Practical implementation guide to

Proactive Safety

for manufacturing and warehouses

Proactive Safety Programs

Everything you need to drive proactive safety at your facility.

- Proactively identify and mitigate safety risks.

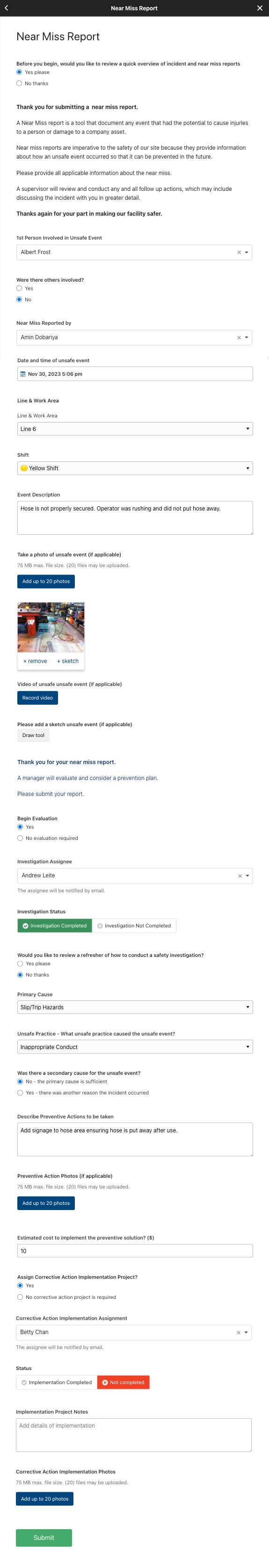

- Employees can report on safe behaviors, potential hazards, and near misses.

- Creating a culture of continuous improvement.

- Track trends, analyze data, and implement corrective actions to prevent future incidents.

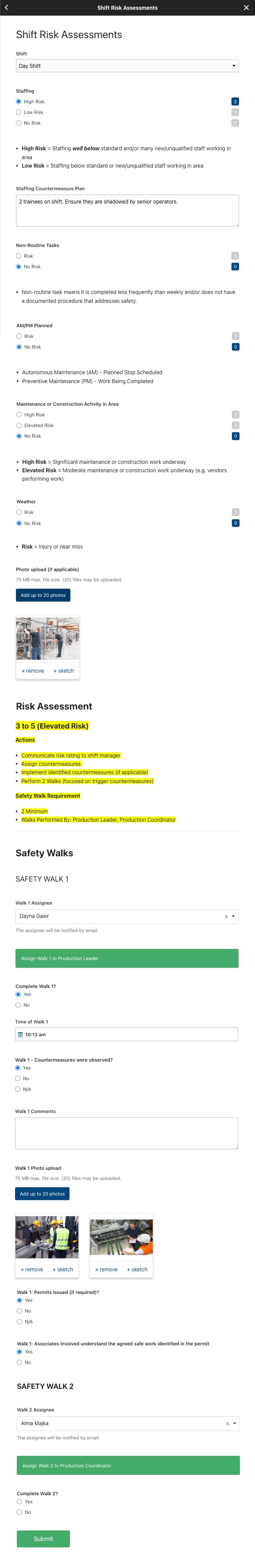

- Identify potential safety risks within the workplace

- Customizable templates and checklists

- Assess hazards, evaluate risk levels, and implement appropriate control measures

- Create a safer work environment and reduce the likelihood of accidents.

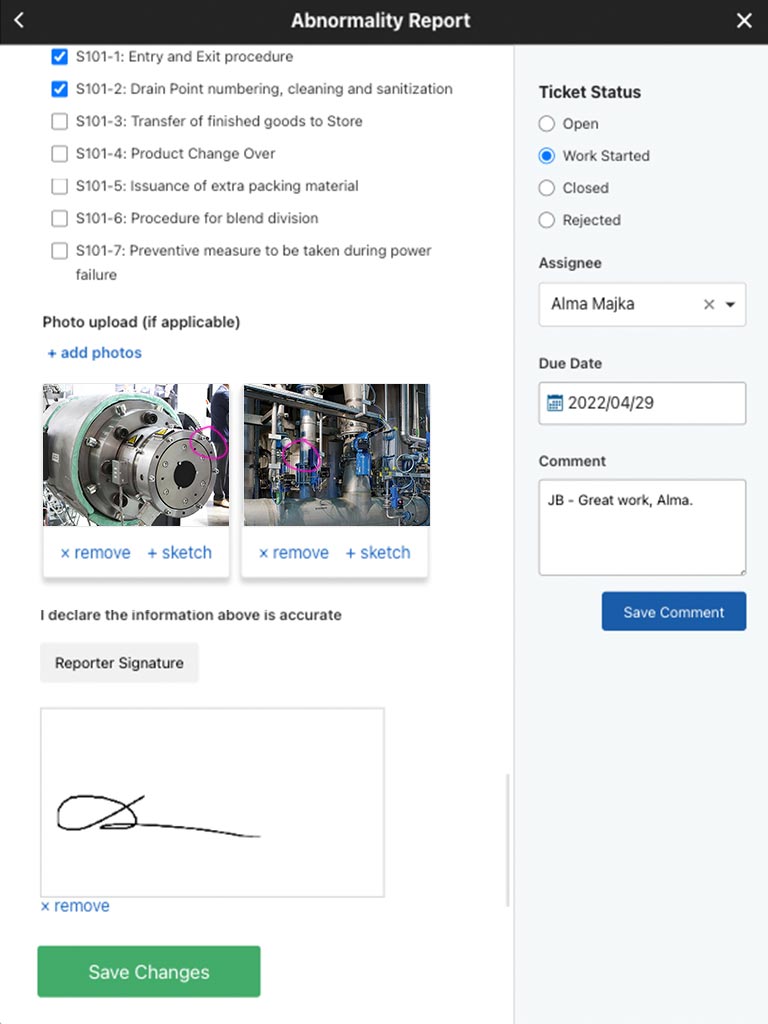

- Identify and address abnormal conditions or non-conformities swiftly.

- Report abnormalities such as equipment malfunctions, process deviations, or any other deviations from standard procedures.

- Ensure that potential safety hazards are promptly addressed, reducing the risk of accidents and injuries.

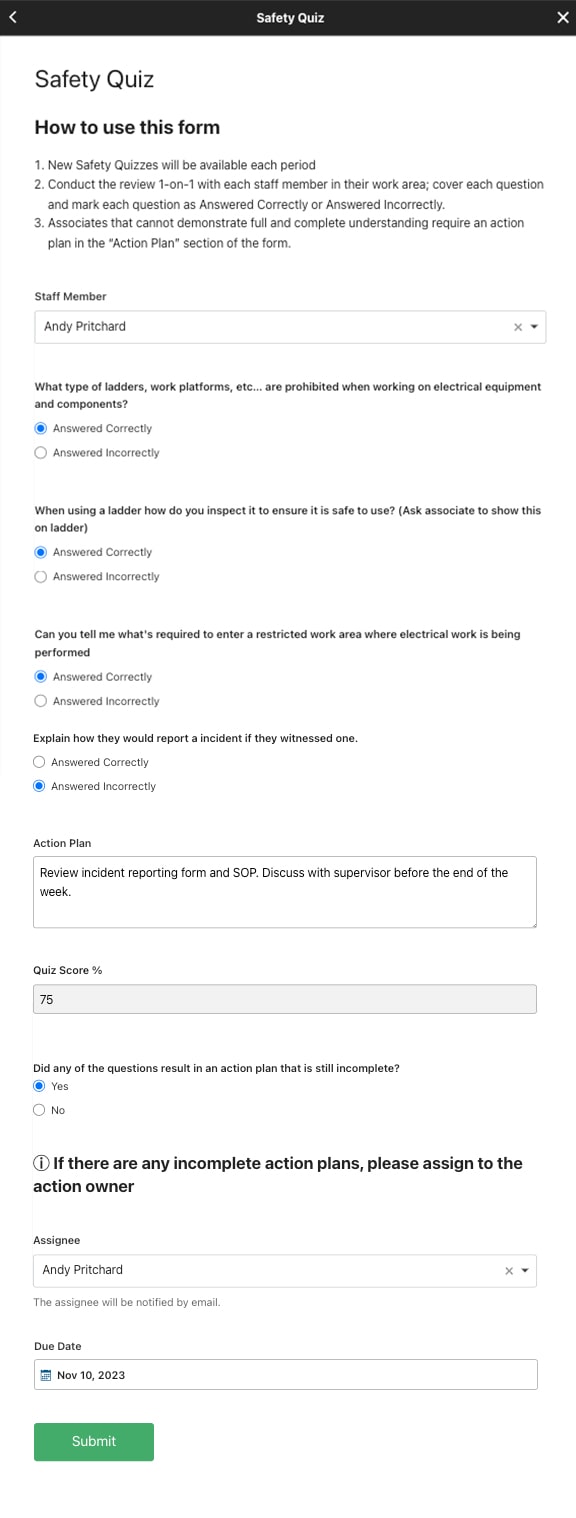

- Conduct monthly safety quizzes to engage with frontline employees and gather valuable insights.

- Foster a safety-focused culture, encourage employee participation, and enable continuous improvement.

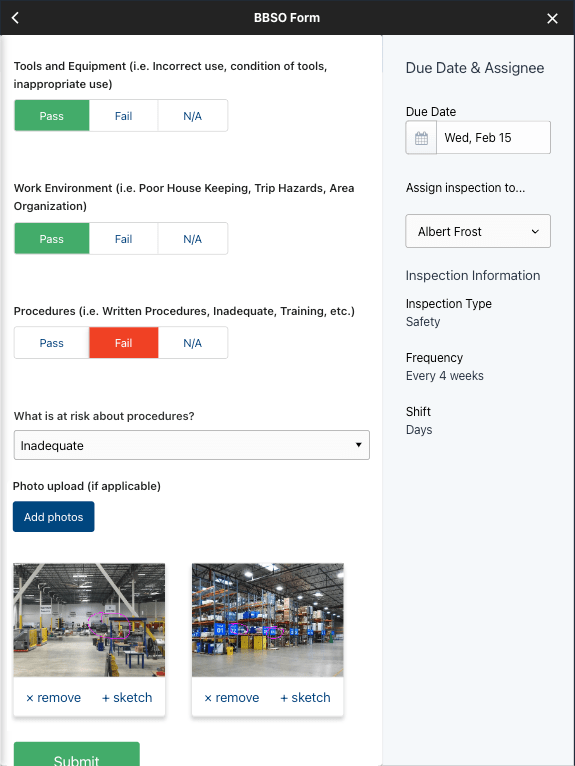

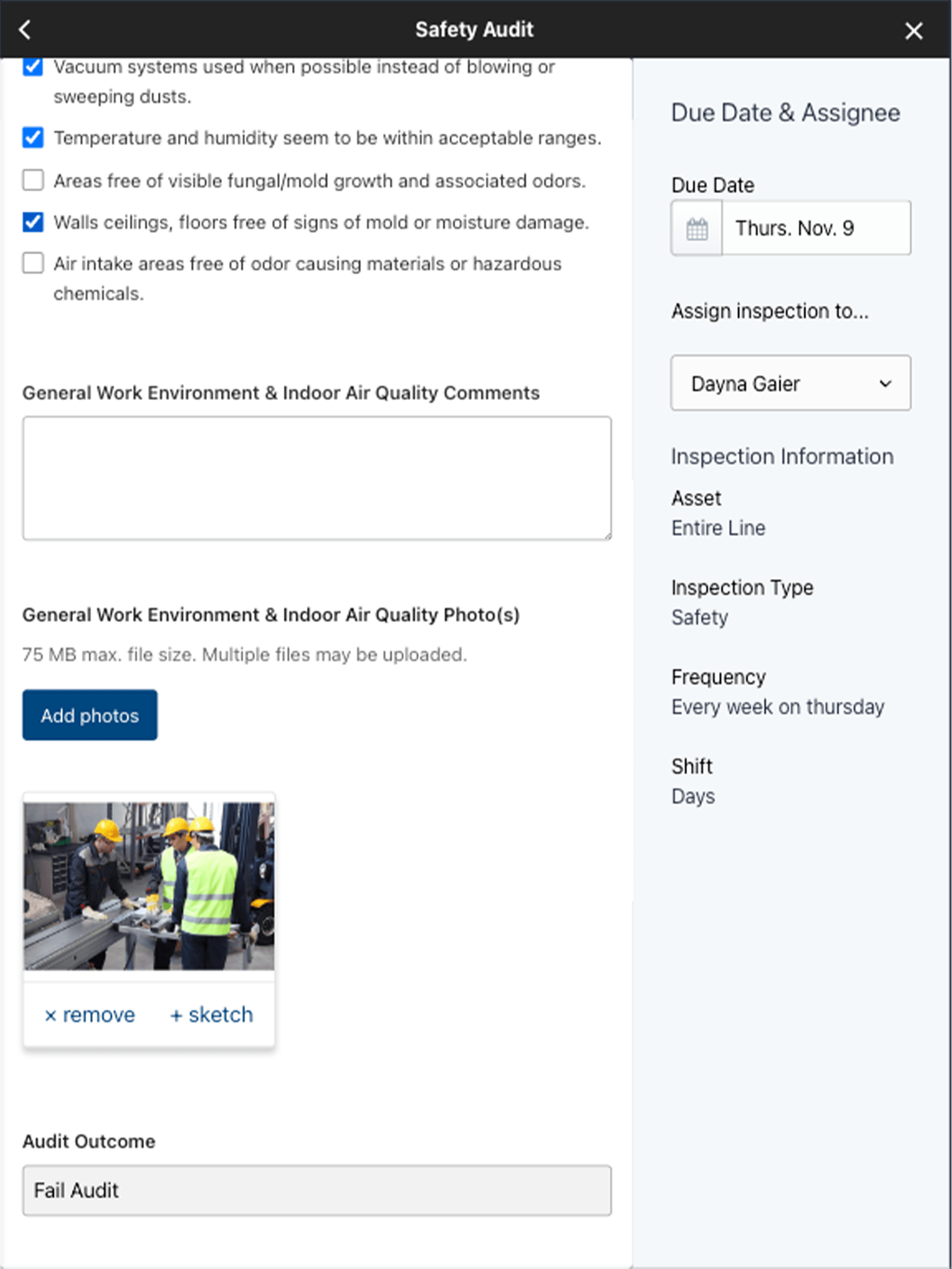

- Schedule and conduct regular inspections to ensure compliance with safety standards and regulations

- User-friendly interface for capturing inspection data, taking photos, and assigning corrective actions

- Identify and mitigate potential hazards, ultimately reducing the risk of accidents and injuries

- Identify and report safety risks without skipping a beat.

- Quickly review photos, videos and make evaluations.

- Create and assign action items and follow progress to completion.

- Keep all stakeholders in the loop so they understand the positive impact they are making.

“Having cloud-based forms on devices around the facility makes them so much more accessible, which makes it painless for operators to quickly provide a report.”

Johanna Velez, VP Quality Assurance

"Weever is really user friendly and will have a massive positive impact on our operations and training team."

Mel Cadle - Op Ex Lead Process Engineer

“It’s shifted our safety culture because now we are much more focused on what we should be looking at.”

Kody Crossen, Operations Manager of EHS

Marks

Diageo

Niagara Bottling

Walmart

PepsiCo logo

McDonald's

Unilever

Monin

Hello Fresh

Rise Baking

Rockwool

Canadian Tire

SportChek

Greyston Bakery

Bell

Husqvarna

Home Hardware