Simple 5S Implementation Action Plan

How does 5S work? What are the practical steps involved in a successful implementation?

5S Overview

5S Planning

5S Implementation

5S Auditing

5S Audit Digitization

FREE RESOURCEs

The 5S methodology is built on 5 easy to remember steps that have a natural flow to them as each step builds upon the success of the last. Although there are 5 principles, the methodology is best implemented in 3 Phases:

This article provides an overview for each phase. But before we get into the phases of your implementation plan, it is important to understand first what the 5S methodology is and why it is important.

What is 5S?

The 5S methodology is a systematic approach aimed at organizing a workspace for efficiency and effectiveness. It consists of five steps, each starting with the letter "S":

- Sort: Eliminate unnecessary items from the workspace, keeping only the essentials.

- Set in Order: Organize and arrange necessary items in a logical and accessible manner for easy retrieval and use.

- Shine: Clean the workspace regularly to maintain cleanliness and identify any issues or abnormalities.

- Standardize: Establish and maintain standardized work procedures to sustain the improvements made in the first three steps.

- Sustain: Develop a habit of maintaining the established standards and continuously improving the workspace.

This methodology is often applied in manufacturing, service industries, and various workplaces to streamline processes, reduce waste, and enhance productivity.

The Benefits of 5S

The 5S methodology can have a significant positive impact on many success factors for your business, including:

- Efficiency

- Safety

- Quality

- Employee Morale

- Cost Savings

- Continuous Improvement

Overall, 5S isn't just about tidying up; it's a systematic approach that contributes to operational excellence, safety, and a culture of continuous improvement within organizations.

3 Phase 5S Implementation Plan

Although the 5S methodology uses 5 "S" principles to structure how workstations are optimized, the implementation of 5S is actually comprised of 3 unique phases:

PHASE 1: PLAN

Ensure you have everything in place before moving forward.

Before embarking on your 5S journey its important to have the buy-in of all the key stakeholders in affected departments - production, safety, maintenance, and quality.

Build a core cross-departmental team of 5S champions from that you can leverage to help brainstorm how best to proceed based on the specifics of your plant.

Remember that this team will be responsible for not only organizing your 5S program, but also encouraging others to participate, so be sure to select managers that are credible and experienced leaders interested in guiding others through organizational change.

Build a Business Case

Create a comprehensive implementation plan that is aligned with your organization's corporate strategic goals and provides an overview of resource requirements, potential benefits and Return on Investment (ROI). A solid business case is essential to "selling" your plan internally and attaining the budget allocation required for a successful implementation.

Frontline Staff Training

Once you have gained alignment, you can start implementing 5S by providing training to your staff to understand the system.

This may be followed up with one-day sessions with each employee or team to ensure they are on the same page as far as implementation is concerned. The best results for training usually occur by quickly reviewing the 5Ss and then executing a 5S on an actual workstation. Use small groups and ask for participation.

PHASE 2: OPTIMIZE

Optimize each workstation for efficiency and productivity.

The Optimization Phase is best executed over a 3 day "Blitz". The Blitz is where you work with operators and frontline staff to optimize workstations based on the first 3 “S” principles:

- Sort - Declutter to enable flow.

- Set in Order - Everything in its right place

- Shine - Dirty work environments are inefficient work environments.

Schedule a 3 day 5S action plan with your teams after basic training is completed.

You will probably want to stagger these days out to one per week over a 3 week period to allow for follow up items like ordering visual guide labels, new equipment and storage, or the right cleaning materials.

When executing each step you will take notes of the final optimized state, which will be used to establish and maintain the workstation moving forward.

Interested in learning more about Weever?

Sort (Day 1)

Declutter to enable flow.

It's very easy for unnecessary items to build up in workspaces and seriously inhibit the optimal manufacturing flow. This can lead to all sorts of issues including quality defects, safety hazards, unneccesary duplication of tasks, employee frustration and productivity concerns.

As a result, Day 1 of the blitz focuses on identifying and eliminating any items that are known to be unnecessary, hazardous or duplicated.

When sorting and decluttering using the 5S methodology, several considerations can help ensure an effective process:

- Necessity

- Frequency of Use

- Redundancy

- Purpose

- Safety and Compliance

- Future Needs

- Team Input

Set in Order (Day 2)

Everything in its right place.

Once all the clutter has been removed during Day 1 (Sort), your team can get started on finding the ideal spot for tools, materials, and equipment.

The priority for the Set in Order step is efficiency - how can you organize work spaced to reduce wasted time and energy looking for equipment and other critical items. Consider the following when optimizing work areas:

- Evaluation - Complete the evaluation of the tagged items from Day 1. If the item is critical, find a new home for it during Set in Order. If the item hasn’t been used in the prior week, move it to your central storage location to reduce clutter.

- Appropriate Storage - New areas in the workplace may be required for specific items, such as hanging wall or modular storage.

- Visual Identification - Label all storage so that once a tool or item is removed it's easy to figure out how to put it back correctly.

Log Book Documentation - You may also want to consider a log book to record the new storage location of items to avoid confusion and lost time in the following days.

Just like your Day 1 (Sort), remember to document your Set in Order efforts thoroughly using before and after photos and notes.

Shine (Day 3)

Dirty work environments are inefficient work environments.

The presence of dirt, dust, and leaked fluids all contribute to equipment failures and workplace hazards. Machine downtime and injuries are the ultimate result of a failure to keep workspaces clean, both of which can sap the productivity and profitability of your facility.

A 5S shine is far more than a quick sweep and dust.

The 5S Shine is closer to a full clean, inspect, and lubricate of your entire plant, similar to one you might find in a new autonomous maintenance program. Clean work environments have been proven to improve the operating efficiency of equipment, reduce workplace safety risks, and improve employee morale.

Completing a single day of Shine is a good start, but should be a never ending process. By elevating cleanliness standards you are not just making a cleaner workplace, you are making a cultural change and moving towards the ideals of continuous improvement.

Some “Shine” activities you may want to consider are:

- A thorough sweep or dust of all surfaces Removal of grease, rust and stains

- Simple repairs to surfaces and storage areas

- Replacement of equipment components experiencing wear-and-tear

- Tightening of bolts and screws

- Repainting floors, walls, and equipment

As always, take photos to document the before and after to help reinforce the value of your ongoing 5S efforts. Review and resolve any outstanding action items from your Sort and Set in Order days, and take an inventory of what went well and areas of improvement for your next round of 5S Days.

Read our Ultimate Guide for 5S Auditing

PHASE 3: NORMALIZE

Sustain efficiency gains and ensure improvements are implemented.

The final step in 5S is all about the all-important process of cultural change and maintaining the forward momentum of your new continuous improvement culture.

In order to do this, the 5S methodology requires 2 unique, yet associated, principles are executed:

- Standardize - Establish and maintain consistent procedures, practices and visual controls.

- Sustain - Create a systemized process to ensure all principles are adhered to moving forward.

Merging these principles into a singular phase emphasizes the interconnectedness of maintaining standardized practices and sustaining them over time, fostering a culture of continual improvement and stability within the workplace.

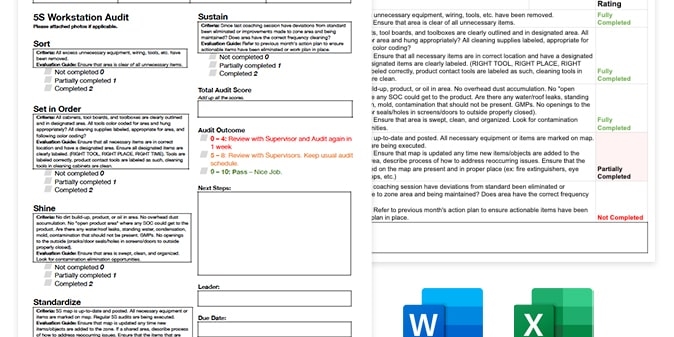

5S auditing involves assessing and evaluating the implementation and adherence to the 5S methodology within a workspace or organization. It's a systematic process that examines how well the Sort, Set in Order, Shine, Standardize, and Sustain principles are being followed.

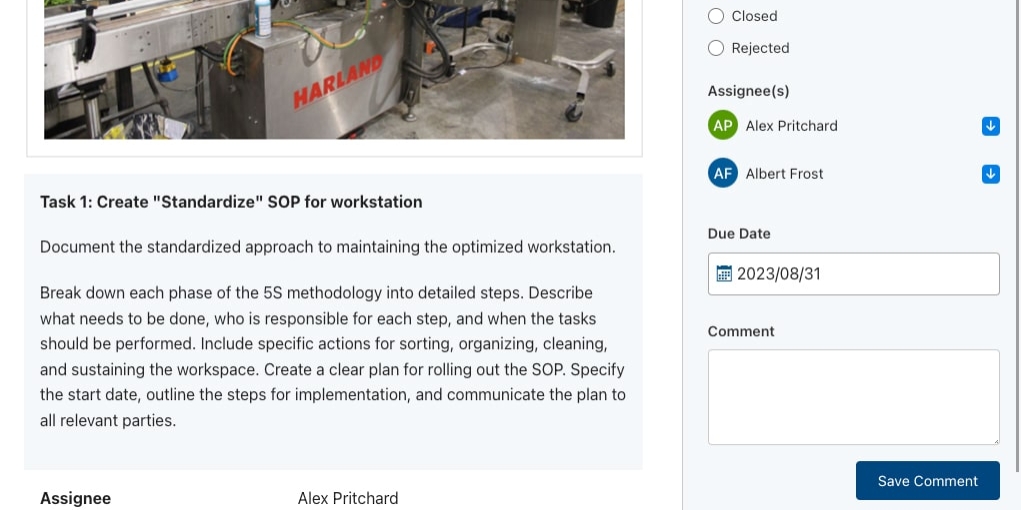

Standardize

The 5S Methodology is not a “one and done” type of process.

Although your first few 5S were based around specific days, the real value comes from codifying your gains as the new normal. The goal of standardization is to document, and implement actions, to maintain the new standards of cleanliness and efficiency your Blitz has created. This involves making 5S duties a part of your regular daily, weekly, and monthly duties.

You and your team undoubtedly learned a lot during the planning and optimization phases. Use that as a starting point to build a first draft of new 5S duties and make sure to get feedback from your staff and managers to ensure your list is complete and impactful.

Some examples of what you might do to standardize your 5S methodology include:

- Standardized Workstations

- Visual Standards

- Procedural Documentation

- Checklists and Guidelines

- Training Programs

- Performance Metrics

- Establish Communication Channels

- Continuous Improvement Plans

The goal of standardization in the 5S methodology is to create uniformity and consistency in work practices, processes, and visual controls across the organization, leading to increased efficiency, safety, and sustained improvements.

Sustain

Sustain efficiency gains and ensure improvements are implemented.

Sustaining 5S principles involves on-going efforts to maintain the organized, efficient, and standardized work environment established through the initial implementation.

Although Sustain is only one of the 5 principles of the 5S methodology, it encompasses 90% of the work. Sustain is the long-tail of 5S. And it is where the real results lie. It is also, conversely, the stage in which most 5S programs fail.

In order to realize the benefits of 5S, you must ensure principles are sustained using an efficient and effective 5S auditing program. This article outlines what sustain means, the benefits of an efficient auditing program and a simple and practical way to ensure success.

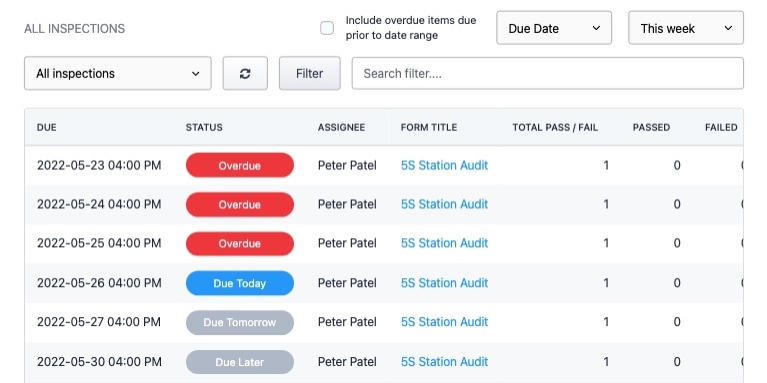

5S Auditing

Establishing a 5S auditing schedule is the most important factor to ensure workstation optimization is sustained. 5S audit schedules ensure standards are maintained, enhance employee engagement, and provide a means for improvements to be captured and implemented.

Implementing an effective 5S auditing program involves several practical steps to ensure a comprehensive assessment of the workspace:

- Establish Audit Criteria and Checklists

- Train Auditors

- Schedule Audits

- Conduct Audits

- Generate & Review Reports

- Implement Corrective Actions & Follow up Audits

- Celebrate Success and Recognition

By following these steps, organizations can systematically conduct 5S audits, drive improvements, and maintain a culture of continuous enhancement within their work environments.

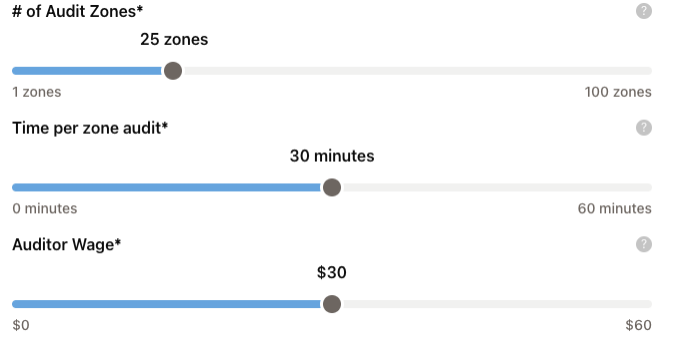

Digitizing 5S Auditing

The 5S methodology is a great way to build productivity and employee engagement from the ground up.

However, using paper forms and spreadsheets to manage the auditing process is a recipe for disaster. You should consider purpose-built 5S auditing schedules software to ensure success.

Continue Learning about 5S

bandjlogo

Bell-logo-New

Canadian-Tire-Logo

Diageo-customer-logo

greyston-bakery-logo

hello-fresh-customer

marks-customer-logo

CSL_Limited_logo

monin-logo

Winland Food

Mars-logo-main

rise-baking-customer-logo

Rockwool-Customer-Logo-min

Sportcheck-customer-logo

unilever-customer-logo

walmart-logo-small

husqvarna-customer-logo

Ajinomoto_logo

Peet's_Coffee_logo

Royal-Canin-Logo