Employee Engagement

Why digitize factory operations?

Weever is Operational Excellence Software that empowers the pursuit of perfection by enhancing operational visibility, collaboration and productivity in quality, maintenance, safety and production. This article reviews the following topics: Cost Savings Real-time Visibility Automation Simplicity & Structure Compliance There are countless benefits to transitioning paper and spreadsheet-based processes to a digital framework. Paper has…

Read MoreThe Problem with Paper

Weever is Operational Excellence Software that empowers the pursuit of perfection by enhancing operational visibility, collaboration and productivity in quality, maintenance, safety and production. This article reviews the following topics: Stagnant Waste Time Errors Inconsistent Why do paper forms limit factory operations and continuous improvement? Manufacturers come in a lot of different shapes and sizes.…

Read MoreThe 3 EEEs of Sustainable Frontline Employee Engagement

Are you part of the 71% of executives that say Employee Engagement is critical to the company’s success?

In order to foster a culture of excellence you need to increase engagement of your employees by ensuring they are Empowered, Energized and Enabled.

How to stimulate positive change in your manufacturing facility during a pandemic.

3 tips for enhancing continuous improvement during COVID-19 and beyond. COVID-19 is a global pandemic and there are signs that this virus may change the way we live and work into the future. Many of our customers are food manufacturers who are mandated to continue production. They are taking precautions to keep their staff as…

Read MoreSocial Distancing within the Factory

Most manufacturing is an essential service and must continue during the outbreak of COVID-19. However, that does not necessarily mean that staff cannot socially distance within the factory walls. Manufacturing requires staff to coordinate operations within a defined space. There are many ways that staff interact with each other including: Data Collection: Most factories still…

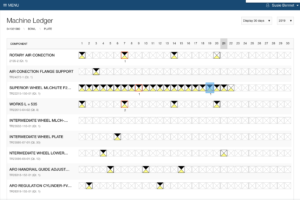

Read MoreUnderstanding the Machine Ledger

The Machine Ledger is used in World Class Manufacturing to better understand machines, sections, assemblies, and components so that maintenance teams can more effectively predict failures and plan preventive maintenance activities.

Read More4 ways to reduce waste from your Continuous Improvement process

Kaizen is the process of incrementally improving processes by eliminating “waste”. Small improvements over time can have a huge impact on productivity and the bottom line. Waste can come in many forms, including unnecessary inventory, physical movements and scrap. Kaizen only works if everyone is involved, which includes top management and, more importantly, the workers…

Read More3 ways to get operators more involved in maintenance

Creating an autonomous maintenance program is a great way to increase machine up-time and focus on more strategic machine maintenance programs. Getting the operators involved in clean, inspect and lubricate (CIL) maintenance task keeps the line running smoother. Operators learn a bit more about what is “under the hood” of each machine, which makes them…

Read More5 ways to optimize your Time-Based Maintenance (TBM) program

5 ways to optimize your Time-Based Maintenance (TBM) program Andy Pritchard | January 3 2022 | 5 min read Time-Based Maintenance (TBM) Time-based maintenance (TBM), as the name suggests, is maintenance performed on equipment based on a schedule. TBM maintenance is planned maintenance, as it must be scheduled in advance, which means it can…

Read MoreWhy ERPs are not Maintenance Management Software

Enterprise Resource Planning (ERP) software is great at what it does. Unfortunately, that does not include being an intuitive data capture and workflow tool for your staff. Some of our customers use SAP, Oracle or Netsuite, to manage their business costs, inventory, purchasing, etc. These ERPs are also supposed to be used for maintenance to…

Read More