The Benefits of Automated Audit Checklists in Manufacturing

Discover how Weever's automated audit checklists can streamline your manufacturing operations, enhancing efficiency, accuracy, and compliance.

5S Overview

5S Planning

5S Implementation

5S Auditing

5S Audit Digitization

FREE RESOURCEs

In the realm of manufacturing, efficiency and organization are paramount. One methodology that stands out for its effectiveness is 5S, a systematic approach to workplace organization derived from five Japanese words: Seiri (Sort), Seiton (Set in order), Seiso (Shine), Seiketsu (Standardize), and Shitsuke (Sustain). 5S enhances productivity and creates a safer, cleaner work environment by eliminating waste, improving process flow, and reducing operational costs.

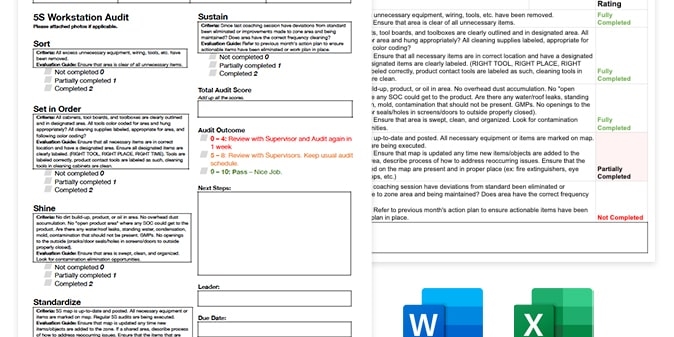

Traditional 5S audits, often managed through paper-based systems, present several challenges in manufacturing. Primarily, they are time-consuming, diverting valuable resources from production to paperwork. Such manual entries are prone to inaccuracies due to human error, compromising the reliability of audit results. Moreover, paper-based audits cannot provide data collected in real-time, delaying critical insights needed for immediate decision-making and improvement. This lag can hinder the dynamic response required to maintain high operational efficiency and compliance standards in fast-paced manufacturing environments.

Weever's Automated Audit Checklists Elevate 5S Implementation in Manufacturing

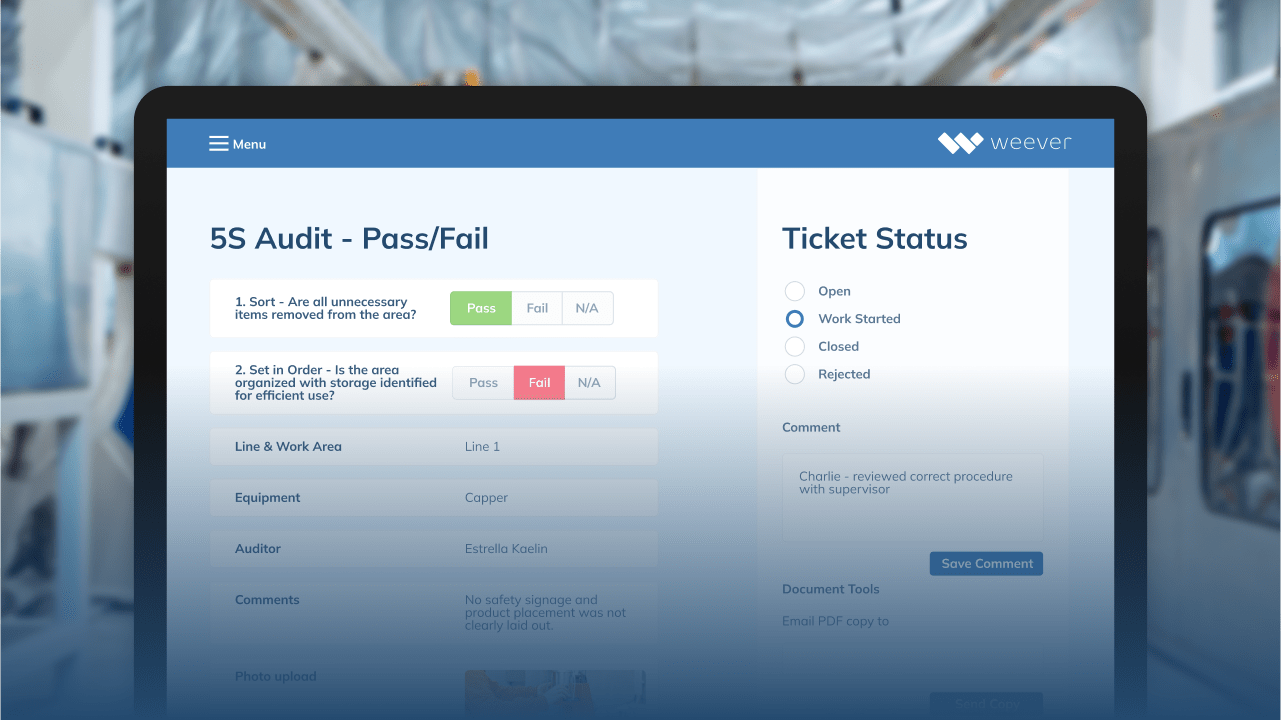

Transitioning from traditional manual processes, Weever’s automated audit checklists transform how manufacturers uphold 5S principles. Weever’s platform offers significant advantages:

- Consistency and Accuracy: Automation ensures that each step of your audit process is performed consistently and correctly, reducing human error and increasing reliability.

- Efficiency: Weever’s configurable audit templates streamline the setup process, making it easier and quicker to conduct regular audits.

By integrating Weever’s automated solutions, manufacturers can effectively apply 5S principles, enhancing both productivity and compliance, leading to a more organized and efficient workplace.

Weever’s Digital Solutions for 5S Audits in Manufacturing

Configurable Audit Checklists for Manufacturing Operations

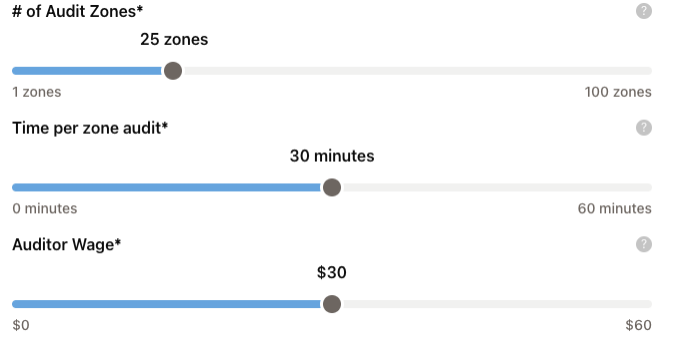

Weever transforms 5S audits with its digital solutions, offering configurable audit checklists tailored to the unique needs of each manufacturing environment. Unlike rigid paper-based systems, Weever’s audit checklists can be easily adjusted to address specific operational requirements, regulatory standards, and industry practices. This adaptability ensures that manufacturers can maintain a consistent audit process that truly reflects their operational landscape.

The benefits of using Weever’s configurable checklists are manifold. They enhance consistency across audits, ensuring all areas of the manufacturing process are regularly reviewed against uniform standards. This not only supports compliance with industry regulations but also bolsters overall operational efficiency. With Weever, manufacturers gain the flexibility to adapt their audit protocols as their business evolves, maintaining high standards of quality and compliance.

Optimize Manufacturing with Improved Error Reduction and Process Standardization

Automated audit checklists are a game-changer in the manufacturing sector, significantly enhancing the standardization and reliability of the 5S audit process. Companies can ensure that 5S or other methodologies are uniformly applied across different teams and shifts, eliminating variations that arise from manual handling and individual discrepancies.

Standardization is key to reducing errors in the audit process; with Weever’s automated checklists, every team member follows the same precise protocol, leading to consistent data collection and analysis. Consistency in standardization of processes minimizes the likelihood of errors, but also bolsters the overall reliability of manufacturing processes. As a result, companies experience fewer operational disruptions and can maintain a high level of quality control, enhancing both productivity and compliance in their manufacturing operations.

Access to Manufacturing Operations Data

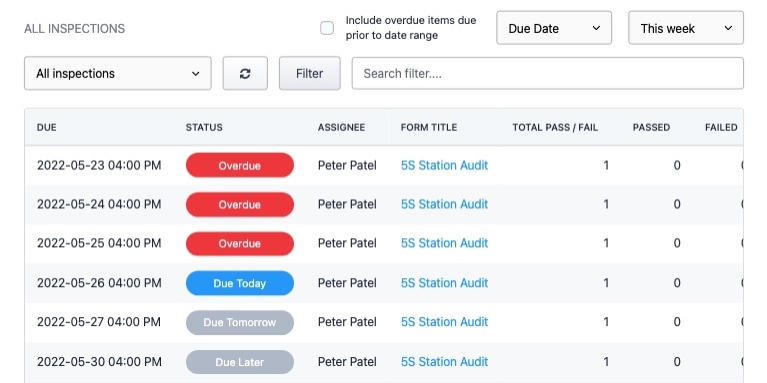

The ability to respond quickly to operational inefficiencies is crucial. Data collected in real-time is essential for identifying issues as they occur and implementing immediate corrective actions. Weever’s digital audit tools are designed to facilitate this need by providing instant data capture and access during 5S audits.

With Weever, data from audits is collected and made available, allowing for prompt analysis and action. This capability enables manufacturing supervisors and managers to quickly address any deviations from standards, update procedures, and communicate changes across teams without delay. The result is a more agile manufacturing process where continuous improvement is driven by immediate insights and operational transparency. Weever’s solutions ensure that manufacturers can maintain high standards of quality and efficiency, adapting swiftly to new challenges as they arise.

Manufacturing Insights on the Go

In the fast-paced world of manufacturing, mobile accessibility is crucial. Weever leverages mobile technology to enable staff to perform and log audits directly from their handheld devices, anywhere on the factory floor. This streamlined capability ensures audits are conducted efficiently and with minimal disruption to daily operations. Weever's automated audit checklists not only revolutionize data collection, but also transform this data into actionable insights that drive continuous improvement. Advanced analytics capabilities allow manufacturers to integrate audit data into reporting dashboards, quickly identifying trends, pinpointing inefficiencies, and suggesting actionable enhancements.

Moreover, the platform’s dashboards track the effectiveness of these improvements over time, providing evidence-based feedback on their impact. This continuous feedback loop fosters a culture of relentless refinement and optimization, ensuring manufacturing processes remain competitive and compliant with industry standards. By integrating seamlessly with key business systems like Microsoft Power BI or Tableau, Weever eliminates data silos, promotes interdepartmental communication, and ensures a cohesive flow of information across systems.

Weever's commitment to mobile accessibility and robust integration capabilities make it an essential tool for modern manufacturing environments, empowering efficiency, fostering continuous improvement, and turning routine data into a strategic blueprint for operational excellence.

Future-Proofed Manufacturing with Weever Automation

Weever’s automated audit checklists offer a powerful solution to enhance operational efficiency, standardize processes across teams and shifts, and significantly reduce errors. By transforming data into actionable insights, Weever helps drive continuous improvement, ensuring your operations are efficient and compliant.

Explore how Weever can transform your audit strategies and operational efficiencies by visiting our website. Schedule a demo today to see our tools in action and discover firsthand the difference Weever can make in your manufacturing environment.

Read our Ultimate Guide for 5S Auditing

Continue Learning about 5S

bandjlogo

Bell-logo-New

Canadian-Tire-Logo

Diageo-customer-logo

greyston-bakery-logo

hello-fresh-customer

marks-customer-logo

CSL_Limited_logo

monin-logo

Winland Food

Mars-logo-main

rise-baking-customer-logo

Rockwool-Customer-Logo-min

Sportcheck-customer-logo

unilever-customer-logo

walmart-logo-small

husqvarna-customer-logo

Ajinomoto_logo

Peet's_Coffee_logo

Royal-Canin-Logo