Marks

Diageo

Niagara Bottling

Walmart

PepsiCo logo

McDonald's

Unilever

Monin

Hello Fresh

Rise Baking

Rockwool

Canadian Tire

SportChek

Greyston Bakery

Bell

Husqvarna

Home Hardware

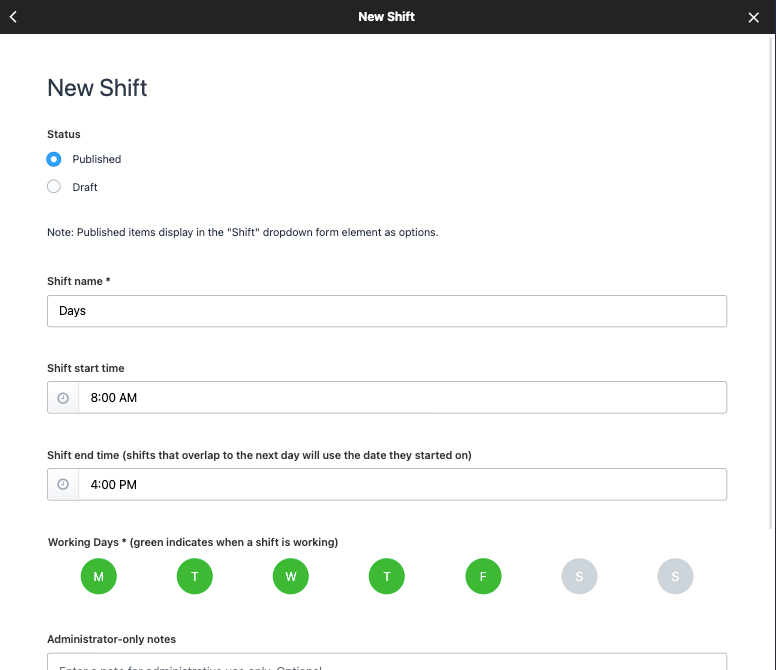

Build & Manage Schedules

Set it and forget it.

Add any audit and inspection form to your schedule. Set recurring and fixed schedules. Create blackout periods and bulk pause and resume as your operations require.

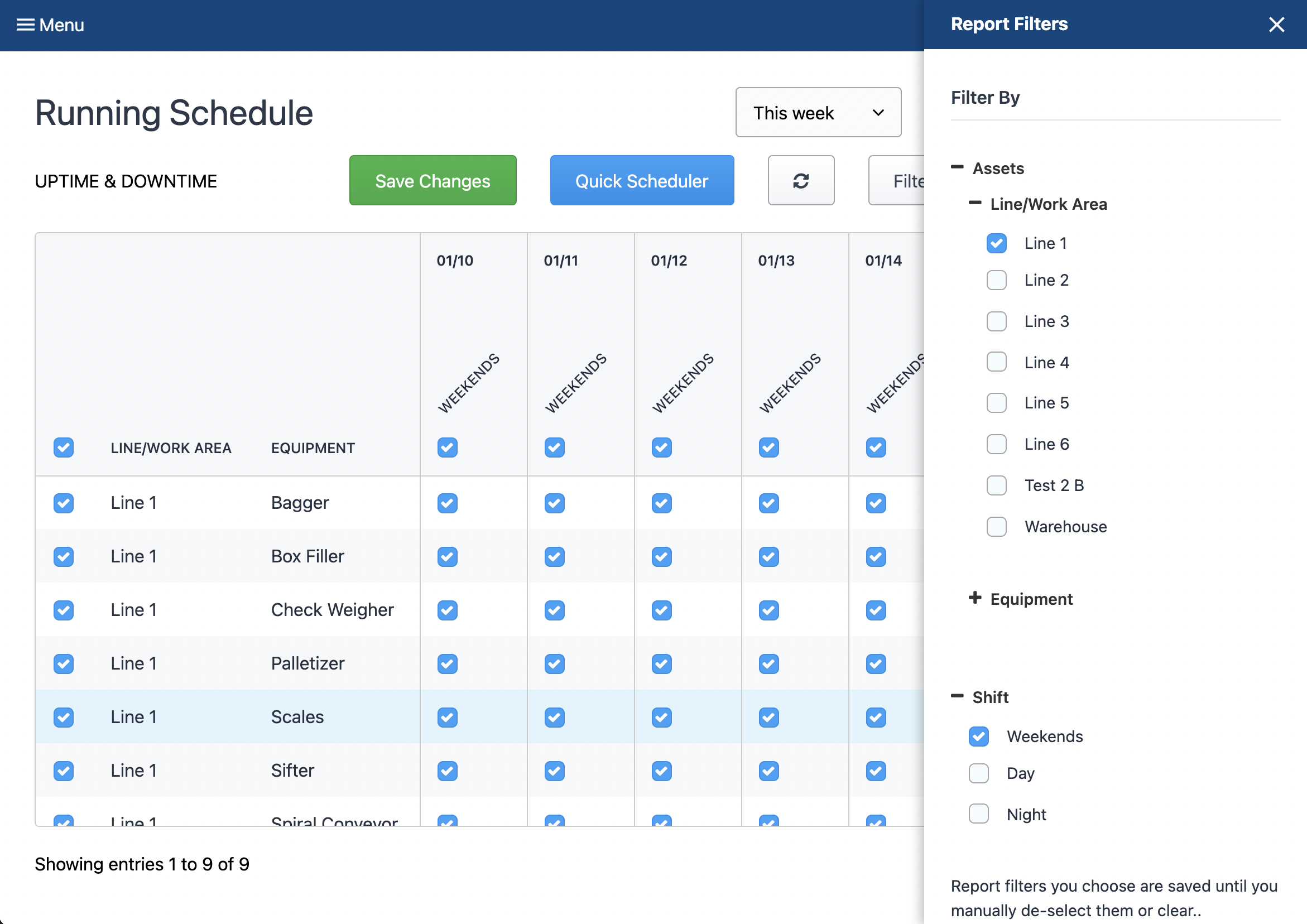

PAuse & REsume schedules

Add planned or unplanned downtime with a single click.

Downtime happens. That's why Weever added a number of tools to help our clients manage their inspection schedules to accommodate down time. Pause a single inspection, a machine or equipment, a line, a shift, or everything all at once.

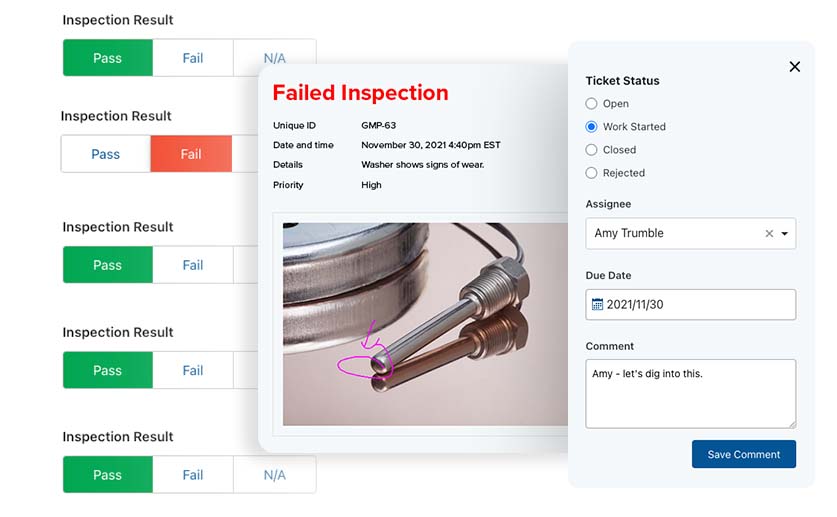

Receive alerts for failures.

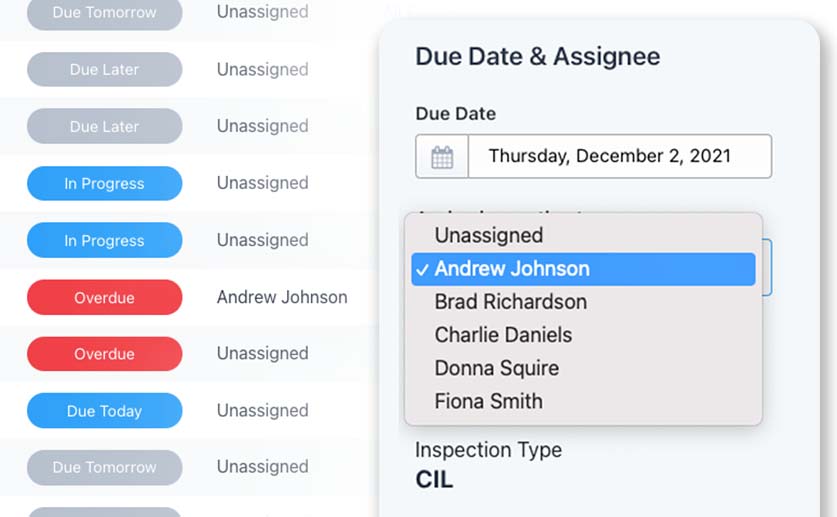

“Failed” inspections automatically create a ticket for supervisor evaluation. Assign action items. Add due date. Move work forward.

Ensure Accountability

Staff can be assigned inspections directly or they simply view what is due for the line they are working on.

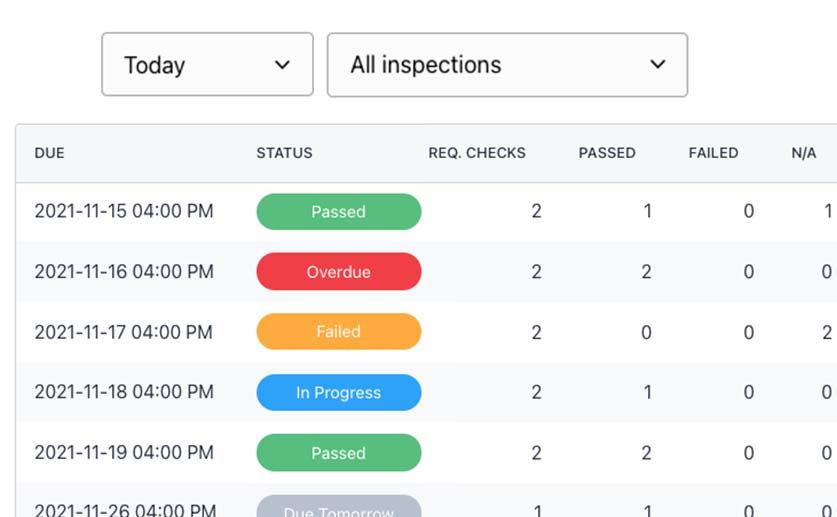

Understand everything at-a-glance.

Easily understand in real-time which inspections and audits have been completed, not started, overdue, passed, failed, etc.

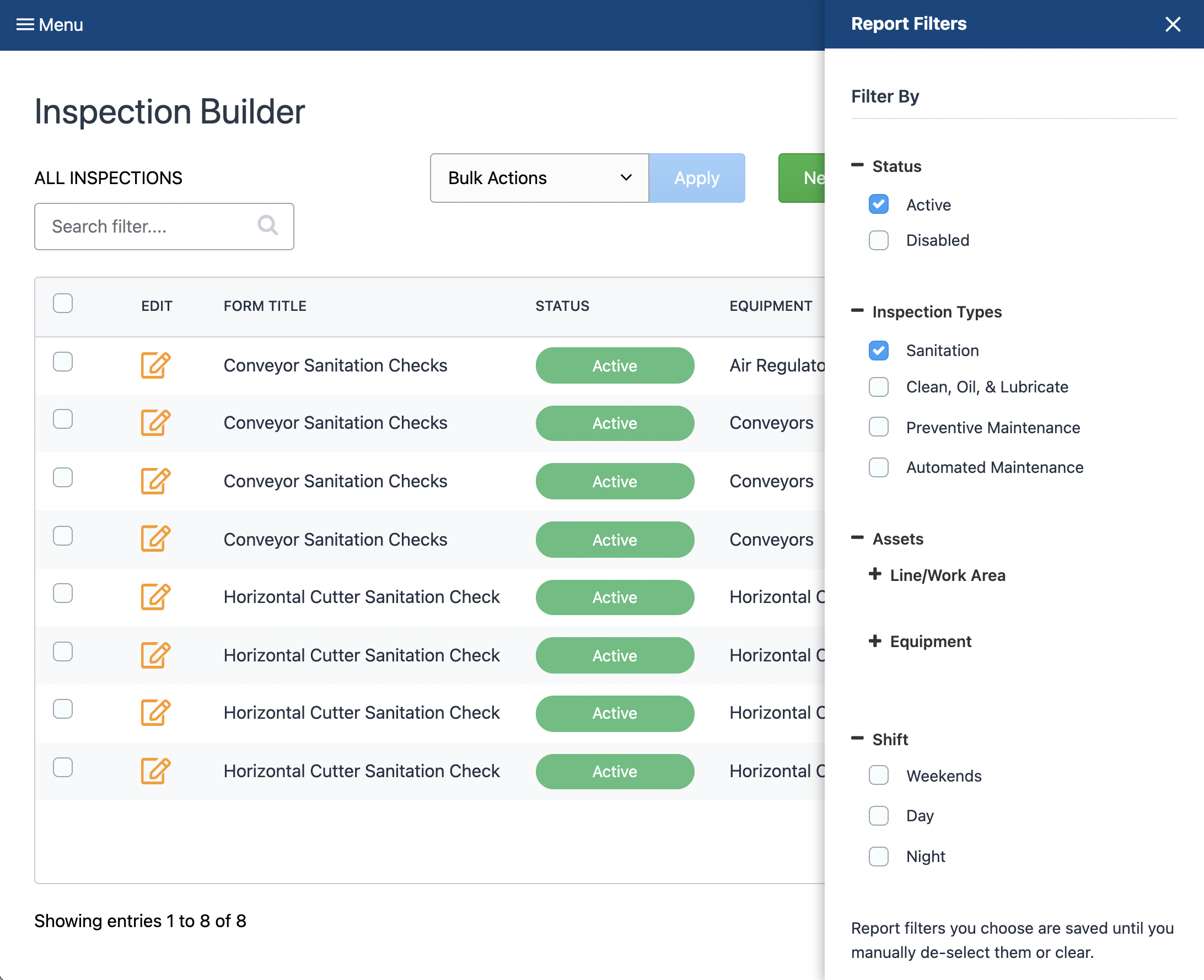

Scheduling Features

Flat list that shows every inspection in the entire system regardless of line or machine. Filter this view by line, machine, inspections type, shift, etc.

Download the Inspections Brochure

SCHEDULE A DEMO

Take a Guided Tour.

In just 30 minutes you will learn about customizing and using forms, workflow automation, reviewing reports, and sharing data with other business systems.

In just 30 minutes you will learn about customizing and using forms, workflow automation, reviewing reports, and sharing data with other business systems.