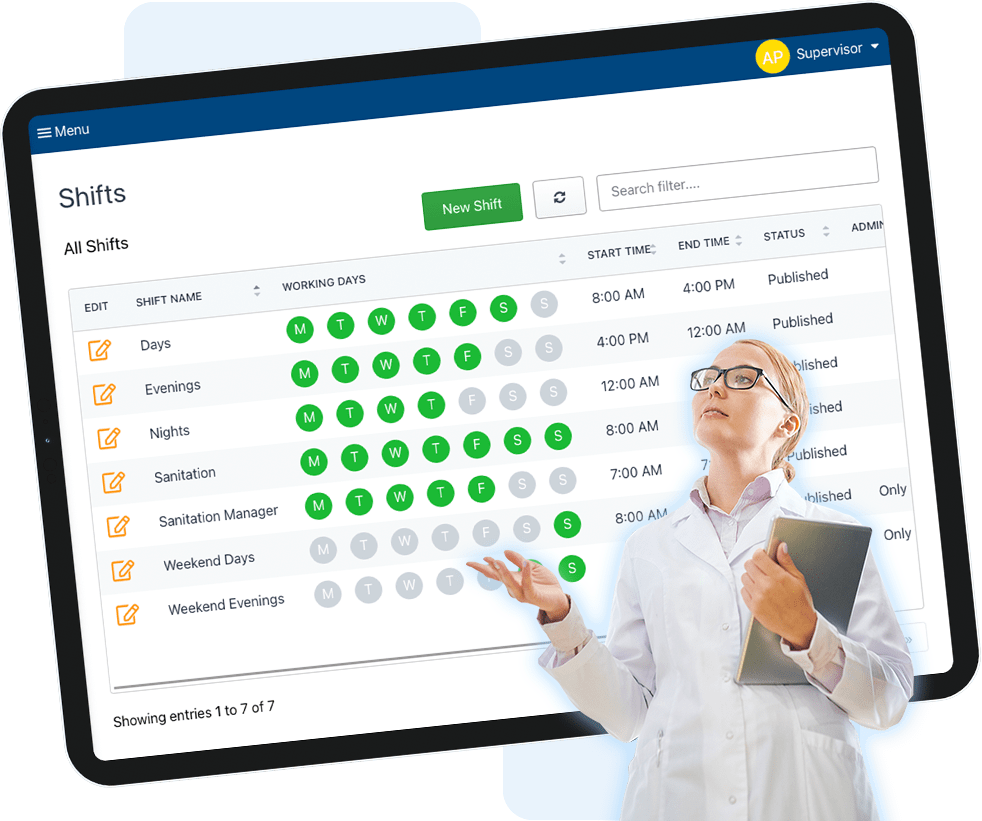

SHIFT MANAGEMENT

Set it and forget it.

Create and manage a list of shifts for your site. Easily adapt schedules to suit changes in shifts.

bandjlogo

Bell-logo-New

Canadian-Tire-Logo

Diageo-customer-logo

greyston-bakery-logo

hello-fresh-customer

marks-customer-logo

CSL_Limited_logo

monin-logo

Winland Food

Mars-logo-main

rise-baking-customer-logo

Rockwool-Customer-Logo-min

Sportcheck-customer-logo

unilever-customer-logo

walmart-logo-small

husqvarna-customer-logo

Ajinomoto_logo

Peet's_Coffee_logo

Royal-Canin-Logo

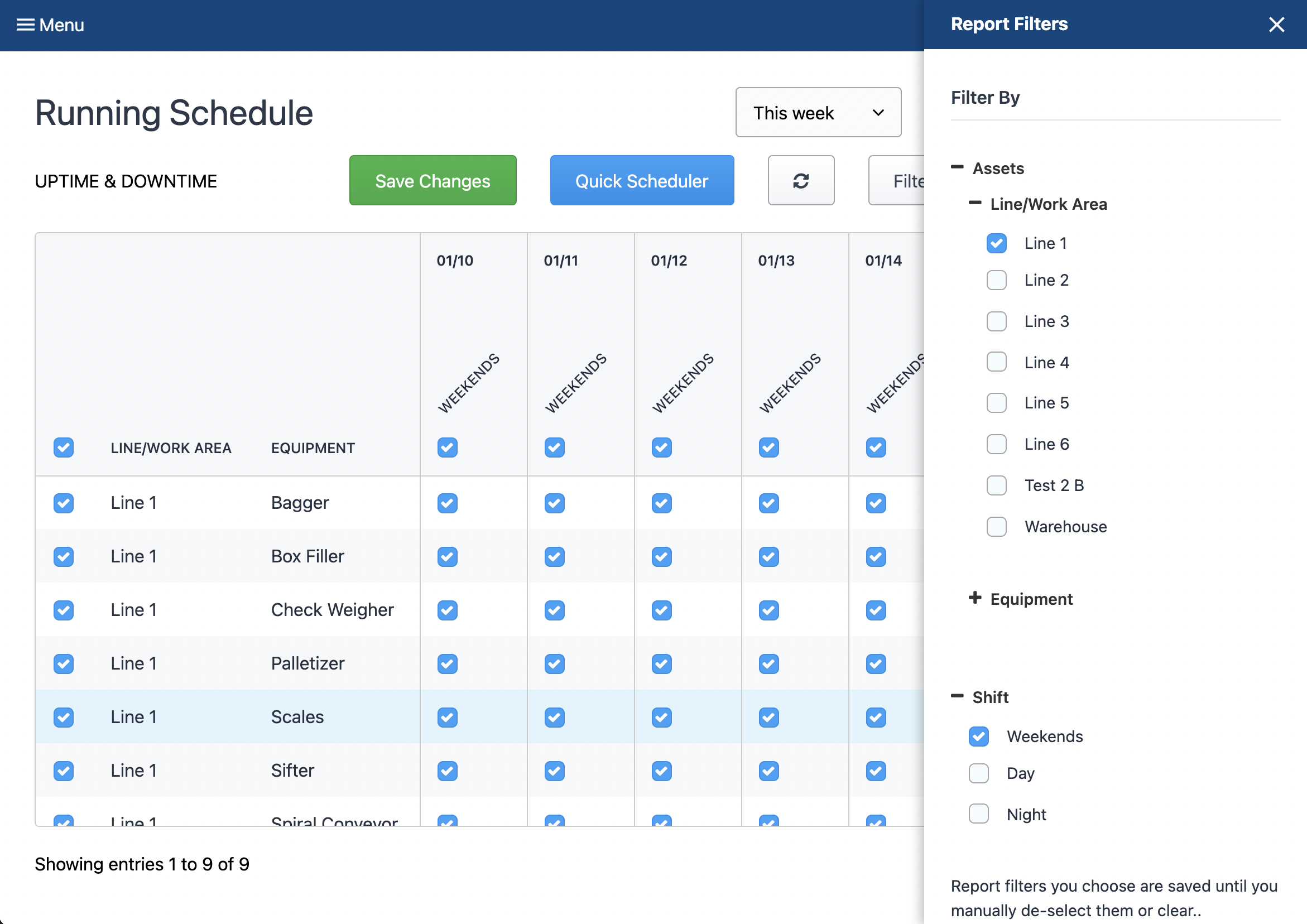

PAuse & REsume schedules

Add planned or unplanned downtime with a single click.

Downtime happens. That's why Weever added a number of tools to help our clients manage their inspection schedules to accommodate down time. Pause a single inspection, a machine or equipment, a line, a shift, or everything all at once.

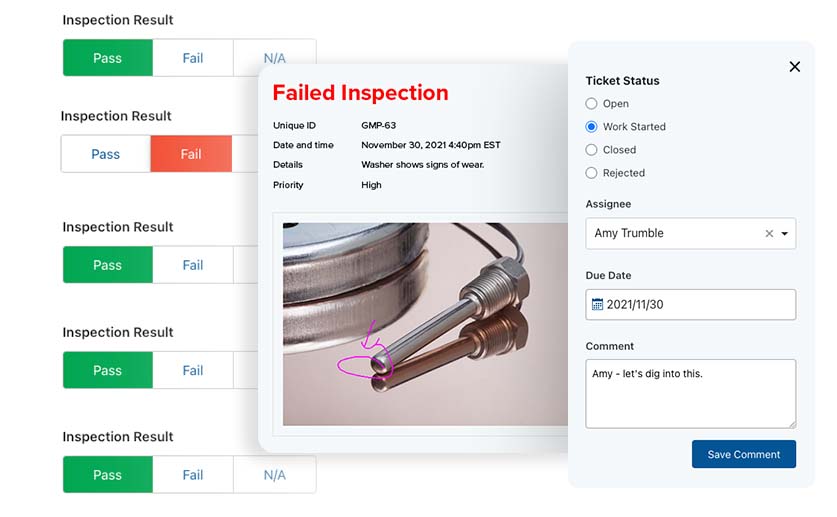

Receive alerts for failures.

“Failed” inspections automatically create a ticket for supervisor evaluation. Assign action items. Add due date. Move work forward.

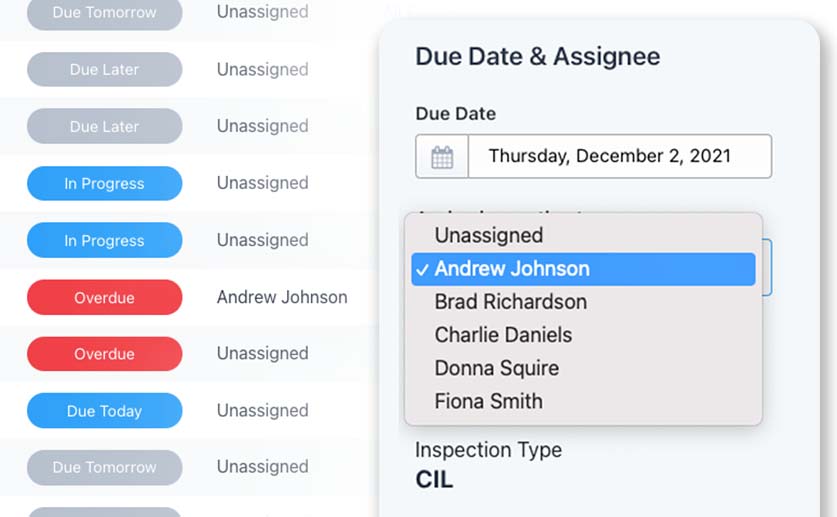

Ensure Accountability

Staff can be assigned inspections directly or they simply view what is due for the line they are working on.

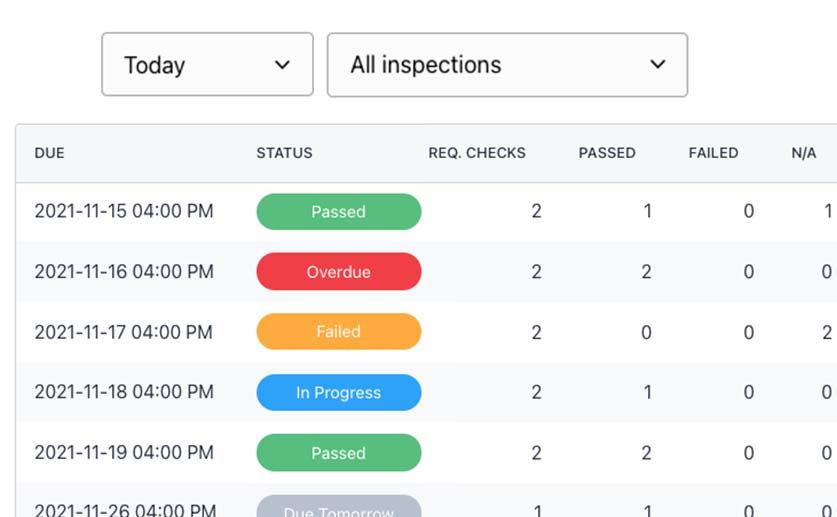

Understand everything at-a-glance.

Easily understand in real-time which inspections and audits have been completed, not started, overdue, passed, failed, etc.

Learn about the Platform.

Download the brochure to get all the details about how Weever works.

EXPLORE WEEVER SOLUTIONS in action

- All Solutions

- Compliance

- Continuous Improvement

- Maintenance

- Quality

- Safety

- Total Productive Maintenance

- Skills Development

- Warehouse

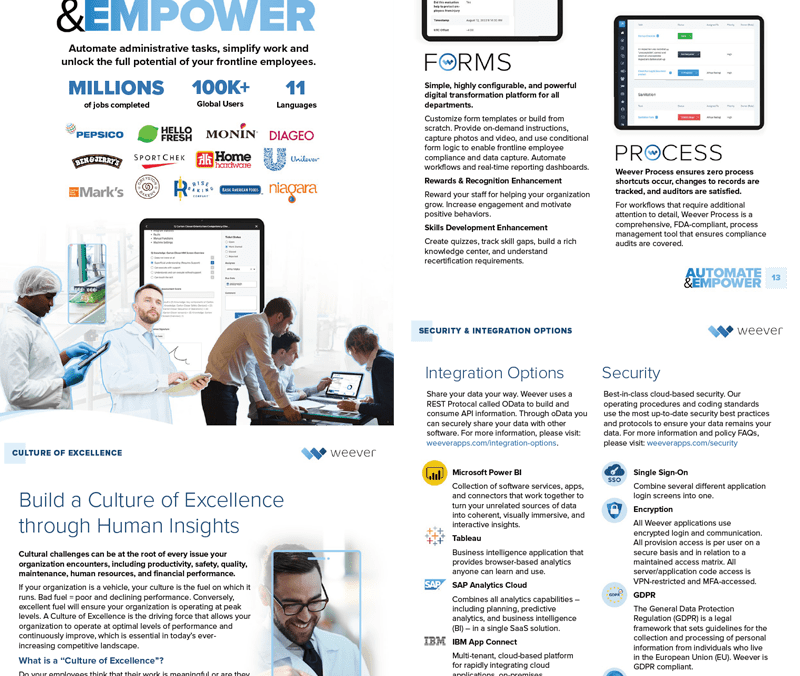

Fire Protection Equipment Inspections

Digitize fire protection inspections to ensure they are completed correctly.

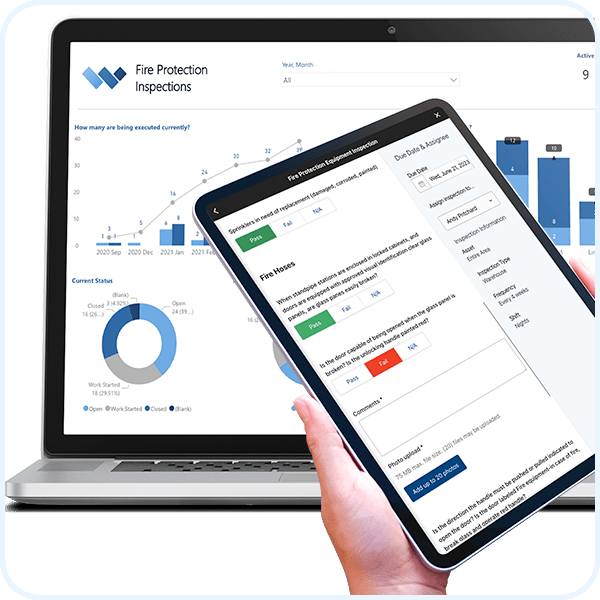

5S Workstation Optimization

Ensure workstations are optimized correctly and improvements are sustained by documenting Sort, Set in Order and Shine steps including photos and videos.

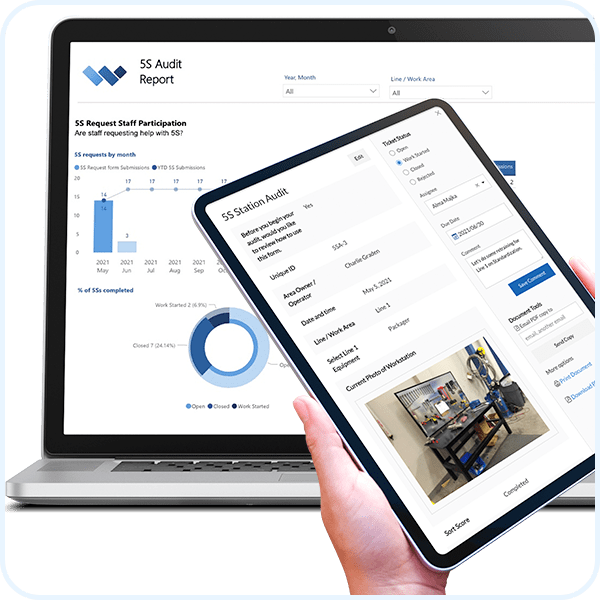

6S Lean: 5S + Safety

Ensure 6S Lean (5S + Safety) audits are completed correctly including photos or video capture.

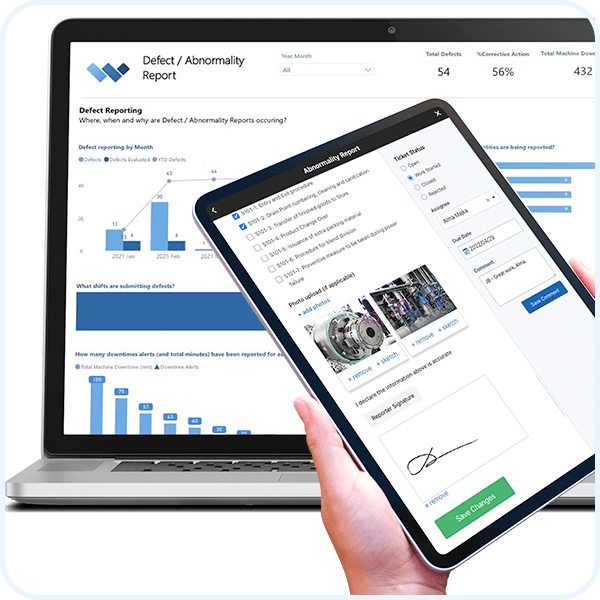

Abnormality Reporting

Make it easy for staff to report Process Abnormalities and for managers to initiate PDCA projects.