How Can Manufacturing Plants Create Efficient CIL Checklists Using Weever?

Learn how Weever helps manufacturing plants create efficient CIL checklists to streamline maintenance, reduce downtime, and improve overall equipment effectiveness.

In the manufacturing industry, equipment downtime can lead to significant financial losses, production delays, and reduced operational efficiency. Effective maintenance routines are essential to keeping machinery running smoothly, and this is where Cleaning, Inspection, and Lubrication (CIL) tasks play a crucial role. By implementing CIL checklists, manufacturing plants can ensure regular upkeep of their equipment, preventing breakdowns and enhancing overall equipment effectiveness (OEE).

However, managing these tasks manually can be time-consuming and prone to errors. Manufacturing plants can benefit greatly from digitizing their CIL checklists and automating task management through a platform like Weever. This not only streamlines the maintenance process but also provides valuable insights that can help optimize equipment performance over time. In this blog, we’ll explore how manufacturing plants can create efficient CIL checklists using Weever and how this can improve maintenance processes, reduce downtime, and increase productivity.

Simplifying CIL Checklist Creation with Weever

Creating and managing CIL checklists can be a daunting task, especially in large manufacturing plants with multiple pieces of equipment. Weever’s user-friendly platform makes it easy for teams to create digital CIL checklists and manage them efficiently, even without extensive technical expertise.

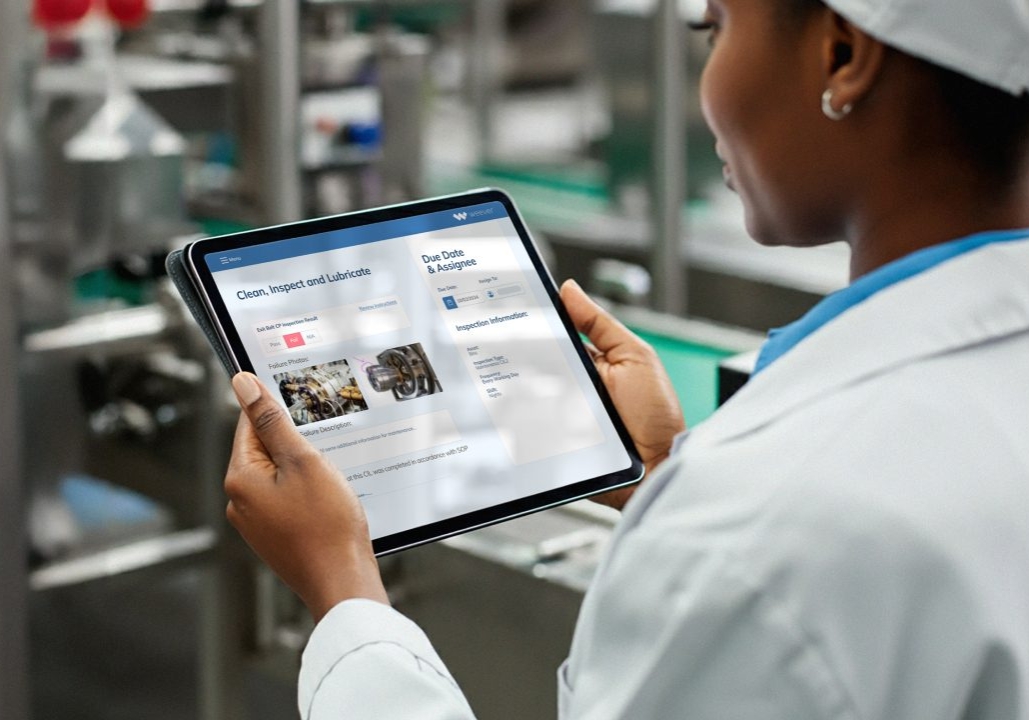

Intuitive Interface for Easy Checklist Management

Weever’s interface is designed to be simple and intuitive, allowing manufacturing teams to create CIL checklists quickly and easily. With just a few clicks, operators can set up tasks for cleaning, inspecting, and lubricating equipment, ensuring that all necessary maintenance procedures are covered. Operators can also access CIL standard operating procedures (SOPs) directly from the platform, making it easier for them to follow detailed steps without needing paper manuals or extra guidance.

Quick Access to CIL Tasks

Frontline worker maintenance is crucial to minimizing downtime and maintaining efficiency on the shop floor. With Weever, operators can access their assigned CIL tasks in real-time, allowing them to check off items on their CIL checklists as they go. Whether it's following lubrication schedules, inspecting machine components, or cleaning equipment surfaces, operators can complete tasks quickly and without interruption.

An Example from a Car Manufacturing Plant

A car manufacturing plant can use Weever to create CIL checklists for its assembly line machines, allowing operators to easily access their daily maintenance tasks. This ensures that cleaning standards are met, inspections are done on time, and lubrication schedules are followed consistently, improving machine longevity.

Streamlining CIL Task Management

Once CIL checklists are in place, keeping track of which tasks are completed and when the next maintenance is due can be a challenge, especially for decentralized maintenance teams. Weever solves this problem by automating workflows and generating action items that are directly tied to CIL checklists.

Automating Task Assignments

Weever automates the assignment of CIL tasks, ensuring that maintenance routines are followed regularly without manual oversight. Operators receive notifications when it’s time to perform cleaning, inspection, or lubrication tasks, ensuring that maintenance is carried out on schedule and no steps are missed. The automation of preventive maintenance by operators helps manufacturing plants maintain equipment reliability without requiring constant supervision.

Translating CIL Checklists into Action Items

Weever turns CIL checklist items into clear, actionable tasks for operators. For example, if an inspection reveals a worn-out component, the operator can automatically create a follow-up task for repair or replacement, preventing small issues from escalating into larger problems. This level of task automation helps manufacturing facilities maintain smooth operations and reduces the likelihood of costly breakdowns.

Data-Driven Maintenance Optimization

One of the biggest advantages of digitizing CIL checklists through Weever is the ability to track and analyze maintenance data over time. This helps plant managers gain valuable insights into how their equipment is performing and identify areas for improvement.

Tracking CIL Performance and Compliance

Weever provides real-time tracking of all CIL tasks, allowing managers to monitor whether cleaning standards, inspection routines, and lubrication schedules are being followed consistently. By tracking CIL with connected worker platforms, plant managers can see which tasks have been completed and which are still pending, ensuring full compliance with maintenance protocols.

Identifying Trends and Recurring Issues

By analyzing data collected from CIL checklists, Weever enables manufacturing plants to identify trends and recurring issues with specific equipment. For example, if a particular machine requires frequent lubrication, managers can adjust the lubrication schedule to improve performance and reduce wear. This kind of preventive maintenance by operators can greatly extend the lifespan of machinery.

Real-Time Reporting for Instant Visibility

Weever’s real-time reporting feature provides instant visibility into the status of CIL checklists and maintenance tasks. Plant managers can see whether critical tasks have been completed on time and ensure that all equipment is being maintained according to industry standards. This level of transparency helps manufacturing plants avoid compliance violations and keep production running smoothly.

An Example from a Manufacturer

A manufacturing facility uses Weever to track the completion of CIL checklists for its conveyor belts and sealing machines. By analyzing the data, the plant manager notices that the sealing machines need more frequent lubrication, leading to an adjustment in the lubrication schedule that reduces downtime and improves production efficiency.

Seamless Integration of Digital CIL Checklists

Implementing digital CIL checklists in a manufacturing plant may seem like a complex task, but Weever’s tailored rollout methodology makes the transition seamless. The platform is designed to be integrated gradually, allowing teams to adopt the new system without disrupting daily operations.

Phased Rollout for Minimal Disruption

Weever’s phased rollout process ensures that manufacturing teams can transition to digital CIL checklists at their own pace. This prevents disruptions to production schedules and ensures that operators can gradually get accustomed to the new system. The platform can be implemented one department or machine at a time, making the transition smooth and manageable.

Comprehensive Training and Support

Weever offers comprehensive CIL training for operators to ensure they can effectively use the platform to manage their maintenance tasks. Operators are trained on how to follow digitized CIL instructions, use visual controls for CIL, and track their progress through the platform. This training helps standardize CIL practices across the plant, ensuring that all maintenance tasks are performed consistently and according to best practices.

Weever’s Role in Creating Efficient CIL Checklists for Manufacturing Plants

Efficient equipment maintenance is crucial to minimizing downtime and maintaining production quality. By using Weever to create and manage digital CIL checklists, manufacturing plants can ensure that cleaning, inspection, and lubrication tasks are completed consistently and on time. The platform’s ease of use, automated workflows, and real-time reporting capabilities provide plant managers with full visibility into their maintenance routines, helping them optimize performance and improve overall equipment effectiveness.

Whether it’s ensuring that cleaning standards are met in a food production facility or maintaining lubrication schedules in a car manufacturing plant, Weever provides the tools needed to streamline CIL practices, reduce downtime, and extend equipment life. For manufacturing plants looking to improve their maintenance processes, Weever’s configurable solution is the ideal platform to drive efficiency and ensure that equipment is always performing at its best.

Contact us today to book a demo!

Discover how Weever streamlines CIL checklist creation for manufacturing efficiency.

Discover how Weever streamlines CIL checklist creation for manufacturing efficiency.

Continue Reading

"Having cloud-based forms on devices around the facility makes them so much more accessible, which makes it painless for operators to quickly provide a report."

Johanna Velez, VP Quality Assurance

"Weever is really user friendly and will have a massive positive impact on our operations and training team."

Mel Cadle - Op Ex Lead Process Engineer

"It's shifted our safety culture because now we are much more focused on what we should be looking at."

Kody Crossen, Operations Manager of EHS