How to Standarize in 5S

Ensure processes, procedures, and practices adhere to a defined standard, facilitating consistency and predictability in manufacturing.

5S Overview

5S Planning

5S Implementation

5S Auditing

5S Audit Digitization

FREE RESOURCEs

For manufacturing facilities, precision, consistency, and efficiency reign supreme. The 5S methodology stands as a beacon, guiding industries toward optimized operations. Among its fundamental steps, standardization holds a pivotal role in ensuring uniformity, reliability, and continuous improvement. Let's explore how standardization fuels the essence of 5S within manufacturing environments.

What role does Standardize play in 5S?

5S is a methodology deeply rooted in Japanese practices, emphasizing the principles of workplace organization and visual management. The five steps—Sort, Set in Order, Shine, Standardize, and Sustain—form a comprehensive system to enhance productivity, safety, and quality.

Standardization, the fourth step, plays a crucial role by establishing and maintaining uniformity in the application of the 5S methodology across workstations. It ensures that processes, procedures, and practices adhere to a defined standard, facilitating consistency and predictability.

How to Standardize Workstations in Manufacturing

Follow these steps to standardize the implementation of 5S within a workstation:

Standardization Step-by-Step Guide

The success of standardization lies in its integration into the organizational DNA, where it becomes second nature to all involved—a true testament to the power of the 5S methodology in manufacturing. Follow these steps to standardize the 5S methodology:

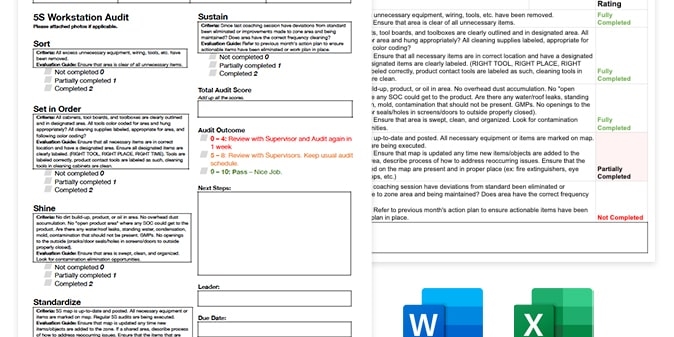

1. Define Clear Standards

- Establish comprehensive guidelines detailing how each 5S step should be executed.

- Specify expectations for organization, cleanliness, safety protocols, and visual cues.

2. Develop Standardization Procedures

- Create step-by-step procedures for implementing each 5S step.

- Provide training and resources to ensure everyone understands and follows these procedures.

3. Implement Visual Management

- Use visual cues such as color coding, labels, and signage for clear identification of tools, materials, and designated areas.

- Visual aids should convey standardized processes and expectations.

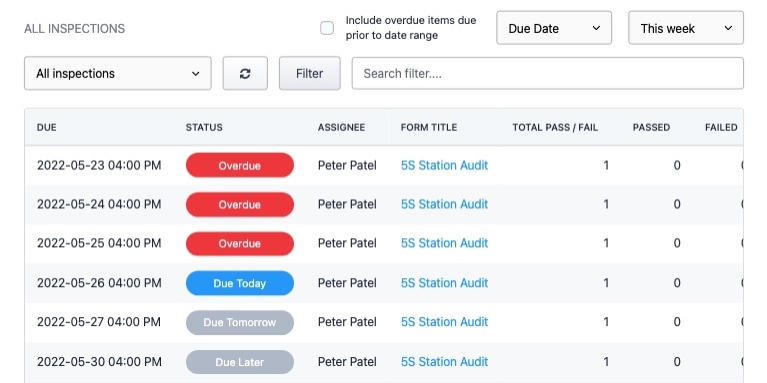

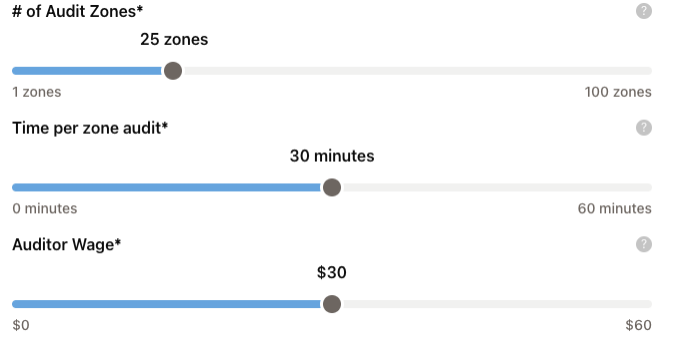

4. Regular Audits and Assessments

- Conduct frequent audits to assess adherence to standardized practices.

- Gather feedback and data to identify areas for improvement and adjust standards as necessary.

5. Documentation and Communication

- Document standardized procedures and guidelines for easy reference.

- Communicate changes or updates in standards promptly and effectively to all stakeholders.

Interested in learning more about Weever?

Standardization Best Practices

Standardization within the 5S methodology is more than just enforcing rules; it’s about creating an environment that thrives on consistency, efficiency, and continual enhancement. By standardizing practices, organizations pave the way for sustained improvement and operational excellence.

Standardization best practices encompass engaging stakeholders at all levels, fostering a culture of continuous improvement, prioritizing comprehensive training, securing support from leadership, and celebrating achievements.

Engage Stakeholders

Involve employees in the standardization process to gather insights and increase buy-in.

Continuous Improvement

Regularly review and refine standards based on feedback, performance data, and changing needs.

Training and Education

Ensure all team members are adequately trained and informed about standardized practices.

Leadership Support

Gain support from management to prioritize and maintain standards across the organization.

Celebrate Success

Acknowledge and celebrate achievements in adherence to standards to foster a culture of excellence.

Read our Ultimate Guide for 5S Auditing

Continue Learning about 5S

bandjlogo

Bell-logo-New

Canadian-Tire-Logo

Diageo-customer-logo

greyston-bakery-logo

hello-fresh-customer

marks-customer-logo

CSL_Limited_logo

monin-logo

Winland Food

Mars-logo-main

rise-baking-customer-logo

Rockwool-Customer-Logo-min

Sportcheck-customer-logo

unilever-customer-logo

walmart-logo-small

husqvarna-customer-logo

Ajinomoto_logo

Peet's_Coffee_logo

Royal-Canin-Logo