Examples of Impactful Safety Observations in the Workplace

Safety observations in the workplace are critical for preventing accidents and fostering a culture of safety. At Weever Apps, we’ve seen firsthand how impactful these observations can be when done correctly.

In this post, we’ll explore real-world examples of effective safety observations and discuss techniques to make them more meaningful. We’ll also highlight common workplace hazards and show how proper observation can mitigate risks.

Common Workplace Safety Hazards: Identifying and Addressing Key Risks

Workplace safety stands as a paramount concern for organizations across industries. We at Weever Apps recognize several prevalent hazards that significantly impact employee well-being and operational efficiency. Understanding these dangers forms the foundation for creating a safer work environment.

Slips, Trips, and Falls: A Major Threat to Safety

Slips, trips, and falls represent a substantial portion of workplace injuries. Nonfatal occupational injuries associated with slips and falls are a significant concern in the United States. Common culprits include wet floors, loose carpeting, and cluttered walkways. To combat this issue, companies should:

-

Implement regular cleaning schedules

-

Use non-slip mats in high-risk areas

-

Ensure proper lighting throughout the workplace

Electrical Hazards: A Shocking Reality

Electrical hazards pose serious threats in many work environments. The Electrical Safety Foundation International highlights the gravity of this issue, reporting over 300 deaths and 4,000 injuries each year in U.S. workplaces due to electrical incidents. To mitigate these risks, organizations must:

-

Maintain proper insulation of electrical equipment

-

Conduct regular inspections of all electrical systems

-

Provide comprehensive safety training for employees (especially those working directly with electrical systems)

Ergonomic Issues: The Hidden Productivity Drain

Ergonomic problems often lurk unnoticed until they cause significant health issues. According to the Bureau of Labor Statistics, ergonomic injuries account for a third (33%) of all workplace injuries. To address this silent productivity killer, companies should:

-

Invest in ergonomic furniture and equipment

-

Provide training on proper posture and workstation setup

-

Encourage regular breaks and stretching exercises

Chemical Exposure: An Invisible Danger

Chemical hazards permeate numerous industries, posing risks that are often unseen but highly dangerous. The Occupational Safety and Health Administration (OSHA) estimates that over 32 million workers face potential exposure to chemical hazards. To protect employees from these risks, organizations must:

-

Ensure proper labeling of all chemicals

-

Maintain adequate ventilation in areas where chemicals are used or stored

-

Strictly adhere to safety protocols for handling and storage

-

Provide appropriate personal protective equipment (PPE) and train employees on its proper use

Identifying these common hazards marks only the beginning of a comprehensive safety strategy. The next crucial step involves implementing effective safety observation techniques to prevent accidents and foster a culture of safety. Tools like Weever Apps can streamline this process, making it easier for organizations to report, track, and address potential hazards before they escalate into incidents.

How to Improve Safety Observation Techniques

Safety observations become more effective with the right techniques. Let’s explore proven methods to enhance your safety observation practices.

Engage Employees in the Safety Process

Active engagement transforms workplace safety. Encourage all employees to participate in the observation process. This approach creates a sense of ownership and responsibility for safety across the organization.

A study conducted by Safety+Health magazine found that companies with engaging safety programs had a 70% lower rate of workplace accidents compared to those with low engagement. To boost engagement, implement a peer-to-peer observation program. This allows employees to learn from each other and reinforces safe behaviors throughout the workplace.

Document Observations Consistently and Thoroughly

Consistent documentation identifies trends and areas for improvement. Establish a standardized format for recording observations. Include the date, time, location, specific behaviors observed, and any immediate actions taken.

The Occupational Safety and Health Administration (OSHA) emphasizes that undocumented safety is considered non-existent. This underscores the importance of thorough record-keeping. Try to document both safe and unsafe behaviors to provide a comprehensive picture of workplace safety.

Focus on Both Safe and Unsafe Behaviors

A balanced approach to safety observations yields the most valuable insights. Record instances of exemplary safety practices alongside potential hazards. This comprehensive view helps to:

- Reinforce positive behaviors

- Identify areas for improvement

- Create a more accurate representation of workplace safety culture

Leverage Technology for Real-Time Reporting

Digital tools revolutionize safety observation practices. Modern platforms allow for real-time reporting and analysis of safety observations. This immediacy enables quick identification and resolution of potential hazards.

A survey by EHS Today found that organizations using digital safety management tools reported a 20% increase in the number of safety observations recorded (compared to those using paper-based systems). Real-time reporting also facilitates faster communication of critical safety information across teams and locations.

These techniques significantly enhance safety observation practices. The goal extends beyond data collection; it’s about using that data to drive meaningful improvements in workplace safety. The next section will explore specific examples of impactful safety observations, demonstrating how these techniques translate into real-world safety improvements.

Real-World Safety Observations That Save Lives

Safety observations prevent accidents and save lives. This chapter explores concrete examples that showcase the power of effective safety observations.

Near-Miss Reporting: A Proactive Approach

Near-miss incidents provide opportunities to improve workplace safety. Near misses are important indicators that can help prevent future accidents in the workplace. A chemical plant in Texas implemented a robust near-miss reporting system, which reduced recordable incidents by 50% within a year. The plant created a non-punitive environment where workers reported close calls without fear.

To achieve similar results, companies should:

- Set up an easy-to-use reporting system

- Train employees on near-miss identification

- Analyze near-miss data to spot trends and implement preventive measures

PPE Compliance: Beyond Basic Wear

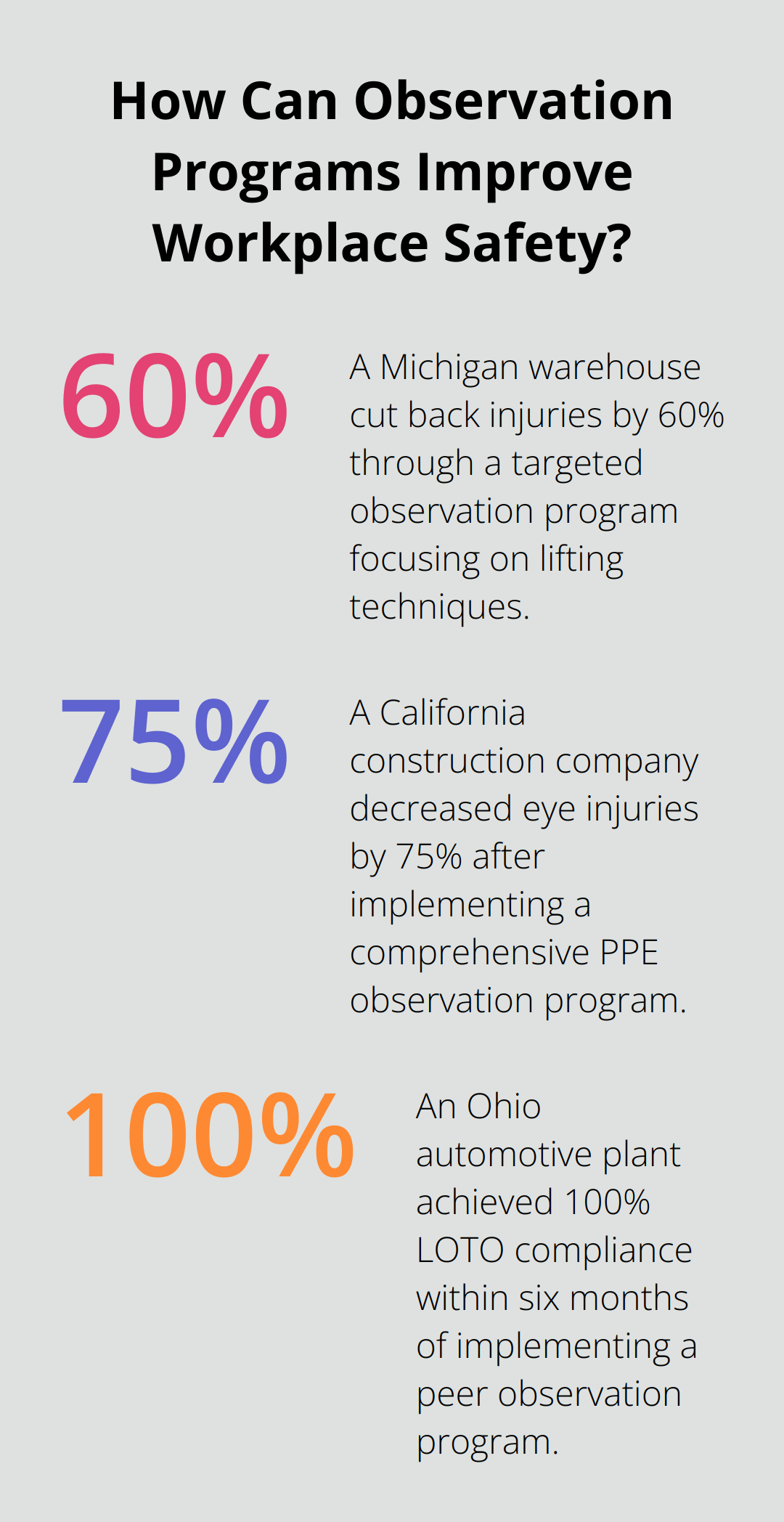

Proper use of Personal Protective Equipment (PPE) involves more than just wearing it. A California construction company decreased eye injuries by 75% after implementing a comprehensive PPE observation program. The program ensured workers wore the right type of safety glasses for each task and that they fit properly.

Effective PPE observations should include:

- Regular checks on PPE condition

- Verification of PPE appropriateness for specific tasks

- Observations on PPE wear and adjustment

Material Handling: Attention to Detail

Safe material handling practices reduce workplace injuries significantly. A Michigan warehouse cut back injuries by 60% through a targeted observation program focusing on lifting techniques. The program went beyond basic advice, training observers to look for specific body positions, load assessment, and use of mechanical aids.

Key aspects of effective material handling observations include:

- Checks for proper use of lifting aids (e.g., dollies and forklifts)

- Observations of load assessment before lifting

- Monitoring of team lifting practices for heavy or awkward items

Lockout/Tagout: Life-Saving Procedures

Compliance with Lockout/Tagout (LOTO) procedures prevents serious injuries and fatalities. An Ohio automotive plant achieved 100% LOTO compliance within six months of implementing a peer observation program. The program’s success stemmed from its focus on positive reinforcement and immediate feedback.

Effective LOTO observations should include:

- Verification that all energy sources are identified and properly locked out

- Checks that tags are clearly visible and contain all necessary information

- Observations of the testing process to ensure zero energy state

These real-world examples demonstrate the tangible impact of well-implemented safety observation programs. They highlight that success depends on specificity, consistency, and a focus on positive reinforcement.

Final Thoughts

Safety observations in the workplace are essential for creating a thriving, safe work environment. These practices save lives, boost productivity, and reduce costs associated with workplace injuries. A proactive safety culture, built on consistent and thorough observations, improves overall employee morale and engagement.

The future of safety management involves leveraging technology to enhance observation practices. Digital tools streamline the process of recording, analyzing, and acting on safety data. They enable real-time reporting and facilitate quick responses to potential hazards.

At Weever Apps, we’ve developed a Connected Worker platform that supports comprehensive safety programs, including Behavior Based Safety Observations. Our platform makes it easy to capture data, automate workflows, and gain cross-team visibility. Every observation has the potential to prevent an accident and save a life.