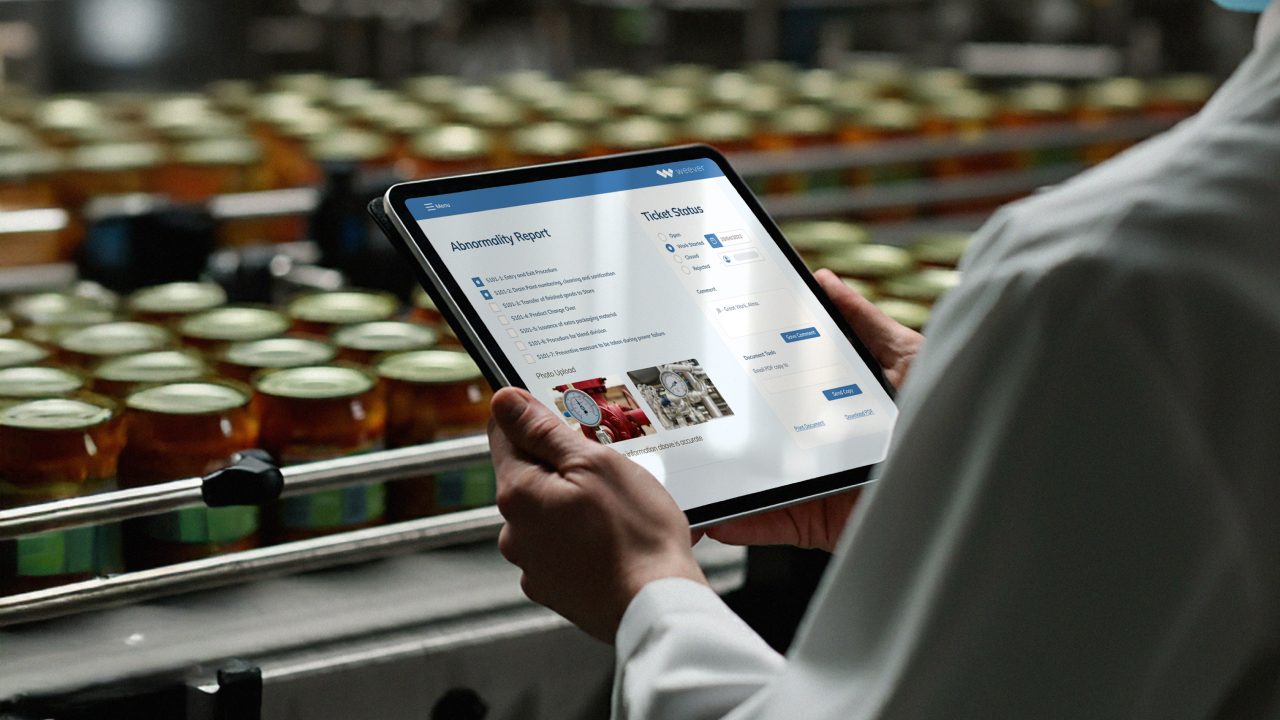

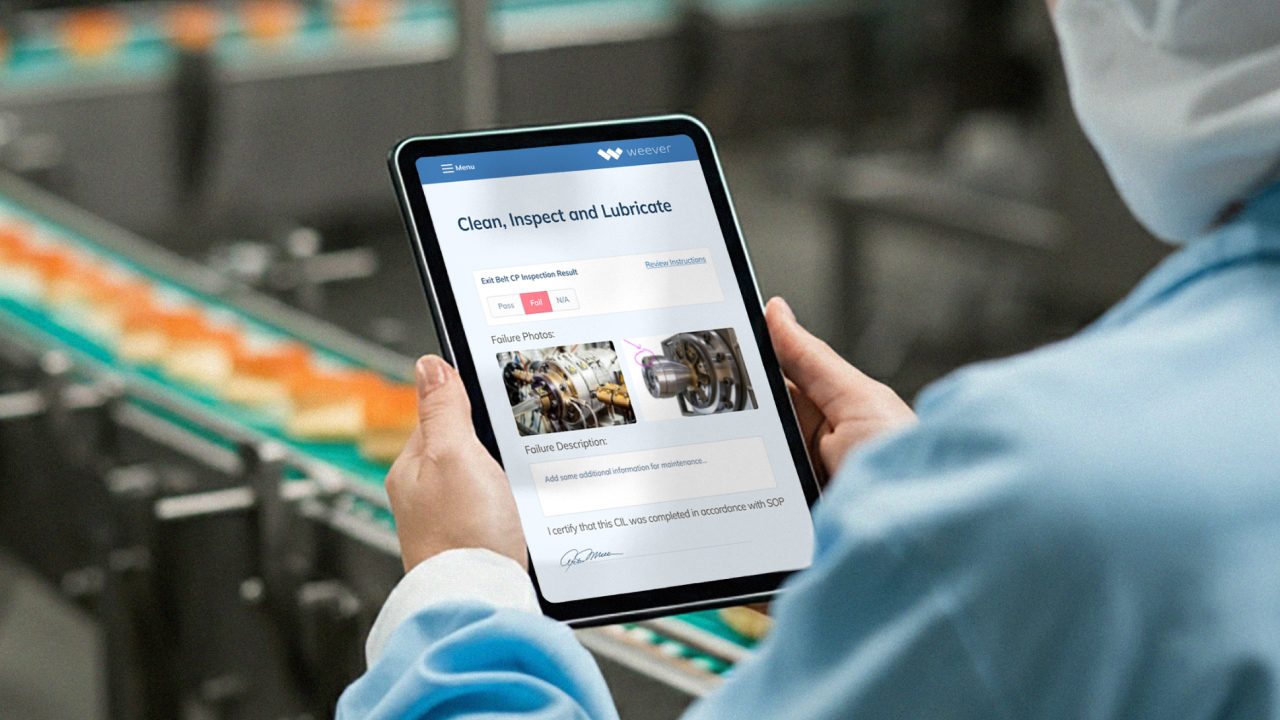

Why is Weever Software Essential for Aligning Sanitation Scheduling with Autonomous Maintenance in Manufacturing? Streamline sanitation and maintenance with Weever software. Align schedules, automate workflows, and boost efficiency in manufacturing. Aligning sanitation scheduling with autonomous maintenance is critical for maintaining efficiency and compliance. Autonomous maintenance empowers operators to take ownership of routine equipment upkeep, while…

Read MoreHow Does Weever Software Help Manufacturing Plants Achieve Audit Readiness with Master Sanitation Schedules?

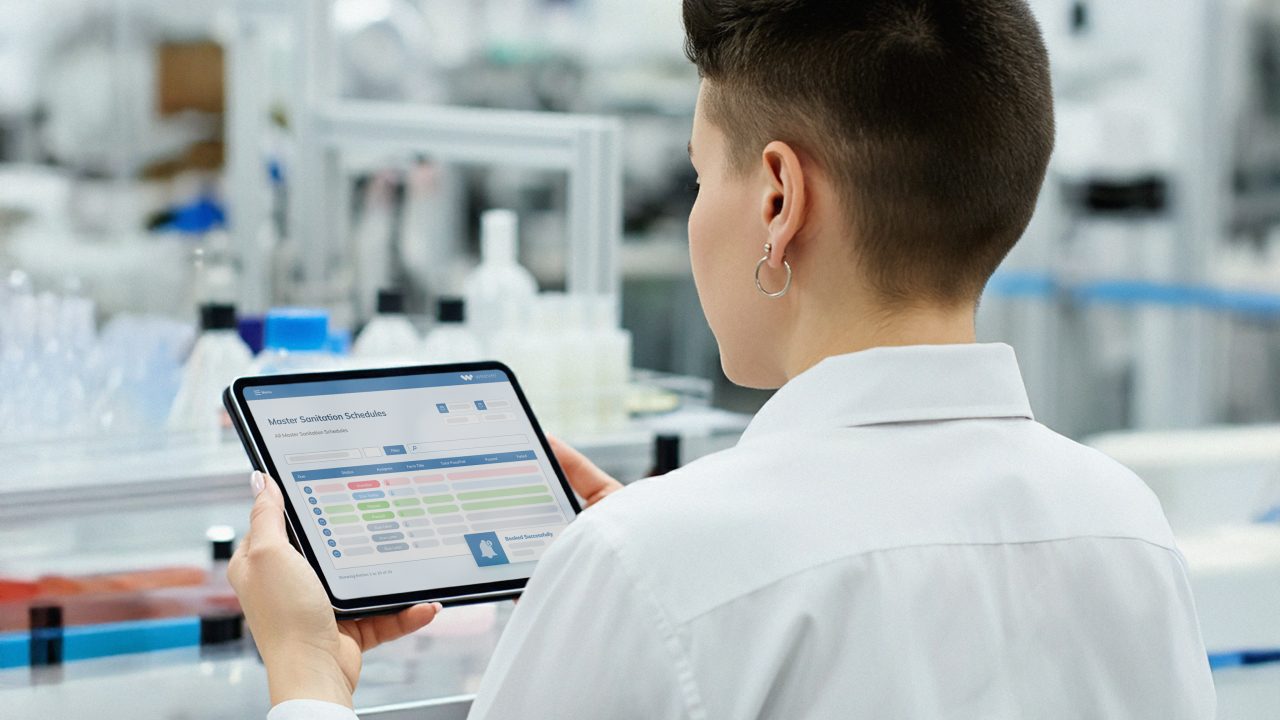

How Does Weever Software Help Manufacturing Plants Achieve Audit Readiness with Master Sanitation Schedules? Achieve audit readiness with Weever! Streamline master sanitation schedules, automate workflows, and ensure compliance in food and beverage manufacturing. Maintaining a clean and compliant production environment is non-negotiable in food and beverage manufacturing. A well-executed Master Sanitation Schedule (MSS) is essential…

Read MoreHow Does Weever Software Enhance Food Safety and Support Autonomous Maintenance in Manufacturing?

How Does Weever Software Enhance Food Safety and Support Autonomous Maintenance in Manufacturing? Enhance food safety and equipment reliability with Weever’s master sanitation schedules and autonomous maintenance programs. Food safety and equipment reliability are critical in manufacturing environments, particularly in the food and beverage sector where contamination risks and downtime can significantly impact operations. To…

Read MoreHow a Smart Sanitation Schedule Transforms Food Manufacturing

How a Smart Sanitation Schedule Transforms Food Manufacturing Explore how Weever’s configurable MSS boosts food manufacturing efficiency and compliance. Food manufacturers operate in a high-stakes environment, where a single misstep in sanitation can lead to severe consequences. From costly product recalls and damaged brand reputations to potential health risks for consumers, the cost of non-compliance…

Read MoreHow Does Weever Software Support Configurable Master Sanitation Schedules for Food Manufacturing Plants?

How Does Weever Software Support Configurable Master Sanitation Schedules for Food Manufacturing Plants? Streamline food safety with Weever’s configurable MSS. Automate, customize, and optimize cleaning schedules for compliance, efficiency, and quality. Managing cleanliness and sanitation in food manufacturing plants is critical for maintaining food safety, ensuring compliance with industry regulations, and safeguarding product quality. A…

Read MoreWhat Are the Best Practices for a Master Sanitation Schedule, and How Does Weever Simplify Compliance for Manufacturers?

What Are the Best Practices for a Master Sanitation Schedule, and How Does Weever Simplify Compliance for Manufacturers? Streamline sanitation compliance with Weever’s MSS solution. Automate schedules, track cleaning tasks, and gain insights into food manufacturing safety and efficiency. A well-structured master sanitation schedule (MSS) is a cornerstone of effective sanitation management in food and…

Read MoreHow Does Weever Software Streamline Planned Cleaning in Food Production?

How Does Weever Software Streamline Planned Cleaning in Food Production? Streamline sanitation in food production with Weever. Automate cleaning schedules, track performance, and ensure compliance with real-time insights. In the food production and related industries, maintaining cleanliness is a non-negotiable priority. Effective sanitation ensures compliance with regulatory requirements, safeguards product quality, and upholds consumer trust.…

Read MoreHow Does Weever Software Simplify Tracking the Frequency of Cleaning in Manufacturing Plants?

How Does Weever Software Simplify Tracking the Frequency of Cleaning in Manufacturing Plants? Streamline cleaning schedules with Weever. Automate tasks, track cleaning frequency, and gain insights to enhance compliance and efficiency in manufacturing. Maintaining cleanliness and sanitation is more than a regulatory requirement-it’s a critical factor for ensuring product quality, operational efficiency, and food safety.…

Read MoreWhy Weever Software is the Optimal Tool for Your Master Sanitation Program

Why Weever Software is the Optimal Tool for Your Master Sanitation Program Discover why Weever is the top choice for implementing a Master Sanitation Program in manufacturing. Ensuring top-notch cleanliness and compliance in the food manufacturing sector requires a robust Master Sanitation Schedule (MSS). The complexity of managing scheduled cleanings and equipment maintenance in such…

Read More5S Audits Made Simple with Weever: Creating a More Efficient Real-Time Workplace

Proactive safety is about preventing incidents before they occur. What are some simple and practical steps you can take to be more proactive now?

Read More