Uncategorized

Tracking and Reporting Abnormalities and Defects in Real-Time with Weever

Tracking and Reporting Abnormalities and Defects in Real-Time with Weever Optimize manufacturing with Weever’s real-time abnormality and defect tracking. Detect, report, and resolve issues instantly to minimize disruptions and enhance efficiency. Identifying and addressing abnormalities and defects quickly is essential to maintaining smooth operations and high-quality standards for manufacturers. Delays in resolving issues can disrupt…

Read MoreOperator-Led CIL Training with Weever: Bridging Knowledge Gaps Across Different Manufacturing Industries

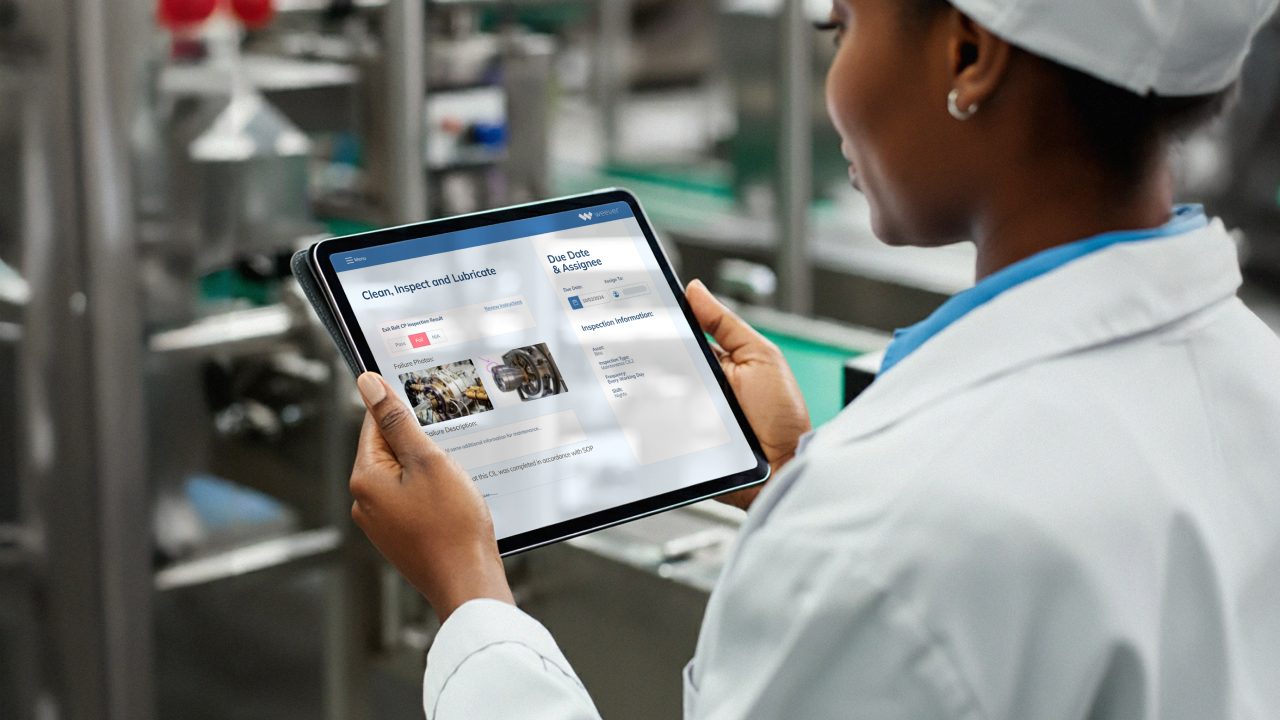

Operator-Led CIL Training with Weever: Bridging Knowledge Gaps Across Different Manufacturing Industries Discover how Weever simplifies operator-led CIL training to bridge knowledge gaps, ensuring consistent, efficient maintenance across manufacturing industries. In the manufacturing industry, keeping equipment in optimal working condition is crucial for maintaining operational efficiency. Cleaning, Inspection, and Lubrication (CIL) routines are a core…

Read MoreStandardizing CIL Standard Operating Procedures (SOPs) with Weever

Standardizing CIL Standard Operating Procedures (SOPs) with Weever Discover how Weever simplifies and standardizes CIL SOPs for manufacturing plants, improving equipment maintenance, reducing downtime, and boosting efficiency. Maintaining equipment through regular cleaning, inspection, and lubrication (CIL) is critical for ensuring optimal performance and minimizing downtime in the manufacturing industry. To achieve consistency and precision in…

Read MoreHow Can Manufacturing Plants Create Efficient CIL Checklists Using Weever?

How Can Manufacturing Plants Create Efficient CIL Checklists Using Weever? Learn how Weever helps manufacturing plants create efficient CIL checklists to streamline maintenance, reduce downtime, and improve overall equipment effectiveness. In the manufacturing industry, equipment downtime can lead to significant financial losses, production delays, and reduced operational efficiency. Effective maintenance routines are essential to keeping…

Read MoreTracking CIL with Weever’s Connected Worker Platform: Real-Time Monitoring for Manufacturers

Tracking CIL with Weever’s Connected Worker Platform: Real-Time Monitoring for Manufacturers Enhance CIL tracking with Weever’s Connected Worker Platform. Automate tasks, monitor real-time progress, and improve equipment efficiency for manufacturers. Manufacturing industries rely heavily on maintaining equipment efficiency and minimizing downtime to stay competitive. Ensuring that machines are properly cleaned, inspected, and lubricated (CIL) is…

Read MoreHow Weever Automates CIL Tasks to Streamline Maintenance Efficiency

How Weever Automates CIL Tasks to Streamline Maintenance Efficiency Discover how Weever’s visual controls simplify CIL processes, guiding operators to complete maintenance tasks efficiently while improving performance tracking. Today, maximizing efficiency in manufacturing is key to maintaining a competitive edge. One area where inefficiencies often arise is in the management of Cleaning, Inspection, and Lubrication…

Read MoreDecentralized Maintenance: Boosting Efficiency with Weever’s Customizable Solutions

Decentralized Maintenance: Boosting Efficiency with Weever’s Customizable Solutions Boost efficiency with Weever’s customizable solutions for decentralized maintenance. Automate workflows, track tasks, and ensure consistency across multiple locations. Efficient maintenance practices are critical to ensuring smooth operations, minimizing equipment downtime, and preventing costly breakdowns. Decentralized maintenance is becoming an increasingly popular strategy for improving maintenance efficiency…

Read MoreHow Frontline Workers Can Streamline Maintenance Routines Using Weever’s Connected Worker Platform

How Frontline Workers Can Streamline Maintenance Routines Using Weever’s Connected Worker Platform Streamline maintenance routines with Weever’s Connected Worker Platform. Empower frontline workers with automated workflows, real-time reporting, and visual task controls. In industries such as food production, retail, logistics, and healthcare, maintaining smooth operations and reducing downtime are critical to success. However, managing maintenance…

Read MoreSimplifying Preventive Maintenance by Operators with Weever’s Automated Workflows

Simplifying Preventive Maintenance by Operators with Weever’s Automated Workflows Streamline preventive maintenance with Weever’s automated workflows. Empower frontline workers to efficiently manage cleaning, inspections, and equipment upkeep. Operator-led maintenance has emerged as a key strategy to empower frontline workers to take control of routine maintenance tasks, such as cleaning, inspecting, and lubricating equipment. This decentralized…

Read MoreEmpowering Operator-Led Maintenance with Weever: Enhancing Productivity in Manufacturing

Empowering Operator-Led Maintenance with Weever: Enhancing Productivity in Manufacturing Discover how Weever empowers operator-led maintenance across retail, logistics, and healthcare with automation, real-time insights, and efficient rollout methodologies. Operator-led maintenance is widely recognized for its transformative impact on the manufacturing industry. By empowering frontline workers to take ownership of routine maintenance tasks-such as cleaning, inspecting,…

Read More