Digitization Mavericks

5S Standardize Implementation

Step-by-step guide to ensuring processes, procedures, and practices adhere to a defined standard, facilitating consistency and predictability.

Read More5S Shine Implementation

Among the 5S five pillars, Shine holds a crucial position in maintaining cleanliness, safety, and functionality within workstations. Let’s delve into the specifics of this essential step and explore how it drives the 5S methodology toward excellence.

Read More5S Set in Order Step Implementation

Set in Order focuses on arranging essential items in a logical and efficient manner, optimizing the workspace layout for improved accessibility, safety, and workflow.

Read More5S Sorting Implementation

The first step in 5S workstation optimization, Sorting identifies and removed unnecessary items based on your sorting criteria.

Read MoreHow to Train Frontline Staff on 5S

How to Train Frontline Staff on the Essentials of 5S Principles Best practices for efficiently providing frontline staff with a general overview of 5S. 5S Overview 5S Planning 5S Implementation 5S Auditing FREE RESOURCEs In any manufacturing facility, the frontline staff plays a crucial role in upholding efficiency, safety, and productivity. One effective way to…

Read More5S Auditor: How to Train Them Efficiently

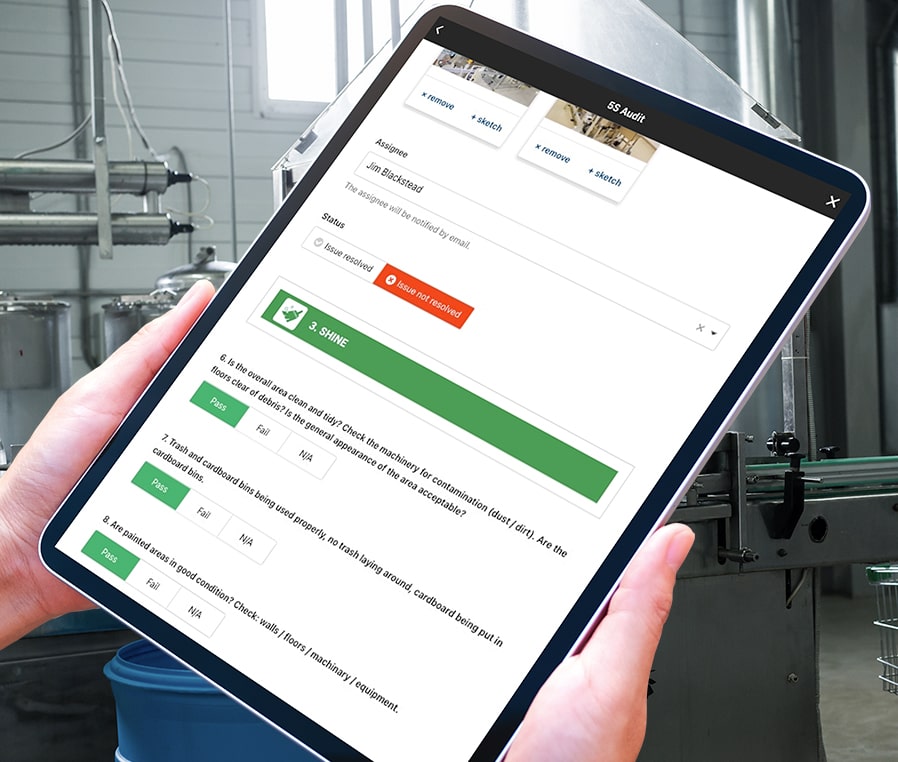

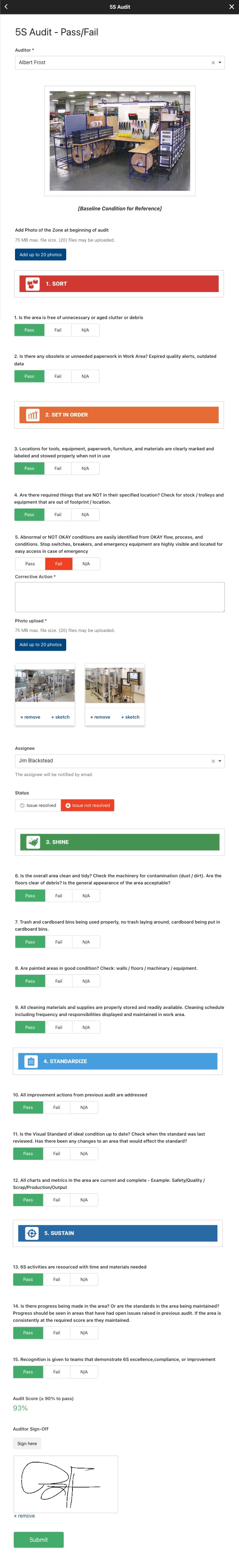

5S auditors need to be trained first and foremost on the principles of 5S. They should also receive some training on how to conduct effective audits as well as how to use the 5s auditing software.

Read MoreHow to establish 5S Audit Criteria

For checklists to be effective, it is important to understand your audit criteria, which serves as the guidelines or standards against which the workspace will be evaluated.

Read MoreHow to create a 5S Audit Checklist

Practical guide to creating simple and powerful 5S audit checklists to ensure 5S principles are sustained and improvement opportunities are captured.

Read More5S Sustain Implementation

Sustaining 5S workstation optimization requires a systematic approach, incorporating scheduled audits, proactive corrective actions and detailed reporting. Learn everything you need to know to sustain and improve workstation productivity.

Read MoreTop 5S benefits for manufacturing companies

The 5S methodology can have a significant positive impact on many success factors for your business, including efficiency gains, enhanced safety and quality, improvements to employee engagement and moral, cost savings and continuous improvement.

Read More