Optimizing Lubrication Schedules with Weever: Improving Machine Longevity

Optimize lubrication schedules, enhance machine longevity, and streamline maintenance with Weever's automated tools, real-time insights, and seamless integration.

In manufacturing, equipment reliability is paramount to sustaining operational efficiency. A critical component of this reliability is the consistent and timely application of lubrication. Overlooking a lubrication task can result in costly equipment breakdowns, significant downtime, and reduced productivity.

Weever software offers an optimized approach to managing lubrication schedules, empowering operators to effectively oversee and execute these tasks. This post delves into how Weever facilitates the maintenance of consistent lubrication schedules to prolong equipment life in manufacturing environments.

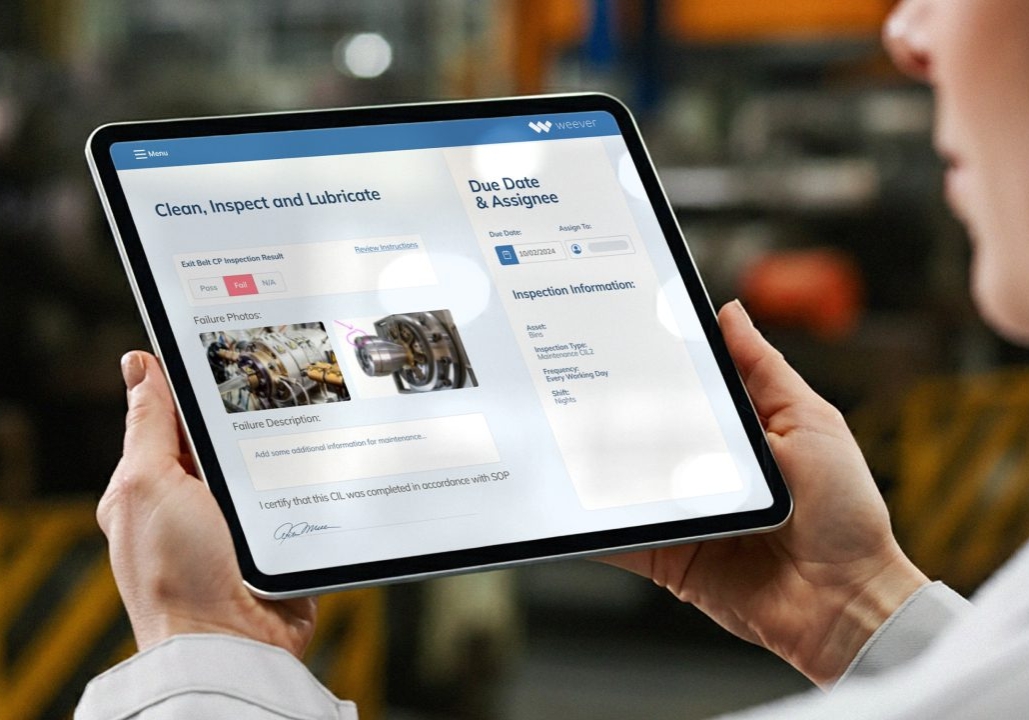

Weever's Intuitive Platform Simplifies Task Management

Weever's user-friendly platform enables operators to effortlessly manage lubrication schedules. This minimizes the risk of overlooked tasks and ensures consistent application across the manufacturing floor.

Streamlined Maintenance for Manufacturing Efficiency

In bustling manufacturing settings, operators often juggle multiple maintenance responsibilities. Weever's straightforward interfaces allow operators to swiftly check off lubrication tasks amidst busy production cycles. For instance, operators at a manufacturing plant might use Weever to regularly prompt maintenance reminders for CNC machines, thereby reducing downtime due to wear or friction.

Automated Reminders and Clear Action Items Keep Operations Smooth

Weever automates the scheduling and assignment of lubrication tasks, providing operators with timely reminders and clear directives. This ensures that maintenance is performed regularly and without interruption. For example, a packaging factory might utilize Weever to schedule lubrication for filling machines based on usage, optimizing task timing to prevent machine stoppages.

Data-Driven Insights Foster Proactive Maintenance Adjustments

Weever tracks lubrication performance data, offering valuable insights that help managers tailor maintenance schedules to better suit machine usage patterns and enhance longevity. For instance, a heavy machinery manufacturer could adjust lubrication frequencies based on real-time data, improving both machine performance and lifespan.

Seamless Integration with Existing Maintenance Workflows

Weever's tailored rollout process ensures that its lubrication management system can be seamlessly integrated into existing operations without disrupting ongoing activities. This might involve phased implementations, where a manufacturing team gradually adopts Weever, starting with critical equipment and expanding as familiarity with the platform increases.

Comprehensive Solution for Optimized Lubrication Management

By simplifying lubrication management, automating essential tasks, and providing actionable insights, Weever aids manufacturers in maintaining their equipment more effectively, thus extending its operational life. With tools that are easy to use, coupled with automated workflows and real-time reporting, Weever ensures consistent and timely lubrication, helping to mitigate downtime, avert equipment failures, and boost overall operational efficiency.

For manufacturers aiming to refine their lubrication practices and enhance equipment longevity, Weever offers an ideal solution.

Ready to enhance your manufacturing operations? Schedule a demo with Weever today and see how our lubrication management solutions can extend the life of your machinery and boost your operational efficiency. Don't miss out-optimize your maintenance practices now!

Ready to enhance your manufacturing operations? See how our lubrication management solutions can extend the life of your machinery and boost your operational efficiency.

Ready to enhance your manufacturing operations? See how our lubrication management solutions can extend the life of your machinery and boost your operational efficiency.

Continue Reading

"Having cloud-based forms on devices around the facility makes them so much more accessible, which makes it painless for operators to quickly provide a report."

Johanna Velez, VP Quality Assurance

"Weever is really user friendly and will have a massive positive impact on our operations and training team."

Mel Cadle - Op Ex Lead Process Engineer

"It's shifted our safety culture because now we are much more focused on what we should be looking at."

Kody Crossen, Operations Manager of EHS