Optimizing Your Manufacturing 5S Audit Process with Weever's Digital Tools

Optimize your manufacturing 5S audit process with Weever's digital tools. Enhance productivity, ensure safety, and foster continuous improvement in your operations.

5S Overview

5S Planning

5S Implementation

5S Auditing

5S Audit Digitization

FREE RESOURCEs

The 5S methodology is a cornerstone of manufacturing efficiency, designed to optimize the physical workspace for enhanced productivity and safety. Originating from five Japanese terms translated into English — Sort, Set in Order, Shine, Standardize, and Sustain — 5S helps manufacturers reduce waste, streamline operations, and create a disciplined work environment. Each step is crucial, from eliminating unnecessary items (Sort) to maintaining discipline through regular audits (Sustain).

Weever's digital tools bring these traditional practices into the modern age. With configurable digital solutions, Weever transforms the 5S audit process, making it more adaptable to the specific needs of manufacturing environments. Our software replaces cumbersome paperwork with intuitive, easy-to-navigate digital interfaces, allowing for real-time data capture and immediate feedback. This seamless integration ensures that all levels of the manufacturing process are aligned, significantly reducing errors and enhancing compliance. By adopting Weever’s digital tools, manufacturers can expect a streamlined audit process that not only supports sustained operational excellence but also fosters a culture of continuous improvement.

You may think traditional paper-based 5S audit processes work great. After all, they have helped grow and sustain manufacturing operations for decades. Let’s consider some of the challenges these older methods confront in modern manufacturing.

Challenges in Traditional 5S Audit Processes in Manufacturing

Traditional 5S audits in manufacturing often rely on paper-based systems that are prone to significant challenges. These manual processes consume excessive time, as data must be collected, recorded, and analyzed by hand, diverting valuable resources away from core manufacturing activities. Paper records are not only cumbersome to manage but also susceptible to human errors, leading to inaccuracies that can compromise the integrity of your 5S audits. Moreover, the lack of real-time data means that issues can go unnoticed until they escalate, preventing timely corrective action. Paper records can also be lost, damaged, or destroyed, and redundancy processes to safeguard them can become costly and complicated.

Weever's digital tools address these pain points by automating and streamlining the 5S audit process. Your manufacturing operation can eliminate paper, reduce errors, and access crucial data instantly on the Cloud—enhancing the efficiency, accuracy, and integrity of your audits.

Weever’s Digital Solutions for 5S Audits in Manufacturing

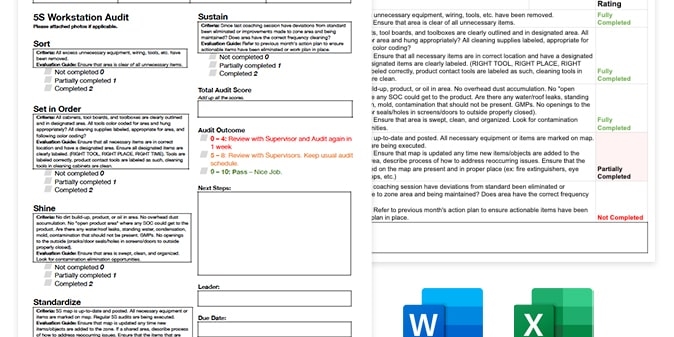

1. Configurable Digital Checklists

Weever's configurable digital checklists can be tailored to your specific needs as a manufacturer, empowering your 5S audits. These configurable checklists ensure that every audit is relevant and effective, addressing the precise criteria essential for your environment. The adaptability of Weever's software guarantees consistency across all audits, establishing a standard benchmark for order and efficiency that is vital for maintaining compliance with both industry regulations and internal standards. Weever’s user-friendly platform allows for quick updates, keeping your processes agile and responsive.

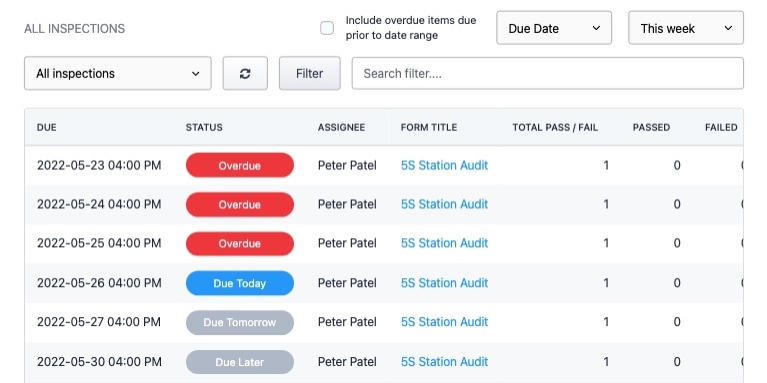

2. Real-Time Data Collection and Access

In the fast-paced world of manufacturing, real-time data is a game-changer. Weever’s digital tools empower you with instant data capture and access directly on the factory floor, enabling immediate corrective actions and timely updates. This immediacy ensures that any deviations from 5S standards are addressed swiftly, preventing small issues from becoming costly problems. With Weever's intuitive interface, team members can easily record and retrieve data without disrupting their workflow, enhancing overall efficiency. By incorporating Weever's solutions into your 5S audits, you can maintain a consistently high standard of operational excellence, ensuring that your manufacturing processes run smoothly and efficiently at all times.

3. Error Reduction and Process Standardization

Weever's digital solutions are key to standardizing the 5S audit process across various teams and shifts in your manufacturing settings. Our tools ensure that every participant, regardless of their role or time of work, follows the same procedures and criteria, fostering a unified approach to operational excellence. This standardization significantly reduces errors by eliminating the inconsistencies that often arise from manual processes. Moreover, it enhances process reliability as all team members have clear, consistent guidelines and expectations. With Weever, you can maintain a high level of precision and efficiency in your 5S audits, boosting overall productivity and quality.

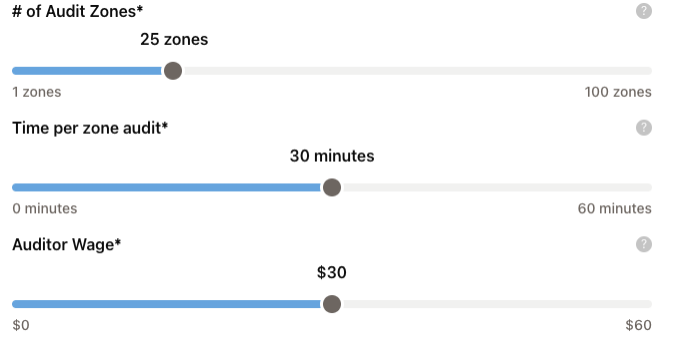

4. Analytics and Insights for Continuous Improvement

Weever’s software does more than streamline your 5S audits; it transforms audit data into actionable insights that drive best practice sharing in manufacturing operations. Supervisors can deep dive into 5S audit results, highlighting trends, pinpointing inefficiencies, and suggesting areas for enhancement. Managers and business analysts can use this robust data to make informed decisions, continuously refining processes and increasing productivity from a strategic level. For example, insights from Weever can reveal recurring bottlenecks at a particular workstation, allowing you to implement targeted improvements in that specific area.

5. Mobile Accessibility and Integration

In today’s dynamic manufacturing environments, mobile accessibility is crucial. Weever’s digital solutions are designed for on-the-go access, enabling teams to conduct 5S audits directly from mobile devices. This flexibility allows for immediate data entry and retrieval anywhere on the factory floor, streamlining communication and ensuring timely updates.

Moreover, Weever’s digital tools seamlessly integrate with other business software, such as Microsoft Power BI, Tableau, Looker, and much more, enhancing data consistency and workflow efficiency. This integration capability means information flows smoothly between systems, reducing manual data entry errors and providing a comprehensive overview of operations. Adopting Weever’s mobile and integrated solutions not only boosts operational agility but also strengthens decision-making, ultimately leading to a more responsive and productive manufacturing process.

Transformation Towards Manufacturing Excellence with Weever

Embracing Weever’s digital tools for your 5S audits is more than an upgrade—it's a transformative step towards manufacturing excellence. By replacing outdated, paper-based systems with our sophisticated, user-friendly digital solutions, you empower your team to perform more effectively and efficiently. Weever not only simplifies the audit process but elevates it, enabling you to harness the full potential of real-time data and analytics for continuous improvement.

With features like configurable digital checklists, instant data access, and seamless system integration, Weever ensures that your manufacturing operations can meet the demands of modern challenges and future opportunities. By standardizing processes, reducing errors, and providing actionable insights, our software helps secure a competitive edge in a rapidly evolving industry.

Join the multitude of successful manufacturers who have enhanced their operational efficiency with Weever. Invest in your future today and build a foundation for sustained success. Let Weever take your 5S audits to the next level and watch as your manufacturing processes thrive.

Read our Ultimate Guide for 5S Auditing

Continue Learning about 5S

Marks

Diageo

Niagara Bottling

Walmart

PepsiCo logo

McDonald's

Unilever

Monin

Hello Fresh

Rise Baking

Rockwool

Canadian Tire

SportChek

Greyston Bakery

Bell

Husqvarna

Home Hardware