How elevated safety increases employee engagement at manufacturing organizations

Elevated safety can have a positive impact on employee engagement at manufacturing organizations in several ways:

Builds Trust

When employees feel safe at work, they develop a sense of trust towards their employers. They feel valued and supported, and this can create a positive relationship between employees and management. This trust can foster an environment of transparency and open communication, which can increase employee engagement.

Boosts Morale

A safe work environment can boost employee morale, as it shows that the company cares about their well-being. When employees feel that they are valued, they are more likely to be engaged and committed to their work.

Reduces Stress

Workplace injuries and accidents can cause significant physical and emotional stress for employees. By prioritizing safety measures, organizations can reduce the risk of accidents and injuries, which can lead to a more positive work environment and reduced stress levels.

Increases Productivity

Safe working conditions can also lead to increased productivity. When employees feel safe, they can focus on their work without worrying about potential hazards. This can lead to higher levels of concentration and increased productivity.

Improves Retention

Employees who feel safe and supported are more likely to stay with the organization. This can reduce turnover rates and help organizations retain their most valuable employees.

How Weever can help

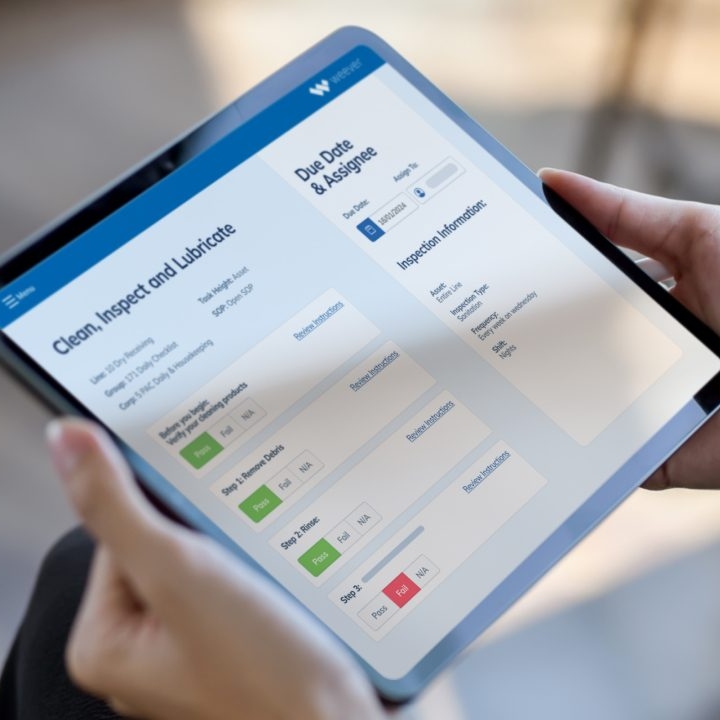

Weever provides digital tools that unlocks your team's experience and insights, simplifies decision-making, and removes barriers that are hindering them from achieving their full potential.

Weever guides your team through digital workflows, and empowers them to easily capture their observations, insights, and improvement ideas.

The incredibly valuable human dimension of data capture, fuelled by instinct, experience and intuition, is something that is otherwise difficult to harness and action (and impossible when using paper).

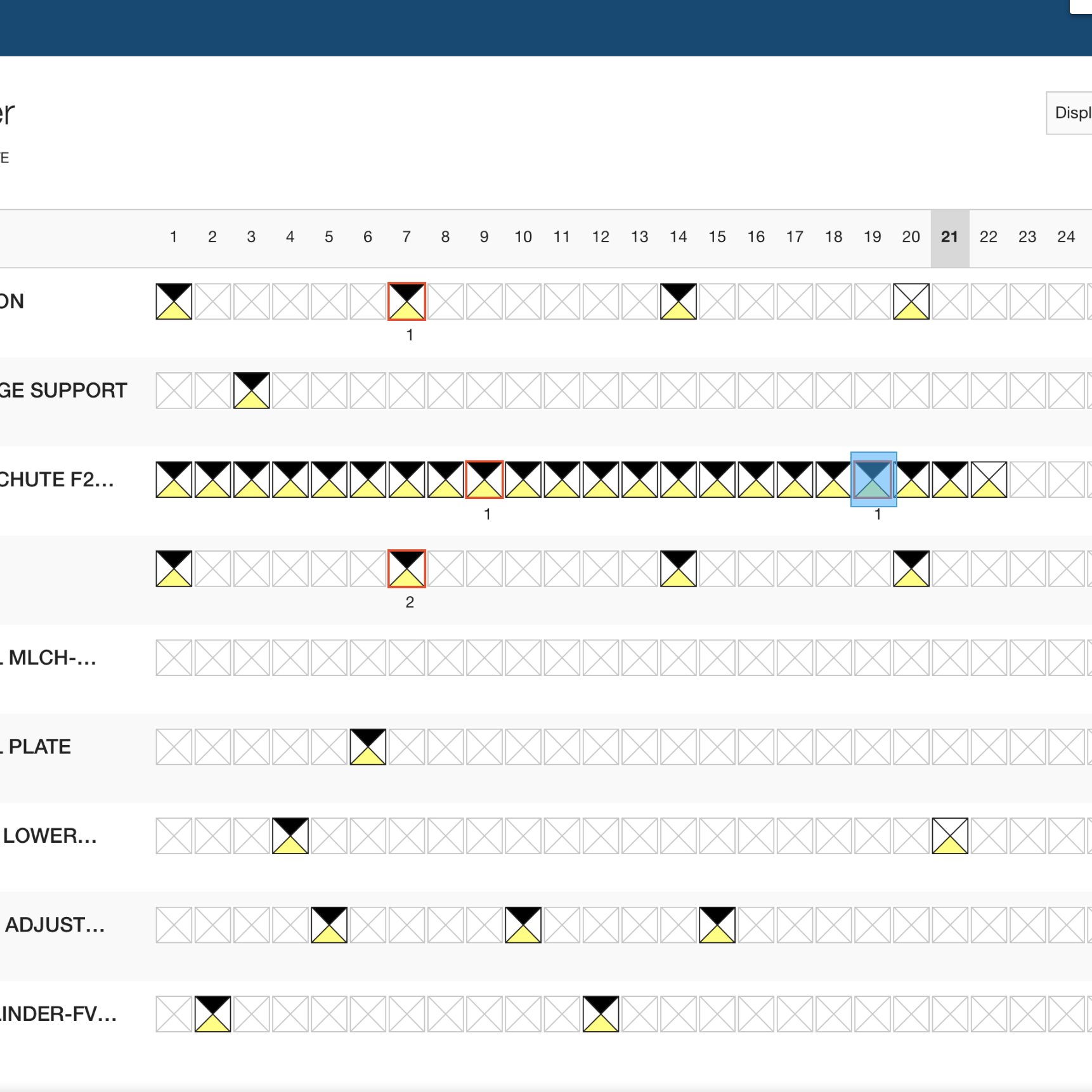

Once captured, Weever transforms people-led data into actionable metrics and real-time insights that allow you to drive your organization forward.

Your employees, in turn, can see and feel the tangible impact that they are making – unlocking the success that comes through an empowered team.

Frontline Employee Engagement is a measure of how invested your frontline employees are in the growth and prosperity of your organization. If you change their investment level by enabling them, energizing them, and empowering them, you will reap the benefits of increased engagement.

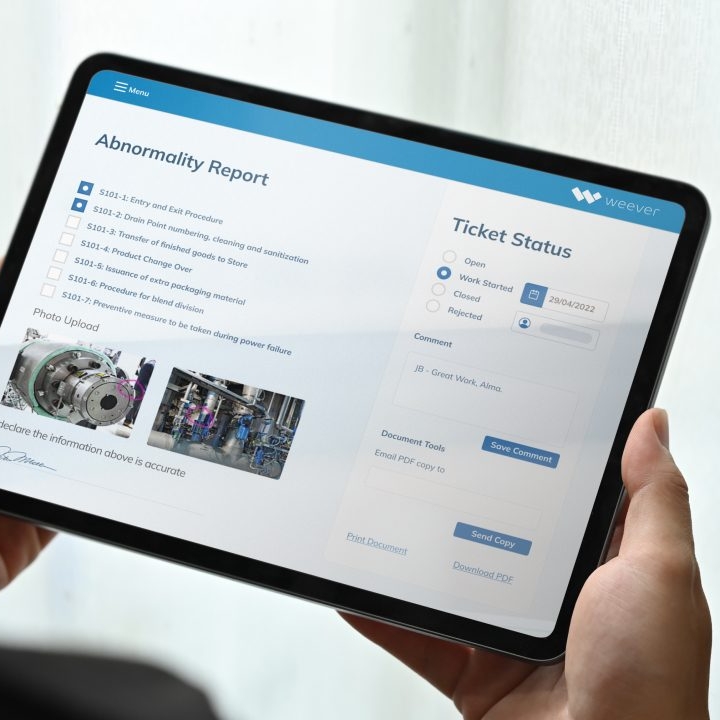

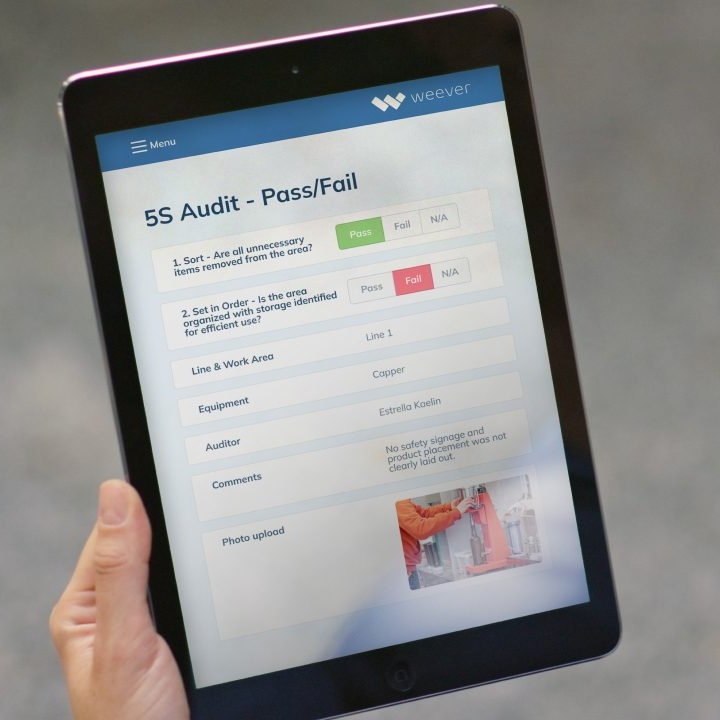

- Empower your staff with “bottom up” Operational Excellence tools. Allow staff to understand the value your organization is manufacturing and how it is delivered so that they can correct issues autonomously. Staff can submit suggestions, observations, and abnormality reports and watch the progress of them into site initiatives and improvement projects.

- Energize your staff with personal goal tracking, gamification and automated reward points that they can redeem in your personalized rewards marketplace. Broadcast result KPIs and celebrate wins to keep staff engaged.

- Enable your staff with instant access to modern software that is just as focused on Operational Excellence as it is on Employee Engagement. Weever makes it easy to collect data, track projects and view reports while staff can also review leaderboard, point totals and redeem rewards - all in one place.

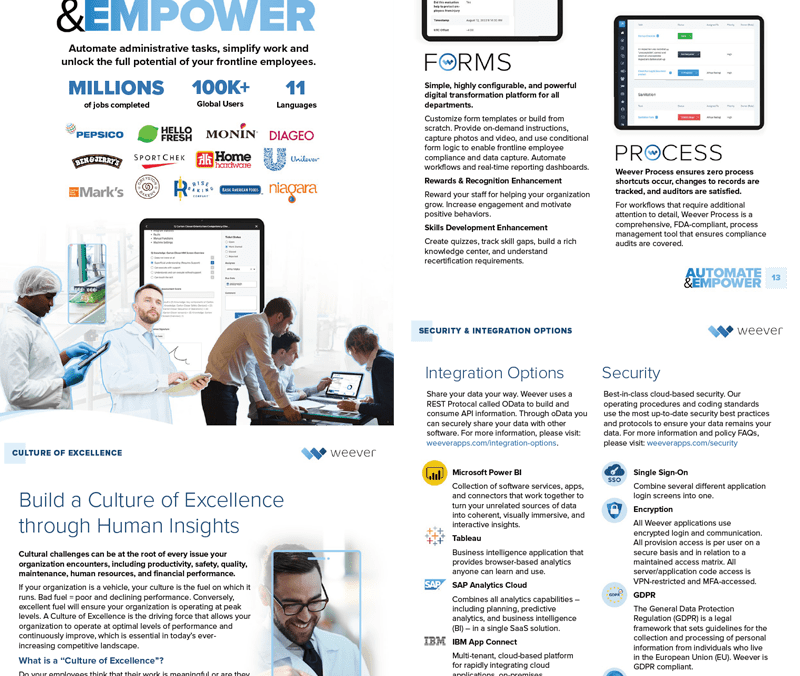

Frontline Employee Engagement Ultimate Guide

Everything you need to know about how to Build a Culture of Excellence by increasing the engagement of your frontline employees.

Everything you need to know about how to Build a Culture of Excellence by increasing the engagement of your frontline employees.

Learn about the Platform.

Download the brochure to get all the details about how Weever works.

Learn more about Weever

Weever is a comprehensive operations management platform that is used to automate safety, quality, maintenance, production, compliance, continuous improvement and training operational requirements.