Practical Guide to 5S Sorting

How to effectively identify and remove unnecessary items from workstations to radically enhance productivity.

5S Overview

5S Planning

5S Implementation

5S Auditing

5S Audit Digitization

FREE RESOURCEs

As your manufacturing facility gears up for a transformative "Optimization Blitz," the initial step of the 5S methodology, Sort, sets the stage for an efficient and organized workspace.

On the first day of the “blitz”, Frontline staff, working hand-in-hand with 5S leadership, will embark on the crucial task of sorting their workstations.

In this article we discuss an overview of the Sort step, the process involved, key considerations, and best practices to make this phase impactful.

But first, let’s review what 5S is and why it is important.

What is 5S?

The 5S methodology is a systematic approach aimed at organizing a workspace for efficiency and effectiveness. It consists of five steps, each starting with the letter "S":

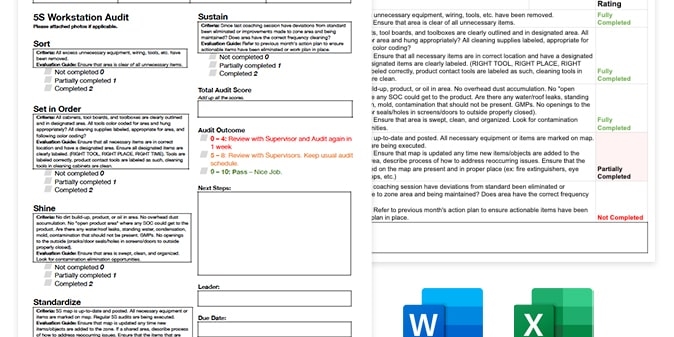

- Sort: Eliminate unnecessary items from the workspace, keeping only the essentials.

- Set in Order: Organize and arrange necessary items in a logical and accessible manner for easy retrieval and use.

- Shine: Clean the workspace regularly to maintain cleanliness and identify any issues or abnormalities.

- Standardize: Establish and maintain standardized work procedures to sustain the improvements made in the first three steps.

- Sustain: Develop a habit of maintaining the established standards and continuously improving the workspace.

This methodology is often applied in manufacturing, service industries, and various workplaces to streamline processes, reduce waste, and enhance productivity.

The Sort Step

Now that we understand the 5S methodology a bit better, let’s dig into understanding how to sort a workstation to maximize its productivity.

The Sort step aims to declutter workspaces by identifying and removing unnecessary items.

It's about distinguishing between what's needed (the essentials) and what's not (the clutter). By reducing unnecessary items, teams create streamlined, organized, and efficient work areas, laying the groundwork for improved productivity.

How to Sort a Workstation

The Sort step in the 5S methodology kickstarts the Optimization Blitz, fostering a workspace conducive to efficiency and productivity. Through collaborative efforts, clear guidelines, and a purposeful approach to sorting, frontline staff and 5S leaders can lay a strong foundation for subsequent steps, ensuring a streamlined and organized workspace for enhanced operations.

Here are the steps involved in completing an efficient sorting step.

Gather the Team

Assemble a team comprising frontline staff and 5S leaders to collaborate on the sorting process. Sorting is most effective when a team can work together to identify items, define criteria, separate and relocate.

Set Criteria

Define clear criteria for identifying non-essential items, considering factors like frequency of use, relevance to current processes, and condition. Some factors to consider include:

- Necessity: Determine what items are necessary for daily operations. Ask whether an item is essential for the work being done in that area. If not, consider removing it.

- Frequency of Use: Evaluate how often items are used. Items used regularly should be easily accessible, while those used infrequently can be stored in less accessible areas.

- Redundancy: Identify duplicate items and assess if they are all necessary. Redundant items can clutter the workspace and should be minimized.

- Purpose: Clarify the purpose of each item. If an item's purpose isn't evident or it serves no clear function, it might be a candidate for removal.

- Safety and Compliance: Ensure that items necessary for safety or regulatory compliance are readily available and properly stored. Anything related to safety or regulations should not be compromised.

- Future Needs: Consider potential future needs, but be cautious not to hoard items based solely on speculative future requirements. Balance current necessities with potential future use.

- Team Input: Involve the team working in the area during the sorting process. They likely have insights into what is necessary for their tasks and can contribute valuable perspectives.

Identify and Separate Items

Assess every item in the workspace, categorizing them into essential (needed for daily tasks) and non-essential (obsolete, rarely used).

Segregate items into "Keep," "Discard," or "Reallocate" categories based on the established criteria.

Dispose or Relocate

Discard obsolete items responsibly or relocate them to designated storage areas outside the immediate workspace.

Items categorized for relocation should be transferred to designated storage areas, keeping them away from the immediate workspace but still easily accessible if needed. Ensure these storage areas are organized, labeled, and easily navigable. This prevents clutter and supports efficient retrieval when required.

Ensure responsible disposal methods, which might include recycling, donation, or proper waste disposal as per company policies and environmental regulations. Maintain records of items being discarded, noting reasons for disposal. This documentation aids in tracking progress and making informed decisions in the future.

Interested in learning more about Weever?

Best Practices for an Effective Sort

For best results during the sorting process ensure you encourage and open dialogue, set clear criteria and document what was removed and why. Here are some additional best practices that you might consider:

Collaborative Approach

Encourage open communication and collaboration among team members during sorting.

Clear Guidelines

Provide clear criteria and guidelines to facilitate decision-making during item sorting.

Continuous Improvement Mindset

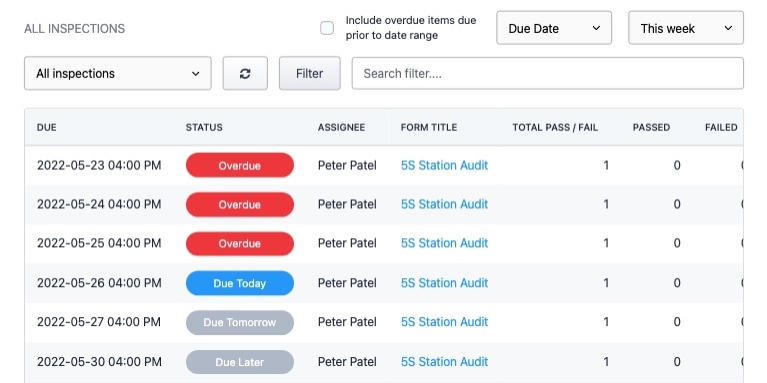

Instill a culture of ongoing sorting to prevent re-accumulation of unnecessary items. Use 5S audits to capture improvement insights.

Documentation

Keep records of discarded items and reasons for removal to track progress and inform future decisions. It is helpful to include before and after photos for each section in the workstation. These can be used to build Standardization SOPs and Audit checklists later in the 5S process.

Read our Ultimate Guide for 5S Auditing

Continue Learning about 5S

bandjlogo

Bell-logo-New

Canadian-Tire-Logo

Diageo-customer-logo

greyston-bakery-logo

hello-fresh-customer

marks-customer-logo

CSL_Limited_logo

monin-logo

Winland Food

Mars-logo-main

rise-baking-customer-logo

Rockwool-Customer-Logo-min

Sportcheck-customer-logo

unilever-customer-logo

walmart-logo-small

husqvarna-customer-logo

Ajinomoto_logo

Peet's_Coffee_logo

Royal-Canin-Logo