Welcome to the Digitization Mavericks Blog.

Digitization Mavericks is dedicated to helping manufacturing leaders drive efficiency, quality, and safety through digital transformation.

Topics covered include 5S Auditing, Operational Excellence, proactive safety, quality management, and sanitation. The articles provide actionable insights and best practices to help you get the most out of your factory floor.

Search our blog

- All Articles

- 5S Auditing

- AM

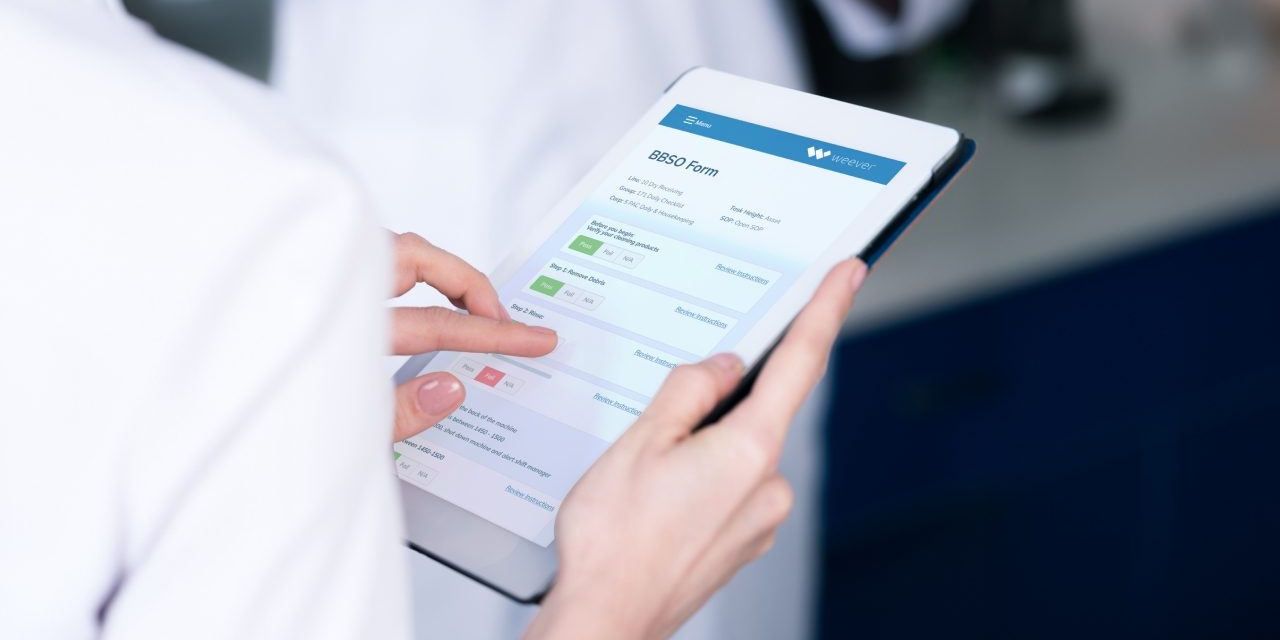

- Behavior Based Safety Observations

- Best Practices

- Digitization Mavericks

- Digitization Mavericks Podcast

- Employee Engagement

- Maintenance Management

- Operational Excellence

- Proactive Safety

- Production Management

- Quality Management

- Safety Management

- Sanitation Management

- Webinars

Exploring Autonomous Maintenance: Definition and Benefits

Uncover autonomous maintenance meaning and benefits. Learn how this approach boosts efficiency and reduces downtime for your organization.

Factory Wi-Fi Setup

REMOTE FACTORY MANAGEMENT The recent global Covid-19 pandemic has awoken the world to the need…

FDA Regulated Software Validation Process

FDA requires software vendors to add features to their software to ensure data integrity and…

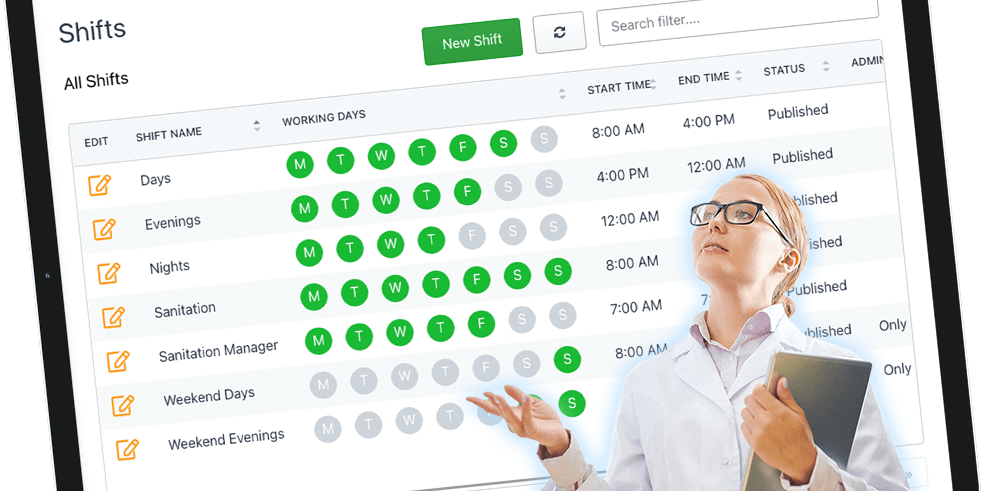

Filter your Skills Matrix Report by Shift, Role and Course

Skills Matrix Update The Training Manager Skills Matrix report has been updated to allow administrators…

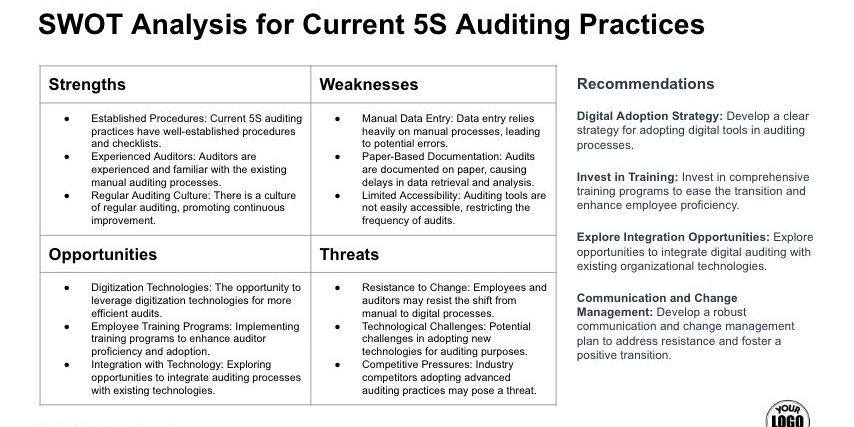

Free 5S Audit Digitization Presentation Template

Download this free Powerpoint (.pptx) template that includes a project summary, goals, KPIs, SWOT analysis, implementation plan and ROI calculations.

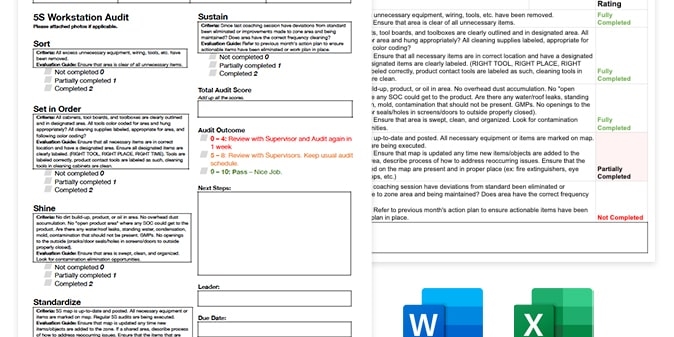

Free 5S Audit Form Templates

Download a free 5S Audit Spreadsheet template you can adapt to your unique requirements.

Free BBSO Poster

Free Behavior-Based Safety Observations Poster Download the Free BBSO Poster Promote the cycle of Behavior-Based…

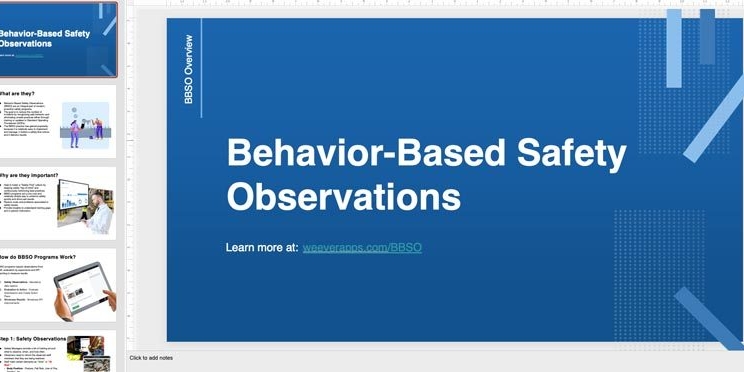

Free Behavior-Based Safety Observation (BBSO) Training PowerPoint Presentation .pptx

Free Behavior-Based Safety Observation Training Presentation Download the Free BBSO Training Presentation MS PowerPoint .pptx…

Gemba Walk Best Practices

Gemba Walks are an excellent tool used by successful organizations worldwide to optimize continuous improvement efforts. If you are just introducing Gemba Walks to your operations, or you are looking to take them to the next level, here are some tips that might help.

GMP Operational Audit Schedule for a Food Company

GMP Operational Audit Schedule for a Food Company Andy Pritchard | Dec 7, 2021 |…

How a Configurable Program Template Can Transform Your Manufacturing Operations

Proactive safety is about preventing incidents before they occur. What are some simple and practical steps you can take to be more proactive now?

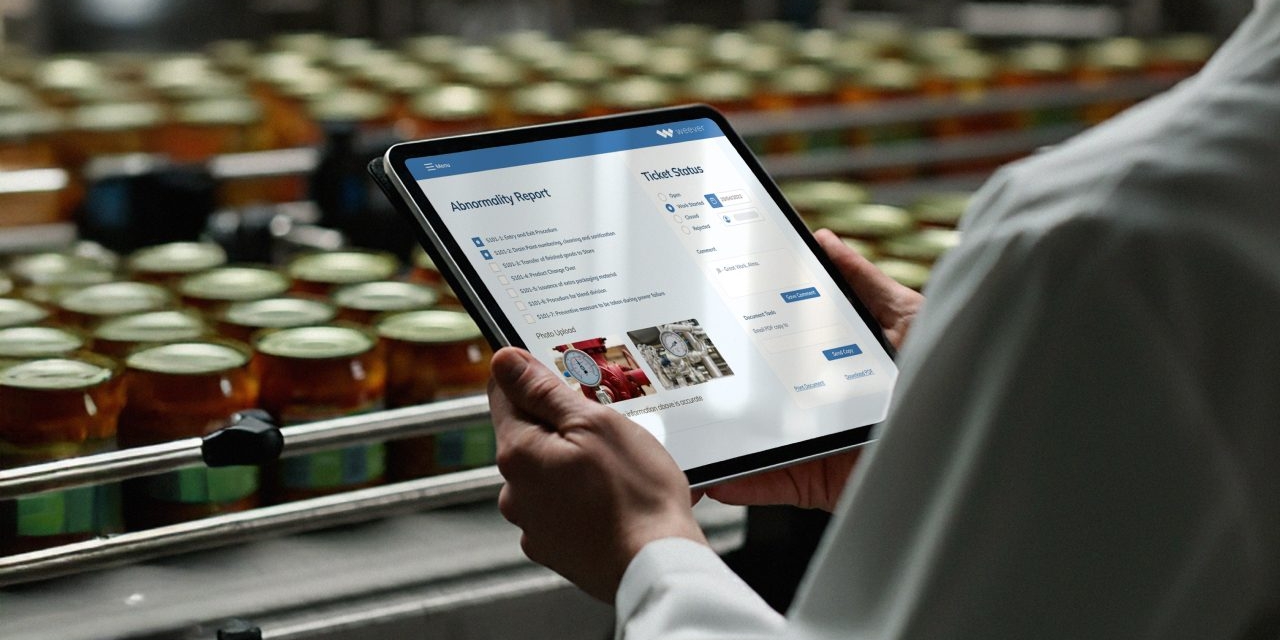

How a Smart Sanitation Schedule Transforms Food Manufacturing

How a Smart Sanitation Schedule Transforms Food Manufacturing Explore how Weever’s configurable MSS boosts food…

How Adient Streamlined Their 5S Auditing Process

Discover why Kody has found Weever, an innovative operations management software platform specializing in Food and CPG manufacturing, to be an indispensable tool for managing Walmart’s BBSO program.

How Autonomous Maintenance Programs Work

Deciding that you’d like to implement Autonomous Maintenance in your plant is a great first step towards promoting a more efficient and profitable plant. Now you’re faced with the real challenge – how to begin?

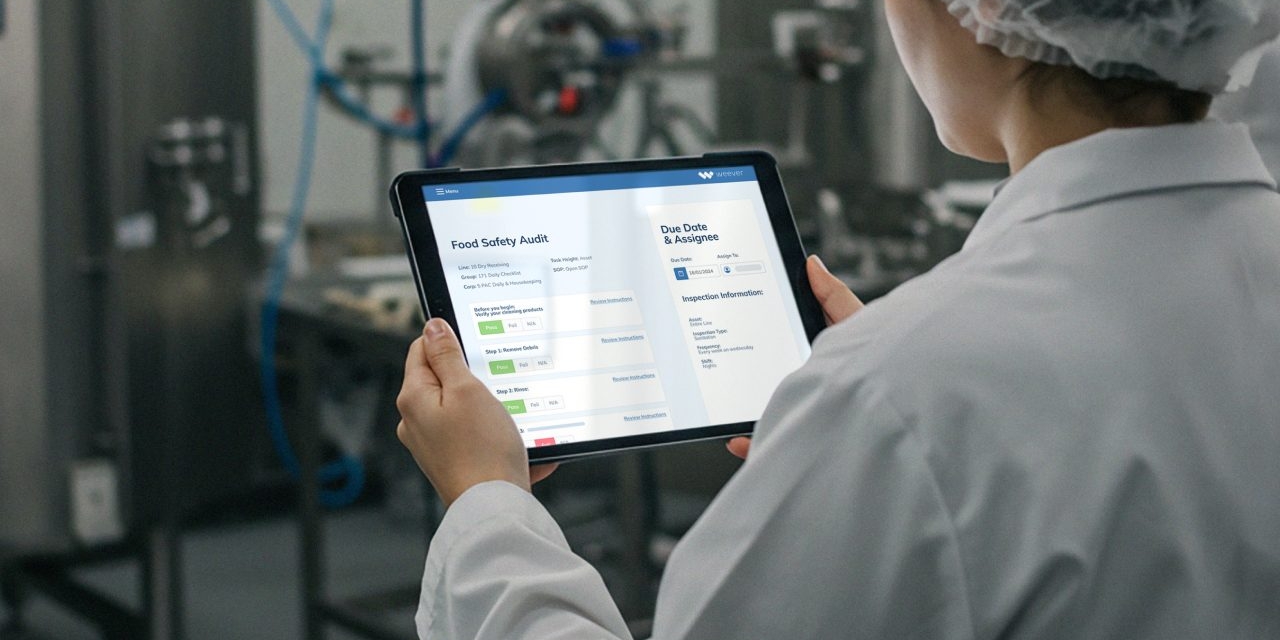

How can a food safety compliance management platform keep manufacturing operations risk-free?

How can a food safety compliance management platform keep manufacturing operations risk-free? Discover how Weever’s…

How Can Digital Transformation Solutions Revolutionize the Factory Floor for Frontline Workers?

How Can Digital Transformation Solutions Revolutionize the Factory Floor for Frontline Workers? Revolutionize your factory…

How Can Food and Beverage Manufacturers Scale Operations Without Compromising Sanitation Standards Using Weever Software?

How Can Food and Beverage Manufacturers Scale Operations Without Compromising Sanitation Standards Using Weever Software?…

How Can Leveraging Digital Transformation Enhance Autonomous Maintenance with Weever?

Leverage digital transformation with Weever to enhance Autonomous Maintenance. Simplify integration, automate workflows, gain insights, and improve efficiency.

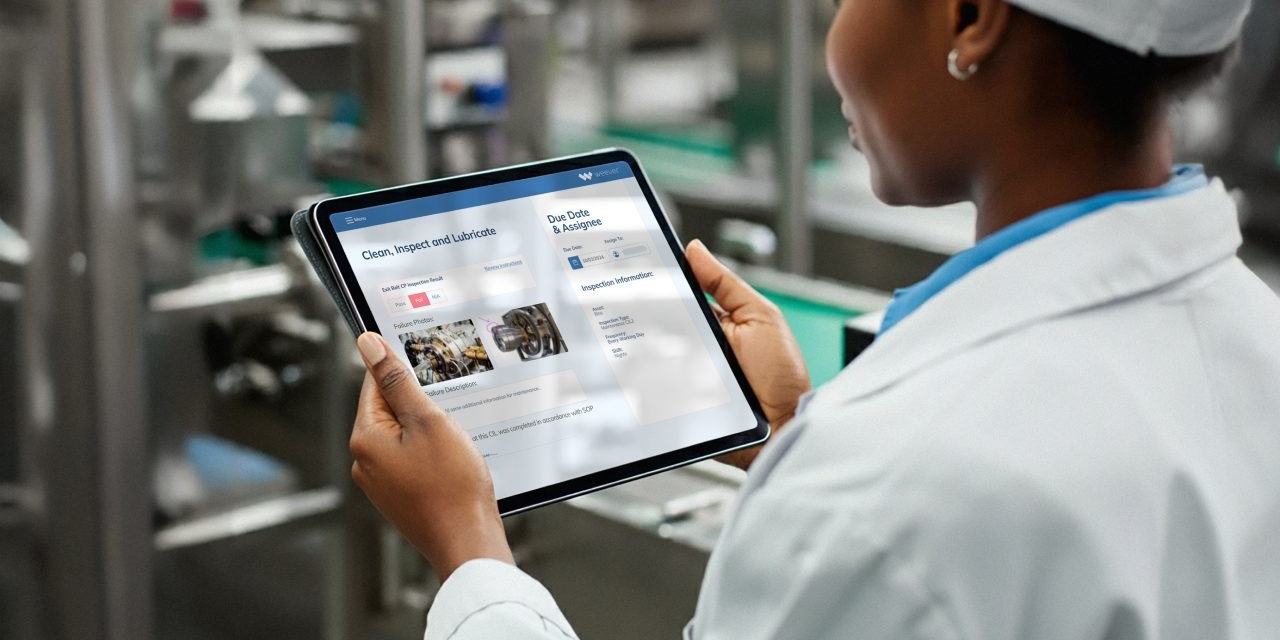

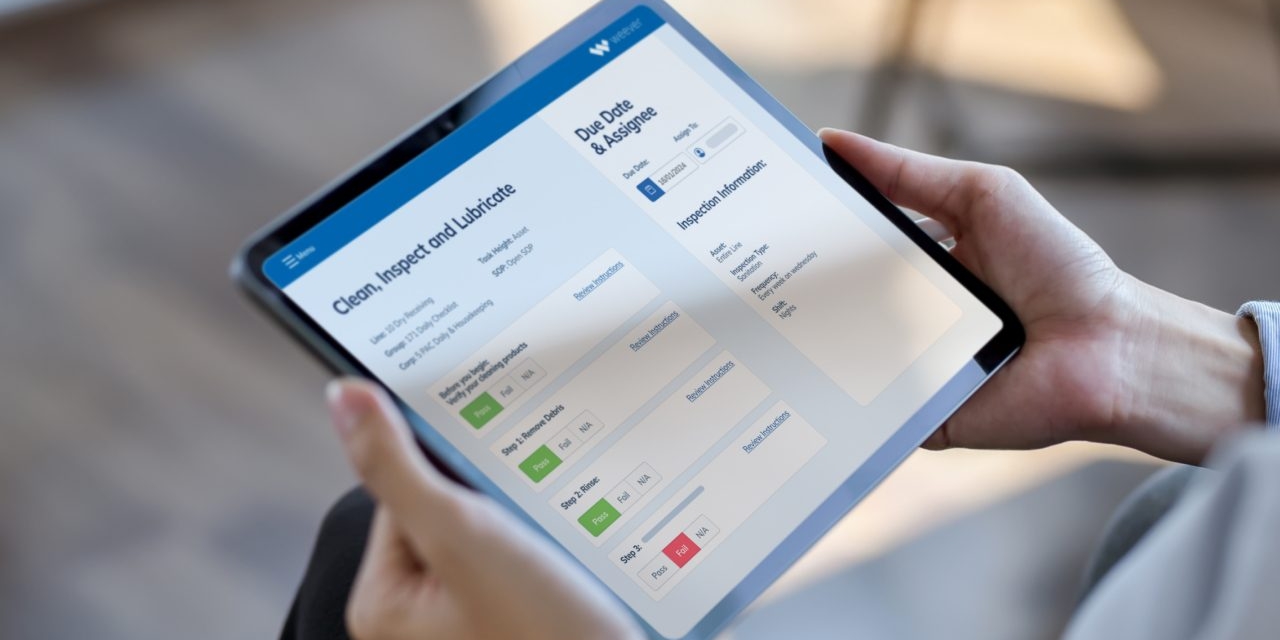

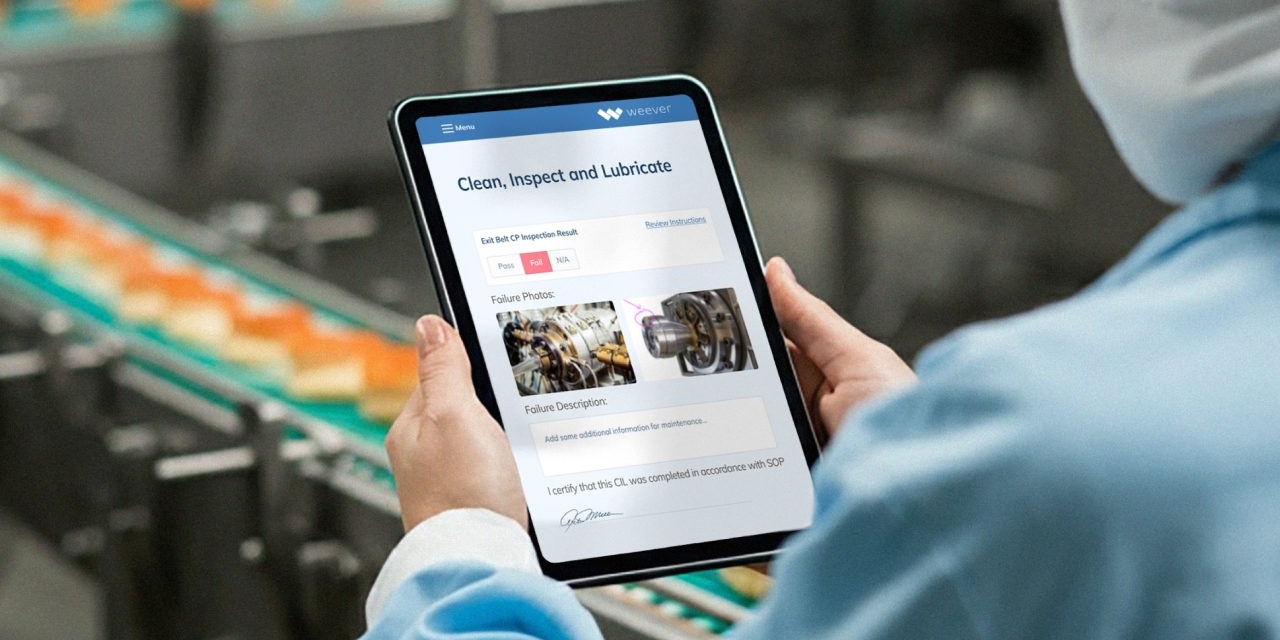

How Can Manufacturing Plants Create Efficient CIL Checklists Using Weever?

How Can Manufacturing Plants Create Efficient CIL Checklists Using Weever? Learn how Weever helps manufacturing…

How Can We Enhance Warehouse Productivity Through Autonomous Maintenance with Weever?

How Can We Enhance Warehouse Productivity Through Autonomous Maintenance with Weever? Boost warehouse productivity with…

How Can We Establish Effective Standards and Protocols for Lubrication and Inspection with Weever?

Boost efficiency and productivity in manufacturing operations with Weever Software’s configurable program templates. Learn how to streamline workflows and enhance performance.

How Can We Expand Autonomous Maintenance Practices Beyond Manufacturing, and How Does Weever Support Diverse Industries?

How Can We Expand Autonomous Maintenance Practices Beyond Manufacturing, and How Does Weever Support Diverse…

How Can We Maximize Efficiency in Food Industry Operations with Autonomous Maintenance, and How Can Weever’s Help?

Maximize efficiency in food industry operations with Weever’s Autonomous Maintenance solution. Learn how to optimize today.

How Do You Choose The Right Manufacturing Compliance Software For Your Business, And Why Does Weever Stand Out?

How Do You Choose The Right Manufacturing Compliance Software For Your Business, And Why Does…

How does automotive quality control tracking software drive efficiency in precision manufacturing?

How does automotive quality control tracking software drive efficiency in precision manufacturing? Discover how Weever’s…

How Does Autonomous Maintenance Serve as a Pillar for Continuous Improvement, and How Does Weever Strengthen This Foundation to Keep Businesses Ahead of Emerging Trends?

How Does Autonomous Maintenance Serve as a Pillar for Continuous Improvement, and How Does Weever…

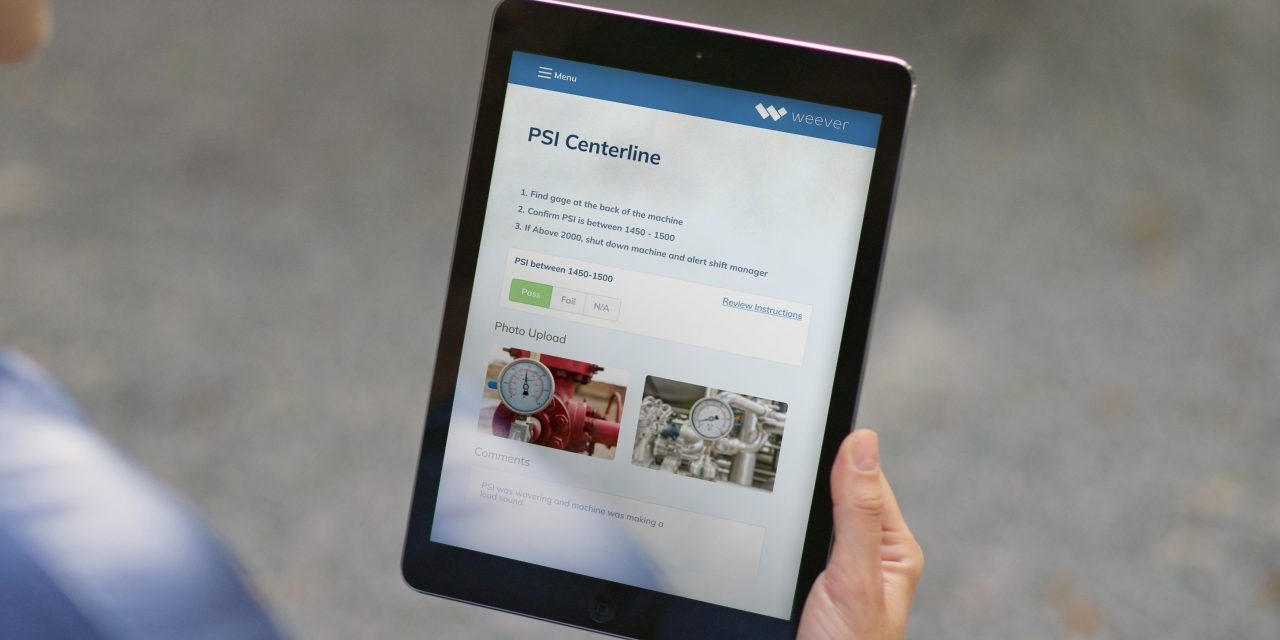

How Does Clean Inspect Lubricate (CIL) Work: A Step-by-Step Guide with Weever

How Does Clean Inspect Lubricate (CIL) Work: A Step-by-Step Guide with Weever Learn how Weever…

How Does Weever Software Drive Innovation and Compliance in Food and Beverage Manufacturing with Configurable Sanitation Programs?

How Does Weever Software Drive Innovation and Compliance in Food and Beverage Manufacturing with Configurable…

How Does Weever Software Enhance Food Safety and Support Autonomous Maintenance in Manufacturing?

How Does Weever Software Enhance Food Safety and Support Autonomous Maintenance in Manufacturing? Enhance food…

How Does Weever Software Help Manufacturers Overcome Common Challenges in Master Sanitation Schedules?

How Does Weever Software Help Manufacturers Overcome Common Challenges in Master Sanitation Schedules? Overcome MSS…

How Does Weever Software Help Manufacturing Plants Achieve Audit Readiness with Master Sanitation Schedules?

How Does Weever Software Help Manufacturing Plants Achieve Audit Readiness with Master Sanitation Schedules? Achieve…

How Does Weever Software Simplify Tracking the Frequency of Cleaning in Manufacturing Plants?

How Does Weever Software Simplify Tracking the Frequency of Cleaning in Manufacturing Plants? Streamline cleaning…

How Does Weever Software Streamline Planned Cleaning in Food Production?

In the food production and related industries, maintaining cleanliness is a non-negotiable priority. Effective sanitation ensures compliance with regulatory requirements, safeguards product quality, and upholds consumer trust. However, managing the planned cleaning of food manufacturing processes can be a complex challenge, involving multiple areas, equipment, and personnel.

How Does Weever Software Streamline Planned Cleaning in Food Production?

How Does Weever Software Streamline Planned Cleaning in Food Production? Streamline sanitation in food production…

How Does Weever Software Support Configurable Master Sanitation Schedules for Food Manufacturing Plants?

How Does Weever Software Support Configurable Master Sanitation Schedules for Food Manufacturing Plants? Streamline food…

How Does Weever Software Support Quality Assurance Through Planned Cleaning in Food Manufacturing?

How Does Weever Software Support Quality Assurance Through Planned Cleaning in Food Manufacturing? Streamline planned…

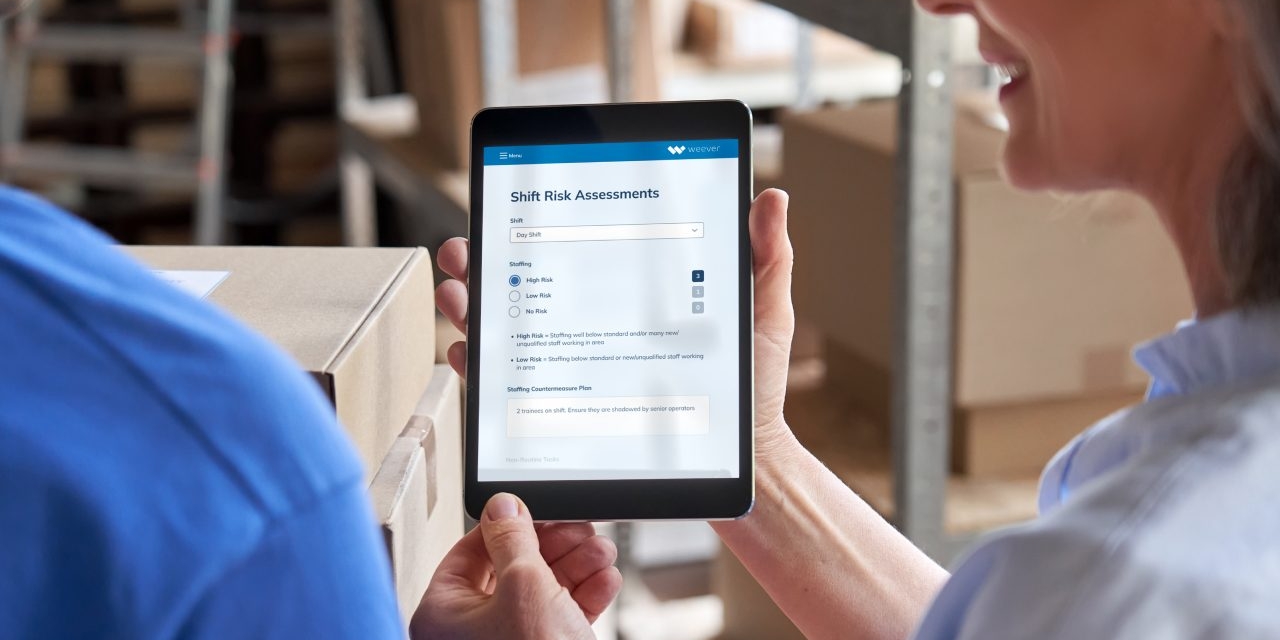

How does workflow automation help to reduce errors for operators at a manufacturing facility?

Workflow automation can help reduce errors for operators at a manufacturing facility in several ways. Automation ensures tasks are completed correctly every time, which reduces rework, defects and time-to-close maintenance tickets.

How does workflow automation increase collaboration in a manufacturing facility?

Workflow automation can increase collaboration in a manufacturing facility in several ways. By automating the flow of information between different systems and teams, manufacturers can improve communication and collaboration, leading to better decision-making and more efficient operations.

How does workflow automation reduce costs for manufacturing organizations?

Workflow automation can help manufacturing organizations reduce costs by eliminating waste, reducing errors, and improving efficiency. By automating routine tasks, manufacturers can save time and reduce the cost of labor-intensive manual processes.

How elevated safety increases employee engagement at manufacturing organizations

Elevated safety can have a positive impact on employee engagement at manufacturing organizations by building trust, boosting morale, reducing stress, increasing productivity, and improving retention.