How Walmart Utilizes Weever to Drive Proactive Safety

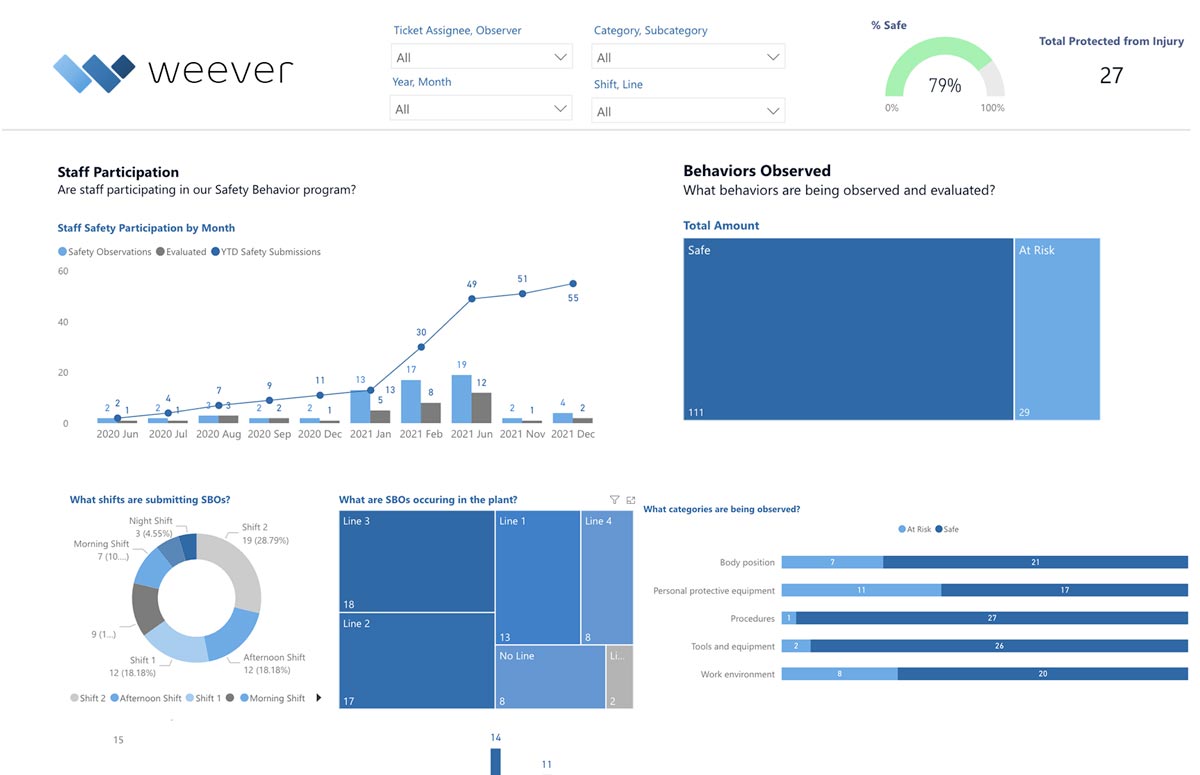

Distribution Center uses Safety Observations to be 60% to 70% more proactive and stop incidents before they occur.

weever case studies

case study highlights

- Walmart used Weever to become 60% to 70% more "proactive".

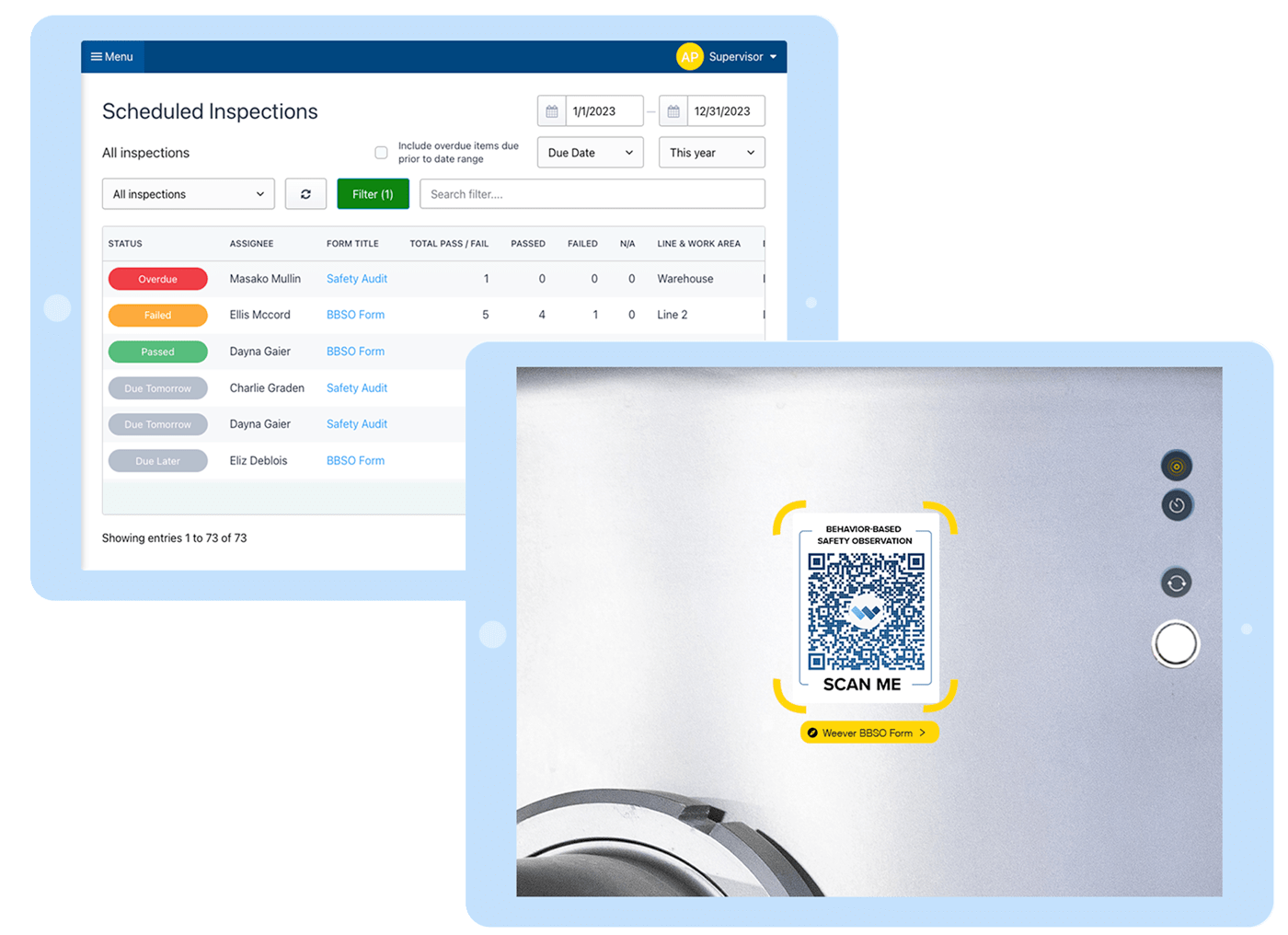

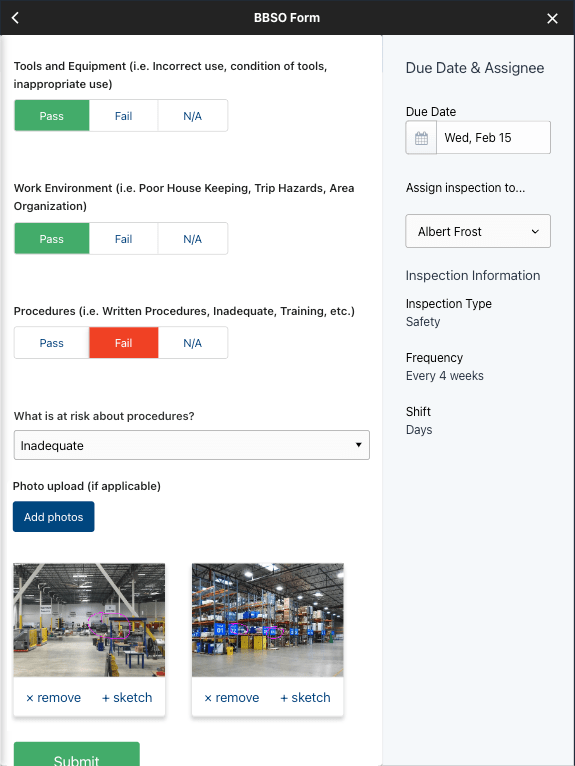

- Successful implementation of Weever's BBSO template resulted in a significant surge in safety observations within Walmart's Distribution Center.

- Proactive engagement and participation from supervisors, facilitated by the platform's adaptability, led to the quick adoption of the BBSO program.

- Innovative use of QR codes on racks facilitated easy access to BBSO forms, contributing to faster adoption rates.

- Swift updates and widespread acceptance by the operations team showcased Weever's effectiveness in streamlining processes.

In an insightful customer story video, Kody Crossen, Operations Manager EHS for Walmart Distribution Center (DC) in Pennsylvania, reveals the invaluable role of Behavior-Based Safety Observations (BBSO) in preventing safety incidents. Discover why Kody has found Weever, an innovative operations management software platform specializing in Food and CPG manufacturing, to be an indispensable tool for managing Walmart's BBSO program.

Enhancing Safety Observations with Weever

Seeking a comprehensive software solution for safety observation management, Kody turned to Weever. Dissatisfied with their existing system that merely checked off completed observations, Kody recognized the need for a platform that could offer intelligent insights to understand trends and proactively prevent incidents.

“We wanted to put our foot forward at being proactive and looking at various trends in the multitude of different procedures we have going on 24/7.”

Kody Crossen, Operations Manager of EHS, Walmart

Interested in learning more about Weever's Proactive Safety Solution?

Building a Positive Safety Culture with Weever

Kody appreciates that Weever enables the recognition of associates who consistently demonstrate safe behaviors. Positive reinforcement plays a crucial role in fostering a robust safety culture. Furthermore, Kody believes Weever outshines other platforms by guiding supervisors through the process, ensuring successful outcomes.

“It’s shifted our safety culture because now we are much more focused on what we should be looking at. And it also allows the associates to understand what we are looking for so it's not as arbitrary as it once was. It’s creating a lot more conversation and I think it's making the associates much more mindful of their actions.”

Kody Crossen, Operations Manager of EHS, Walmart

Expanding the Reach of Weever

Impressed with the benefits realized through Weever's implementation, Kody plans to extend its usage to additional safety applications within his Distribution Center.

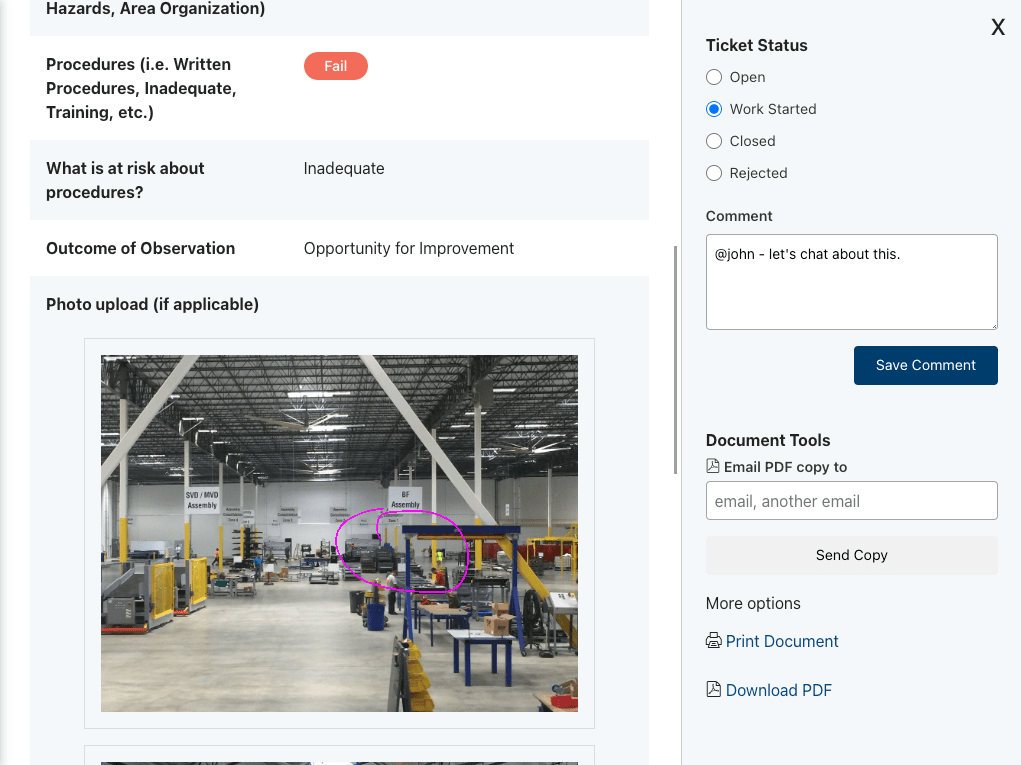

Behavior-Based Safety Observations

Everything you need to get it done.

Customizable Templates

Dashboard Reporting

Automated Workflows

Schedule Management

Real-time Visibility

On-Demand Instructions

bandjlogo

Bell-logo-New

Canadian-Tire-Logo

Diageo-customer-logo

greyston-bakery-logo

hello-fresh-customer

marks-customer-logo

CSL_Limited_logo

monin-logo

Winland Food

Mars-logo-main

rise-baking-customer-logo

Rockwool-Customer-Logo-min

Sportcheck-customer-logo

unilever-customer-logo

walmart-logo-small

husqvarna-customer-logo

Ajinomoto_logo

Peet's_Coffee_logo

Royal-Canin-Logo

Digital DATA CAPTURE

Get it done correctly every time.

WORKFLOW AUTOMATION

Evaluate and improve.

REAL-TIME REPORTING

Automate Business Intelligence.

100K+

Global Users

MILLIONS

of jobs completed

11

Languages

"The Weever suite is easy to understand and the support from the team has been amazing!"

Laura Curtis - Operational System and Process Manager, HelloFresh

"Weever saves me time, makes data visible and drives results!"

DENAIR M. - Training Manager

"Weever has changed how I run our business."

Ingrid K. - Plant Director

"Weever is extremely easy to use and simple to manage."

NICKI V - CI Engineer

"Weever gives me immediate insights into my business."

COLIN H. - Operational Excellence Manager

"The Weever team are extremely helpful and are always on hand to help with any questions or queries we may have."

Mel Cadle - Op Ex Lead Process Engineer, HelloFresh