Digitization Mavericks

Unlock the Potential of Your Factory

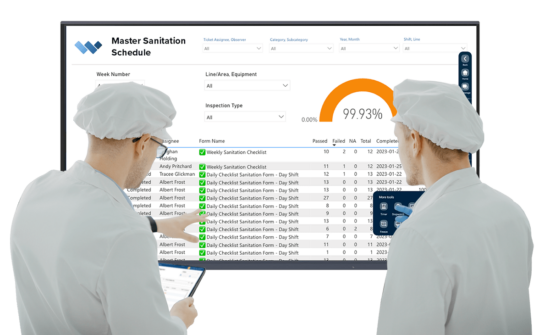

Embrace the Paperless Revolution for Enhanced Productivity, Visibility, and Compliance. In the era of digital transformation and automation, factories have experienced remarkable technological advancements. Yet, astonishingly, many factories still rely on mountains of paper to capture data, manage workflows, and generate KPI reports on the factory floor.

Read MoreThe Costs of Non-Compliance for Food Manufacturers

The cost of non-compliance for FDA violations can vary depending on several factors, including the nature and severity of the violation, the scale of the operation, and the history of compliance of the manufacturer. Some potential costs associated with FDA violations for food manufacturers may include:

Read MoreProactive Safety: How Walmart Utilizes Weever to Drive Safety Excellence

Discover why Kody has found Weever, an innovative operations management software platform specializing in Food and CPG manufacturing, to be an indispensable tool for managing Walmart’s BBSO program.

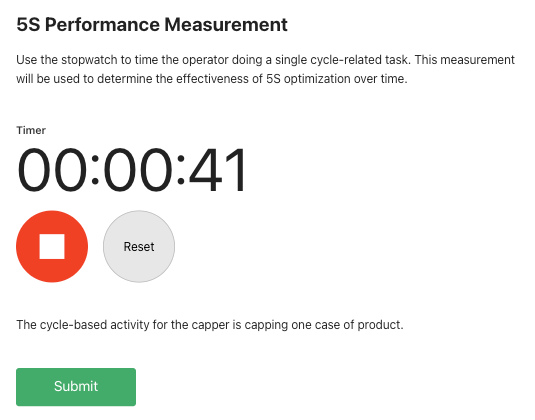

Read MoreMeasure the Real Impact of your 5S Audits with Cycle-based Activity Timing

Cycle time is the duration of one production cycle, and it can be used as a metric to identify improvement opportunities in a manufacturing process. By measuring cycle time, managers can identify bottlenecks, waste, and inefficiencies, and develop strategies to improve the process.

Read MoreTop 5 Frontline Employee Engagement Best Practice

Are you tired of slogging through your workday, feeling unfulfilled and disconnected from your organization? Do you wish you could be part of a culture of excellence that inspires innovation, collaboration, and engagement?

Well, look no further! We have compiled some of the best practices we’ve seen in our 10 years of working with organizations around the world to help you build a culture of engagement and achieve amazing results.

Read MoreHow to increase Employee Engagement by focusing on Ease and Usefulness

According to numerous studies Continuous Improvement program participation can be predicted by the amount of intention employees have to participate, which is inflences by Ease and Usefulness of participation.

Read MoreWhat is Daily Management System (DMS)and how does it help manufacturers?

The Daily Management System (DMS), also known as Daily Direction Setting (DDS), is a framework for managing operational performance in manufacturing organizations. It is a structured approach to managing day-to-day operations that focuses on continuous improvement and waste reduction.

Read MoreHow skill development increases frontline employee engagement in manufacturing organizations

Investing in employee skills and training can have numerous benefits for manufacturing organizations, including increased employee engagement, motivation, retention, productivity, and quality.

Read MoreHow elevated safety increases employee engagement at manufacturing organizations

Elevated safety can have a positive impact on employee engagement at manufacturing organizations by building trust, boosting morale, reducing stress, increasing productivity, and improving retention.

Read MoreHow does workflow automation increase collaboration in a manufacturing facility?

Workflow automation can increase collaboration in a manufacturing facility in several ways. By automating the flow of information between different systems and teams, manufacturers can improve communication and collaboration, leading to better decision-making and more efficient operations.

Read More