The Role of Audit Checklists in Enhancing Quality Control

Discover how audit checklists enhance quality control in manufacturing by identifying issues early and ensuring compliance. Explore Weever’s solutions today.

5S Overview

5S Planning

5S Implementation

5S Auditing

5S Audit Digitization

FREE RESOURCEs

Maintaining high-quality standards in manufacturing is essential for success. Every product leaving the factory must meet strict quality benchmarks to satisfy customers and stay competitive. Audit checklists play a crucial role in ensuring these high standards. They help manufacturers keep track of every step in the production process, making sure each one meets the required quality criteria. This blog will focus on how audit checklists enhance quality control by identifying areas for improvement. By using these checklists, manufacturers can catch potential issues early, streamline processes, and continuously improve product quality. We'll explore the key features of effective audit checklists and how they contribute to maintaining excellence in manufacturing.

Audit Checklists Ensure Higher Quality Standards

Audit checklists ensure every step of the production process meets strict quality standards. Regular audits help identify defects early, preventing small issues from becoming major problems. Near miss reporting software is a valuable tool in this process, as it helps catch potential quality issues before they occur, promoting proactive measures. Additionally, using observation forms to document quality checks provides a clear record of compliance and helps track improvements. By integrating these tools, manufacturers can maintain high standards, reduce defects, and continuously improve product quality.

Enable Proactive Measures with Audit Checklists

Audit checklists support proactive measures in quality control by identifying potential issues before they become major problems. Near miss reporting software plays a crucial role in this process, allowing manufacturers to detect and address minor issues early, preventing them from escalating into serious quality concerns. Predictive maintenance also helps avoid equipment-related problems by monitoring machinery and scheduling maintenance before failures occur. This proactive approach ensures smoother operations, reduces downtime, and maintains high product quality. By using audit checklists, near miss reporting software, and predictive maintenance, manufacturers can stay ahead of potential issues and continuously improve their processes.

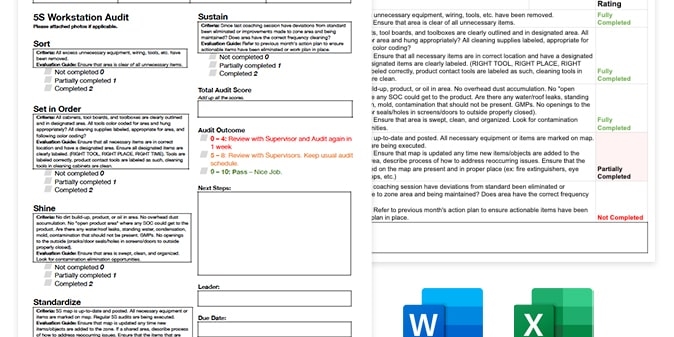

Utilizing 5S Audit Scorecards as an Audit Checklist

The 5S principles—Sort, Set in Order, Shine, Standardize, and Sustain—are lean methodologies that promote efficiency and organization. 5S audit scorecards are tools that help implement these principles in the workplace, ensuring a clean and organized environment. A well-organized workspace directly contributes to better quality control by reducing errors, streamlining processes, and improving safety.

Using 5S audit scorecards, manufacturers can regularly assess and improve their work areas. For example, "Sort" can be integrated into checklists to ensure unnecessary items are removed, while "Shine" checks can maintain cleanliness. "Set in Order" ensures tools and materials are properly arranged, and "Standardize" helps maintain consistent practices. "Sustain" encourages ongoing adherence to these standards. By incorporating these elements into audit checklists, manufacturers can enhance quality control and operational efficiency.

Continuous Improvement with Weever’s Solution for Audit Checklists

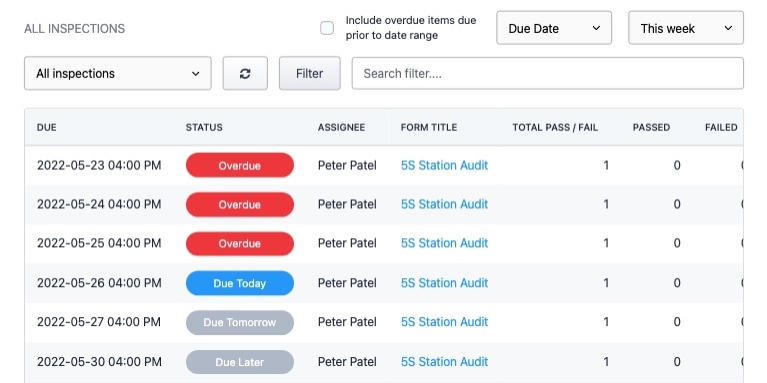

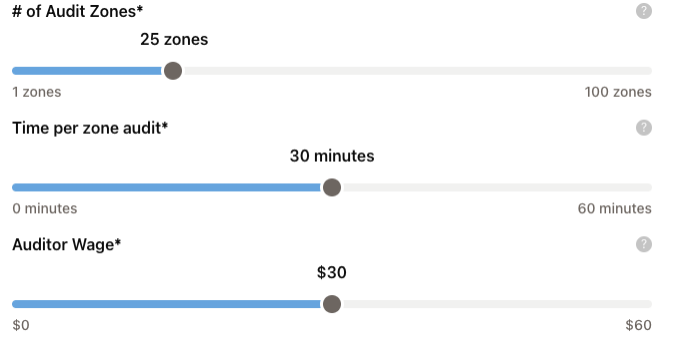

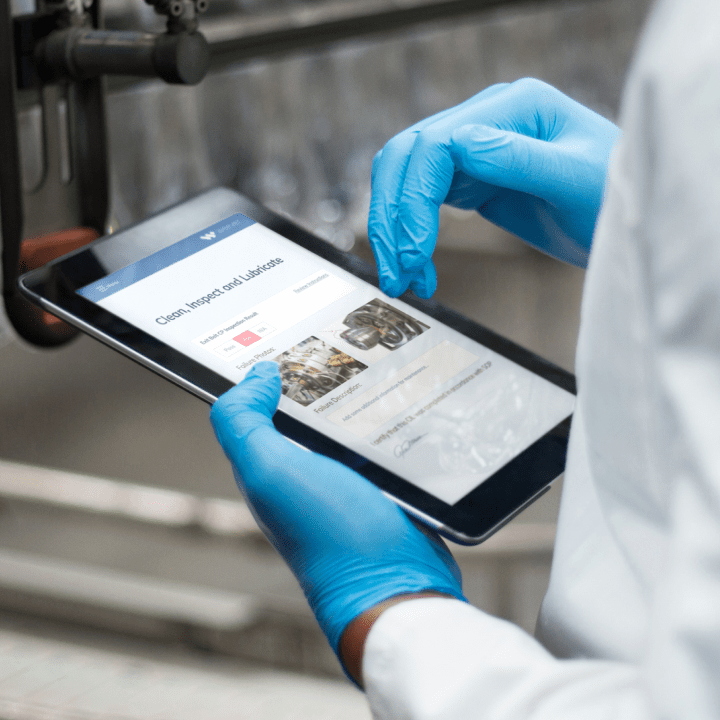

Continuous improvement is vital in manufacturing to stay competitive and maintain high-quality standards. Regular audits play a key role by providing ongoing feedback, identifying areas for enhancement, and ensuring processes are consistently optimized. Weever’s configurable audit checklists are designed to support this goal. These checklists can be easily adapted to evolving quality standards, allowing manufacturers to quickly respond to changes and implement improvements. By using Weever’s solution, manufacturers can ensure their audit processes remain relevant and effective, driving continuous improvement and maintaining excellence in their operations.

By using tools like near miss reporting software, predictive maintenance, and 5S audit scorecards, manufacturers can proactively address potential problems and maintain a clean, organized workspace. Weever’s configurable audit checklists adapt to evolving standards, providing ongoing feedback and driving continuous improvement.

Ready to enhance your quality control? Discover how Weever’s solutions can help your manufacturing operations maintain high standards and achieve excellence. Explore our offerings today and take the first step towards more efficient, reliable, and high-quality production processes.

Read our Ultimate Guide for 5S Auditing

Continue Learning about 5S

bandjlogo

Bell-logo-New

Canadian-Tire-Logo

Diageo-customer-logo

greyston-bakery-logo

hello-fresh-customer

marks-customer-logo

CSL_Limited_logo

monin-logo

Winland Food

Mars-logo-main

rise-baking-customer-logo

Rockwool-Customer-Logo-min

Sportcheck-customer-logo

unilever-customer-logo

walmart-logo-small

husqvarna-customer-logo

Ajinomoto_logo

Peet's_Coffee_logo

Royal-Canin-Logo