How Can We Enhance Warehouse Productivity Through Autonomous Maintenance with Weever?

Boost warehouse productivity with Weever's Autonomous Maintenance tools, streamlining processes and reducing downtime effectively.

Warehouse productivity optimization is of the utmost importance in the modern, fast-paced industrial world. The ability to keep operations running smoothly while minimizing downtime is key to maintaining competitive advantages.

One strategy that has proven effective in achieving these goals is Autonomous Maintenance (AM). By empowering employees to take responsibility for the routine maintenance of their equipment, AM reduces the reliance on specialized maintenance staff, thus streamlining operations. However, the success of AM depends heavily on the tools used to implement and manage it. This is where Weever comes into play, offering an integrated solution that enhances warehouse productivity through effective AM.

User-Centric Design

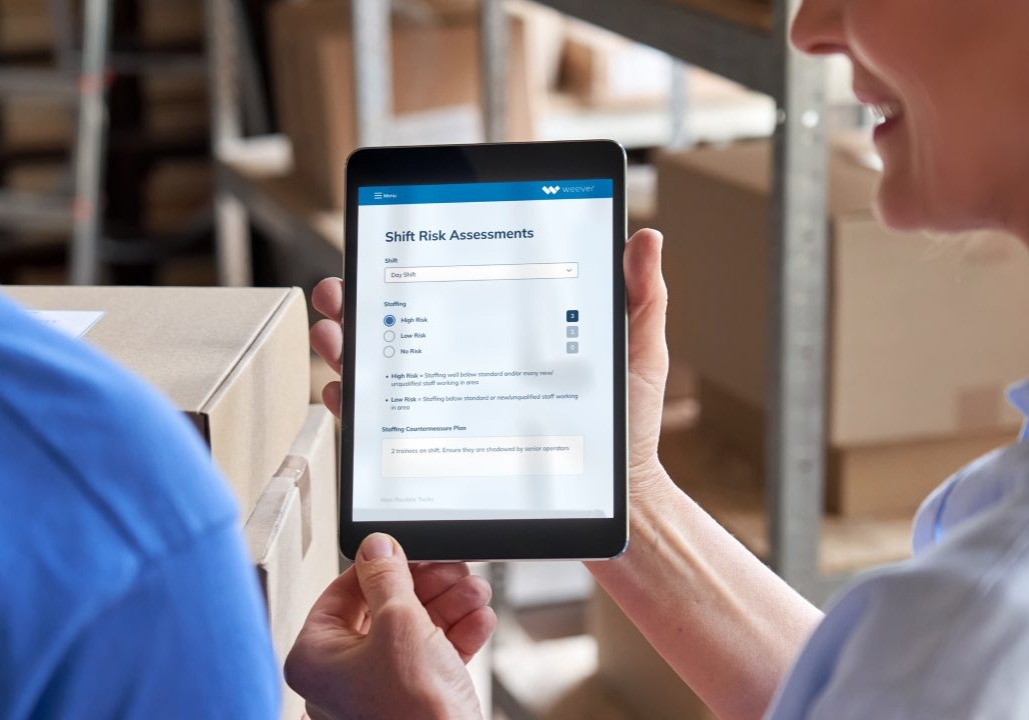

Adopting a new maintenance strategy can often seem daunting, especially when it involves a shift in responsibilities and the use of new technology. However, Weever's intuitive interface makes this transition seamless. The platform is designed with user experience in mind, ensuring that even those with limited technical skills can easily navigate and utilize its features.

Weever simplifies the adoption of AM by providing a clear and straightforward workflow for warehouse teams. This user-friendly design reduces the learning curve and limits the need for extensive training, allowing teams to focus more on their core tasks and less on figuring out how to use the software. The result is a faster and smoother implementation of AM practices, with minimal disruption to ongoing operations.

Consistent Workflow Automation

One of the most significant challenges in maintaining warehouse productivity is ensuring that maintenance tasks are completed systematically and efficiently. Weever addresses this challenge by automating maintenance workflows and assigning action items, ensuring that all necessary tasks are performed in a timely and organized manner.

With Weever, each maintenance task can be scheduled, tracked, and monitored, ensuring that nothing falls through the cracks. Automated reminders and notifications help keep teams on track, while action items can be assigned to specific individuals or groups, ensuring accountability and clarity in task execution. By reducing manual oversight and streamlining processes, Weever helps minimize downtime and enhance overall productivity in the warehouse.

Maintenance Performance Insights

Understanding the performance of maintenance activities is crucial for continuous improvement. Weever provides warehouses with the tools to gather and analyze data from all maintenance activities, offering valuable insights and identifying trends that can help optimize operations and reduce costs.

By leveraging Weever's analytics capabilities, warehouse managers can gain a deeper understanding of how equipment is performing and where improvements can be made. This data-driven approach allows for informed decision-making, enabling teams to identify potential issues before they become critical, thus avoiding costly downtime. Moreover, the ability to track and analyze trends over time helps in fine-tuning maintenance schedules and practices, leading to more efficient operations and prolonged equipment life.

Continuous Reporting

In the dynamic environment of a warehouse, having access to real-time information is essential. Weever's real-time reporting capabilities ensure that warehouse managers have up-to-date information on the status of maintenance tasks, allowing for immediate action when necessary.

With Weever, all maintenance activities are recorded and reported in real-time, providing a clear overview of what has been done and what still needs attention. This level of transparency enables managers to monitor progress continuously, address issues promptly, and make data-backed decisions that contribute to the overall efficiency of the warehouse. The ability to access real-time reports from any device also adds a layer of convenience, ensuring that the information is always available when needed.

Progressive Rollout Approach

Implementing AM across a warehouse is not just about adopting new practices; it also involves ensuring that these practices are consistently applied across all teams. Weever supports a structured rollout methodology, providing configurable templates and best practice guidelines to ensure a smooth and consistent adoption.

Weever's rollout methodology is designed to be flexible, catering to the unique needs and workflows of each warehouse. Whether rolling out AM practices in phases or across different teams simultaneously, Weever offers the tools needed to manage the process effectively. The platform also provides training materials and support, helping teams get up to speed quickly and ensuring that everyone is on the same page. This structured approach to implementation minimizes disruptions and ensures that AM practices are embedded effectively within the organization.

Enhancing Warehouse Productivity with Autonomous Maintenance: A Strategic Move

The success of AM largely depends on the tools used to implement and manage it. Weever offers a comprehensive solution that not only simplifies the adoption of AM practices but also enhances them through automation, real-time reporting, and data-driven insights.

By providing an intuitive, user-friendly platform, automating critical maintenance workflows, delivering actionable insights, and supporting a structured rollout, Weever empowers warehouses to implement AM effectively. This not only boosts productivity but also ensures that operations run smoothly, efficiently, and with minimal disruption.

For warehouses looking to enhance their productivity through Autonomous Maintenance, Weever offers the tools and support needed to make it happen. By leveraging Weever's capabilities, warehouses can streamline their maintenance processes, optimize operations, and ultimately achieve greater efficiency and productivity.

Ready to take your warehouse productivity to the next level with Autonomous Maintenance? Connect with us today and discover how Weever can streamline your operations and keep your business running smoothly. Let's start optimizing together!

Transform Your Warehouse Efficiency with Weever-Discover the Power of Autonomous Maintenance Today!

Transform Your Warehouse Efficiency with Weever-Discover the Power of Autonomous Maintenance Today!

Continue Reading

"Having cloud-based forms on devices around the facility makes them so much more accessible, which makes it painless for operators to quickly provide a report."

Johanna Velez, VP Quality Assurance

"Weever is really user friendly and will have a massive positive impact on our operations and training team."

Mel Cadle - Op Ex Lead Process Engineer

"It's shifted our safety culture because now we are much more focused on what we should be looking at."

Kody Crossen, Operations Manager of EHS