highlight

State of the Food Manufacturing Sanitation Industry Report 2023

Learn more about the food production line sanitation industry from the people who manage the work, including challenges and opportunities, training and retention, regulations, software and technology, and continuous improvement.

Read MoreMarks, Canadian Tire, Sportschek solves vendor non-compliance with Weever.

We needed a way to document non compliant shipments sent to us from our vendors in a way the clearly demonstrated the errors to the vendors. Additionally, we needed to capture this evidence from multiple locations with distribution to specific downstream teams (including the ability to have a file format that can be saved on an SFTP0 based on the location that identified the non compliance.

Read MoreTop 5 Benefits of Digitizing your Autonomous Maintenance Program

If you using paper forms, there are many benefits you can realize by switching to software, such as increased adoption, real-time escalation, on-demand instruction, rich data, and reducing the burden of administration.

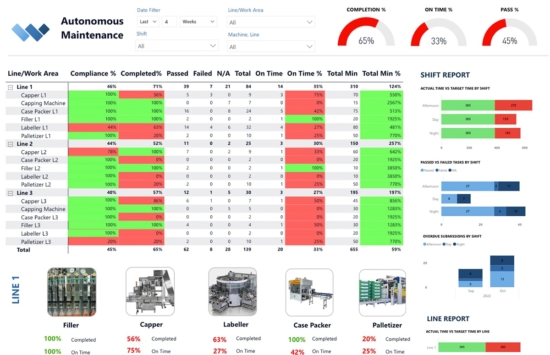

Read MoreAutonomous Maintenance Report

Is your Autonomous Maintenance scheduling being followed? What is compliance and failure rate by line, machine, shift, etc.?

Read MoreEpisode 3: Using Technology To Engage Employees in Manufacturing and Overcome Industry Staff Shortage with Jake Hall, The Manufacturing Millennial

In this episode, we are once again joined by Jake Hall for a second episode. We take a closer look at the industry labor force issue, why more automation is leading to the digitization of manual frontline SOPs, the growth of AI in manufacturing, how companies can attract and engage a tech-enabled workforce, and how technology can be used to get more from your existing resources.

Read MoreEpisode 2: Successful Digital Adoption Requires Patience and Purpose with Paul Nadolski, Continuous Improvement Manager at Kerry

In this episode, we are joined by Paul Nadolski, Continuous Improvement Manager at Kerry. Paul talks about why it’s important to build good habits before implementing technology, why defining the problem is the first piece to coming up with great solutions, and the importance of empathy and soft skills in manufacturing.

Read MoreEpisode 1: Industry 4.0: Going Paperless In Order To Increase Connectivity and Automation with Jake Hall, The Manufacturing Millennial

In this episode, we are joined by Jake Hall, an influencer who’s making waves about Industry 4.0 on social media as The Manufacturing Millenial. Jake explains how technology is the only way to solve a huge problem the industry is facing.

Read More5S Audit Report

Where, when and by whom are 5S audits occurring. What are the average scores by line, shift, etc. and what are the key outcomes?

Read MoreWhat are BBS Observations and how can software help?

Behavior-based Safety Observations are an integral part of modern safety programs. Let’s discuss how they work and how software can make them better.

Read More