Warehouse Rack Inspections Reporting Dashboard

Do you have a question?

How do Warehouse Pallet Rack Inspections Work?

Warehouse Rack Inspections are required usually at least 2 times per year and also whenever modifications are made. Some customers execute them weekly. Inspectors evaluate the state of the framing, supports, alignment and guardrails, check for corrosion, and ensure appropriate signage is displayed. Most jurisdictions require rack inspections by law.

Why are Warehouse Pallet Rack Inspections Important?

- Enhance the safety of the work environment.

- Reduce liability.

- Save money and time associated with issues from racking defects.

Why Digitize Warehouse Rack Inspection?

Rack inspections can be complex. Using paper forms leaves too much up to chance. Digitization ensures scheduled inspections occur and provides more opportunities to guide and inform the inspector, increasing the likelihood of failures being detected and corrected.

- Reduce Errors - Digital features help to ensure forms are completed correctly every time.

- Ensure Compliance - Automate schedules and requirements to ensure inspections are executed correctly every time.

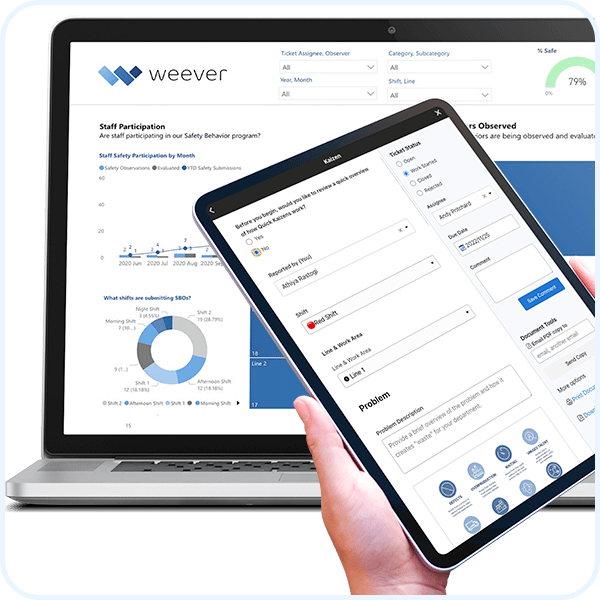

- Real-time Visibility - Managers can collaborate in real-time with inspectors to ensure issues are resolved quickly and correctly.

Learn more about Workflow Management

bandjlogo

Bell-logo-New

Canadian-Tire-Logo

Diageo-customer-logo

greyston-bakery-logo

hello-fresh-customer

marks-customer-logo

CSL_Limited_logo

monin-logo

Winland Food

Mars-logo-main

rise-baking-customer-logo

Rockwool-Customer-Logo-min

Sportcheck-customer-logo

unilever-customer-logo

walmart-logo-small

husqvarna-customer-logo

Ajinomoto_logo

Peet's_Coffee_logo

Royal-Canin-Logo

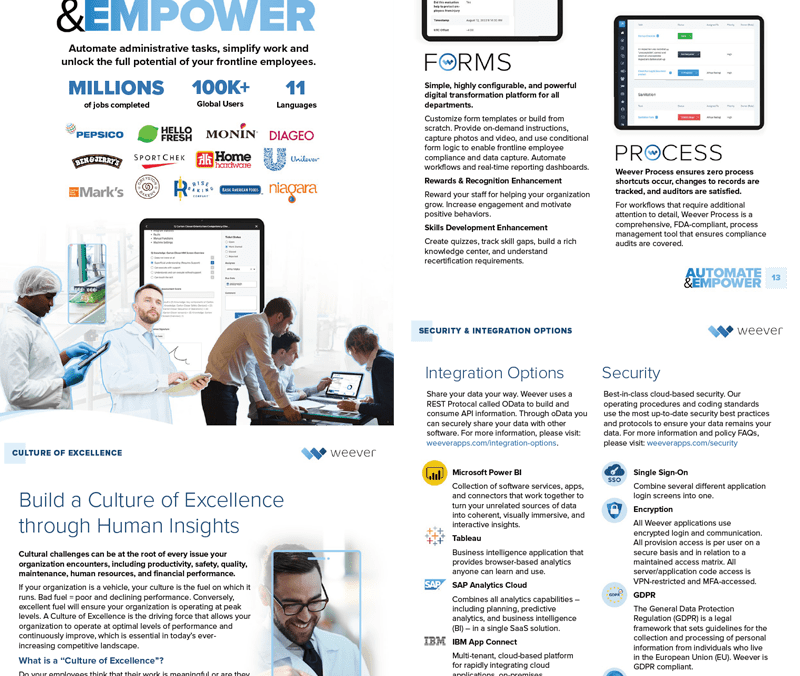

Learn about the Platform.

Download the brochure to get all the details about how Weever works.