How to Maximizing 5S Impact Through Action Items

Ensuring 5S Sustainability by correcting failures and continuously improving through action plans and follow-up audits.

5S Overview

5S Planning

5S Implementation

5S Auditing

5S Audit Digitization

FREE RESOURCEs

Central to the efficacy of 5S is the practice of auditing—a systematic evaluation ensuring adherence to 5S principles.

Implementing corrective actions and conducting follow-up audits are pivotal steps within the auditing process, playing a vital role in addressing deficiencies, driving improvement, and ensuring sustained progress.

Let's explore the essence of 5S auditing and unveil the significance of effective corrective actions and follow-up audits in 5S programs.

The Problem

5S Audit issues are not corrected

The 5S methodology, a fundamental part of lean manufacturing and continuous improvement, has the potential to revolutionize workplace organization, cleanliness, and efficiency. However, many 5S programs encounter a common pitfall - they are set up with great enthusiasm and effort but struggle to sustain their impact over time.

One of the primary reasons for this is the failure to address issues identified during the auditing process. When audits report failures, and these issues are not acted upon, it erodes the faith of auditors and frontline staff in the program's effectiveness.

The Solution

Effective Action Item Management

Action Items are specific tasks or actions assigned to correct the identified issues. When executed correctly, action items can breathe new life into a 5S program, ensuring that problems are not only identified but also resolved promptly. Let’s explore how to maximize the impact of your 5S program through action items, with a particular focus on leveraging digital platforms like Weever. We'll also delve into the concept of SMART action items and provide insights into creating efficient ones.

The Power of Action Items

Action items are specific, actionable tasks assigned to individuals or teams responsible for resolving identified issues. When executed effectively, action items can deliver the following benefits.

SMART Action Items: Making Them Efficient

To maximize the impact of action items, it's essential to make them SMART, which stands for Specific, Measurable, Achievable, Relevant, and Time-bound. Here's how to create SMART action items:

Steps-by-Step Guide to 5S Corrective Actions

Implementing effective corrective actions and conducting follow-up audits aren't merely tasks; they're integral components driving the success and sustained improvement of 5S programs. These steps enable organizations to address deficiencies, evolve processes, and cultivate a culture of continuous enhancement and excellence.

Before you can implement corrective action items, you will need to:

- Establish Audit Criteria and Checklists

- Train Auditors

- Schedule Audits

- Conduct Audits

- Generate & Review Reports

After implementing action items, you can move forward with:

- Celebrate Success and Recognition

1. Analyze Findings & Develop Action Plans

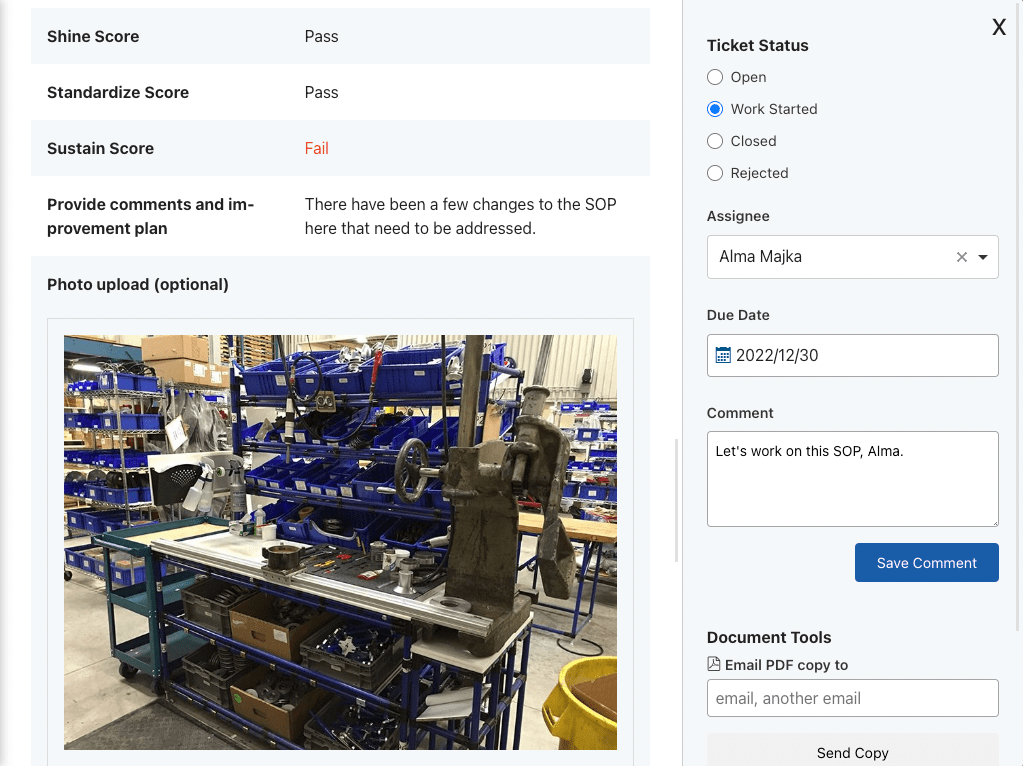

While you conduct your audits, the auditors should identify audit "failures" and outline corrective measures.

- Identify Non-Compliance Areas: Review audit reports to pinpoint specific deficiencies and areas needing improvement.

- Define Corrective Measures: Formulate clear and actionable plans to address identified deficiencies.

- Set Objectives: Establish specific goals and timelines for implementing corrective actions.

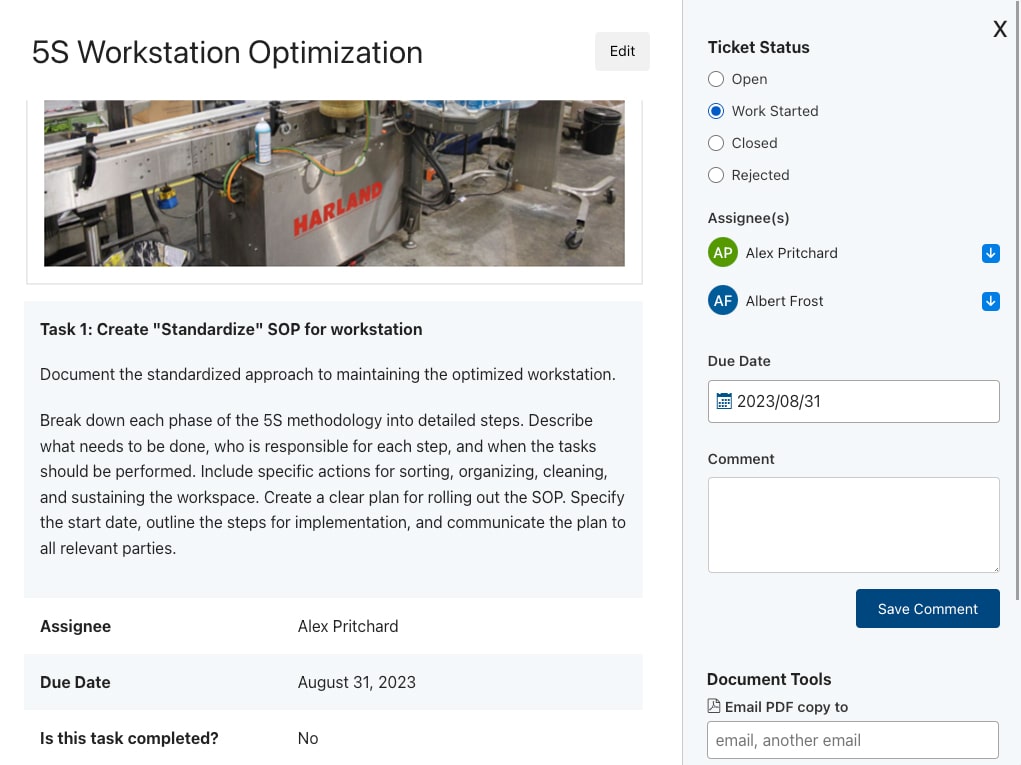

2. Assign & Prioritize

Ensure action plans are assigned with due dates to ensure accountability.

- Allocate Tasks: Assign responsibilities to individuals or teams for executing corrective measures.

- Ensure Accountability: Clarify roles and expectations to ensure accountability for implementation.

- Prioritize Issues: Determine which issues require immediate attention based on severity and impact

3. Implement Actions and Follow-Up Audits

Put strategies into action, addressing identified deficiencies systematically.

- Monitor Progress: Regularly track the implementation status to ensure timely execution.

- Schedule Re-assessments: Plan follow-up audits to evaluate the effectiveness of implemented corrective actions.

- Compare Against Previous Findings: Assess whether the corrective measures have resolved identified issues.

6. Analyze & Continuously Improve

Set benchmarks and measure results. Update processes, checklists and schedules to accommodate analysis findings.

- Evaluate Progress: Compare follow-up audit results with initial findings to gauge improvement.

- Adjust Strategies: Modify action plans as needed based on the effectiveness of implemented measures.

- Iterate and Refine: Use findings from follow-up audits to further refine processes and practices.

- Sustain Improvement: Integrate successful changes into standard practices to ensure sustained improvement.

bandjlogo

Bell-logo-New

Canadian-Tire-Logo

Diageo-customer-logo

greyston-bakery-logo

hello-fresh-customer

marks-customer-logo

CSL_Limited_logo

monin-logo

Winland Food

Mars-logo-main

rise-baking-customer-logo

Rockwool-Customer-Logo-min

Sportcheck-customer-logo

unilever-customer-logo

walmart-logo-small

husqvarna-customer-logo

Ajinomoto_logo

Peet's_Coffee_logo

Royal-Canin-Logo