Employee Engagement

Top 5 Frontline Employee Engagement Best Practice

Are you tired of slogging through your workday, feeling unfulfilled and disconnected from your organization? Do you wish you could be part of a culture of excellence that inspires innovation, collaboration, and engagement?

Well, look no further! We have compiled some of the best practices we’ve seen in our 10 years of working with organizations around the world to help you build a culture of engagement and achieve amazing results.

Read MoreHow to increase Employee Engagement by focusing on Ease and Usefulness

According to numerous studies Continuous Improvement program participation can be predicted by the amount of intention employees have to participate, which is inflences by Ease and Usefulness of participation.

Read MoreWhat is Daily Management System (DMS)and how does it help manufacturers?

The Daily Management System (DMS), also known as Daily Direction Setting (DDS), is a framework for managing operational performance in manufacturing organizations. It is a structured approach to managing day-to-day operations that focuses on continuous improvement and waste reduction.

Read MoreHow skill development increases frontline employee engagement in manufacturing organizations

Investing in employee skills and training can have numerous benefits for manufacturing organizations, including increased employee engagement, motivation, retention, productivity, and quality.

Read MoreHow elevated safety increases employee engagement at manufacturing organizations

Elevated safety can have a positive impact on employee engagement at manufacturing organizations by building trust, boosting morale, reducing stress, increasing productivity, and improving retention.

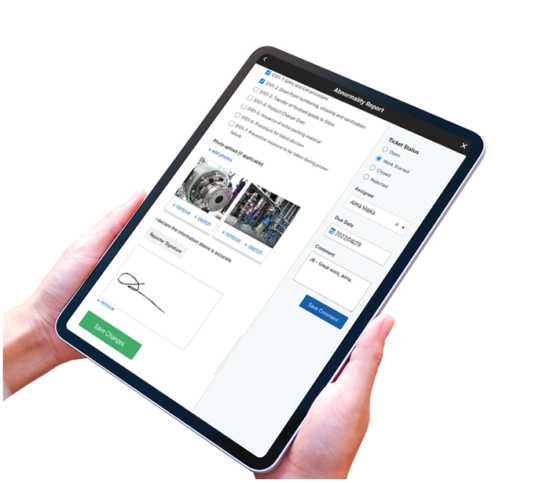

Read MoreTop 5 Benefits of Digitizing your Autonomous Maintenance Program

If you using paper forms, there are many benefits you can realize by switching to software, such as increased adoption, real-time escalation, on-demand instruction, rich data, and reducing the burden of administration.

Read MoreWhy you should be executing Autonomous Maintenance and you should start today

Autonomous Maintenance (AM) is the most important pillar within the Total Productive Maintenance (TPM) methodology because it provides maintenance teams with the data and the time to make the other pillars happen. There are numerous benefits that can be realized with a well managed AM program. Here are the top benefits that we have witnessed while working with our customers.

Read MoreWhat are the types of abnormality categories and why should I use them?

How to use standard abnormality report categories and subcategories to create insight-driven reporting. Here are the recommended categories and subcategories as well as some helpful considerations for your frontline staff to aid next steps.

Read MoreBetter Continuous Improvement Data through Digital Transformation

Juan is a process engineer with a decade of experience helping CPG manufacturers implement continuous improvement processes. In his latest role he found himself working at a small division of a large national food manufacturer that was just taking its first steps towards lean manufacturing and operational excellence.

Read MoreMonin saves 3-4 hours each day with Weever

Monin was drowning in paper and looking for a system that would ensure compliant workflows and automate KPI reporting insights to inform continuous process improvement, all without overwhelming operators.

Read More