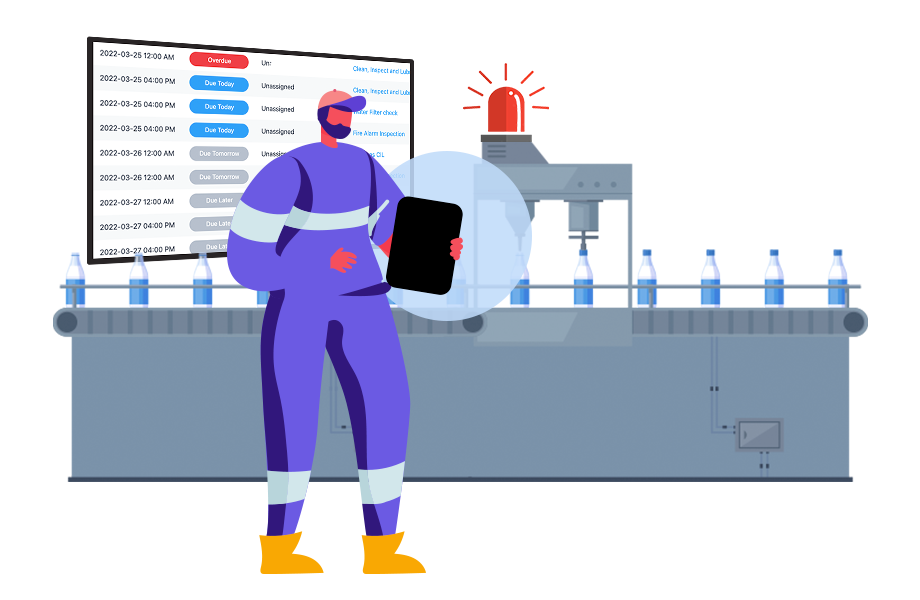

Never Miss Another Task.

"Set it and forget it" with Weever Inspections. Create and manage schedule assigned to machine and users. Spend less time on administration and ensure flawless execution.

bandjlogo

Bell-logo-New

Canadian-Tire-Logo

Diageo-customer-logo

greyston-bakery-logo

hello-fresh-customer

marks-customer-logo

CSL_Limited_logo

monin-logo

Winland Food

Mars-logo-main

rise-baking-customer-logo

Rockwool-Customer-Logo-min

Sportcheck-customer-logo

unilever-customer-logo

walmart-logo-small

husqvarna-customer-logo

Ajinomoto_logo

Peet's_Coffee_logo

Royal-Canin-Logo

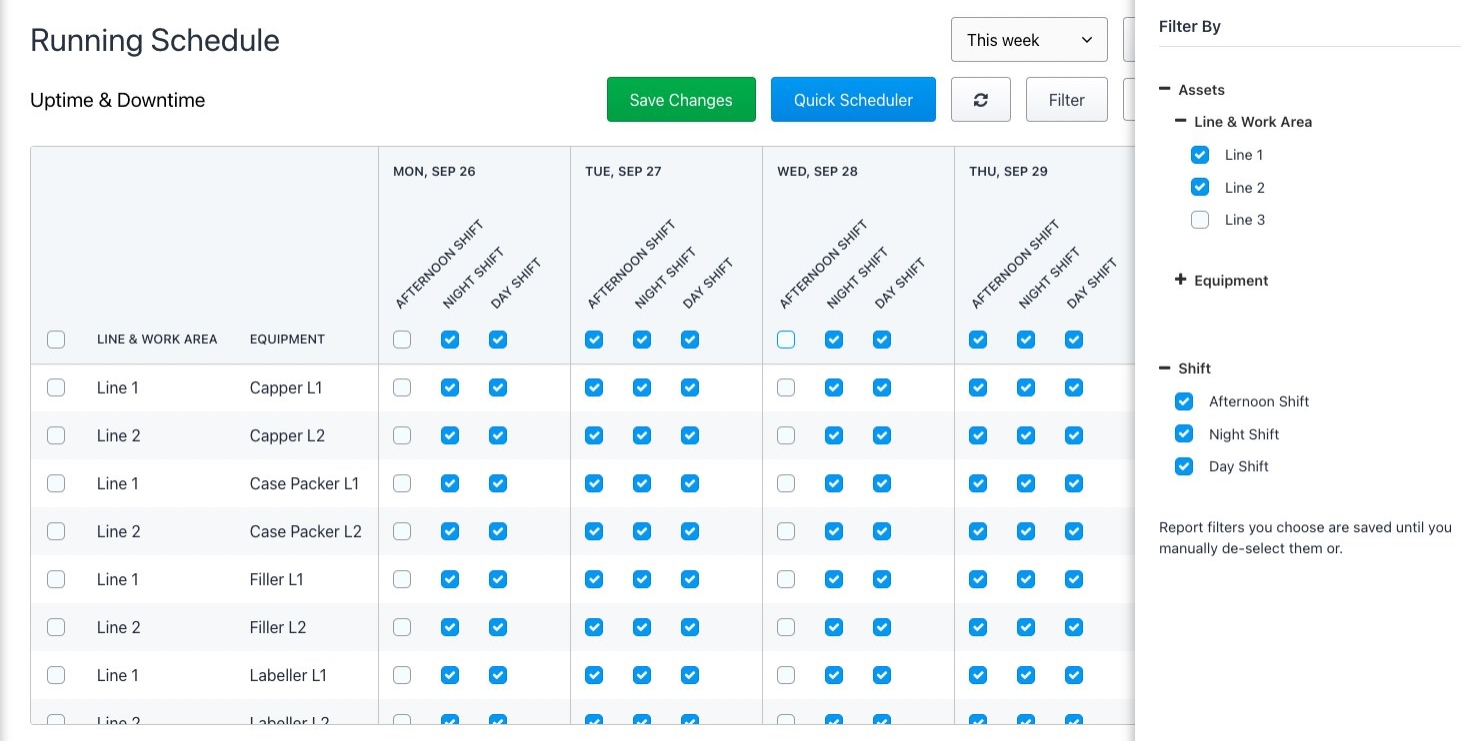

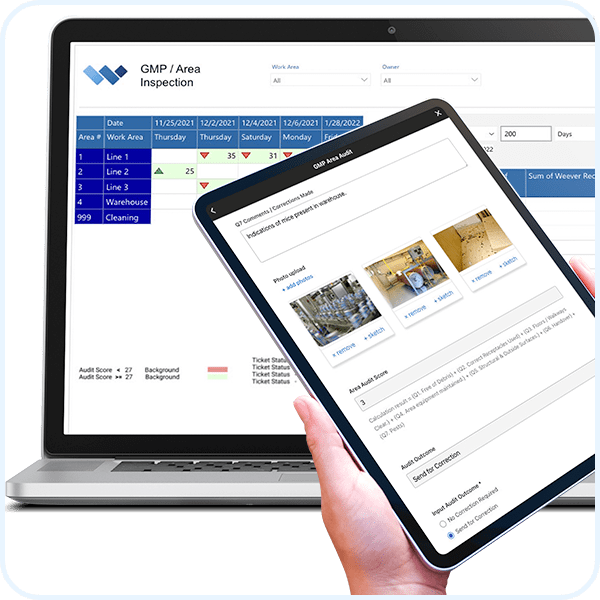

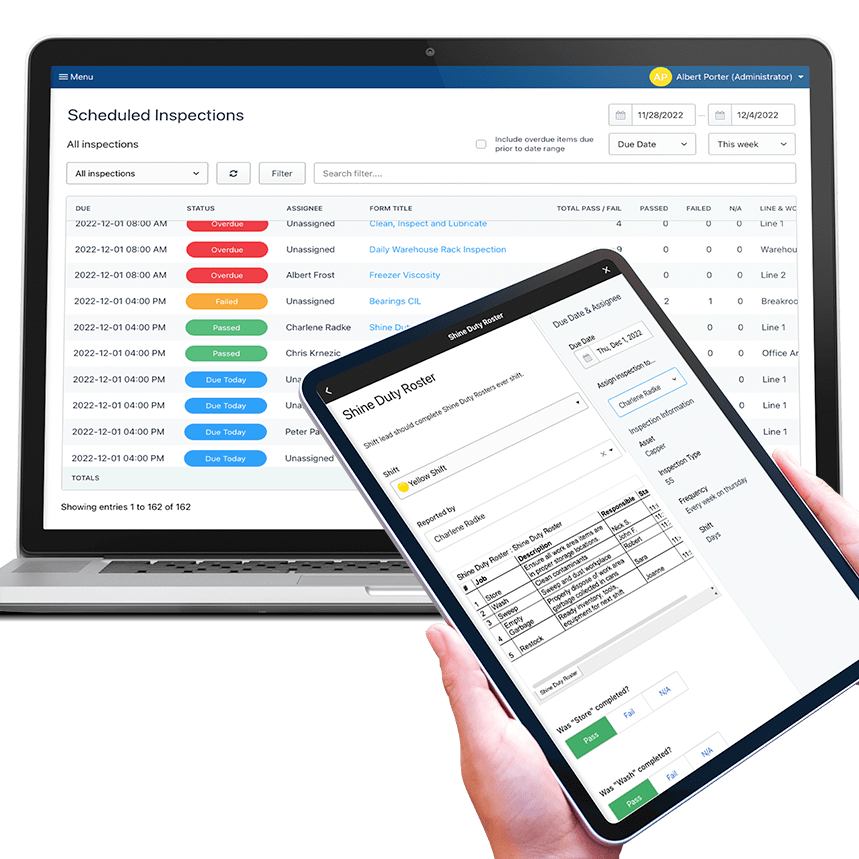

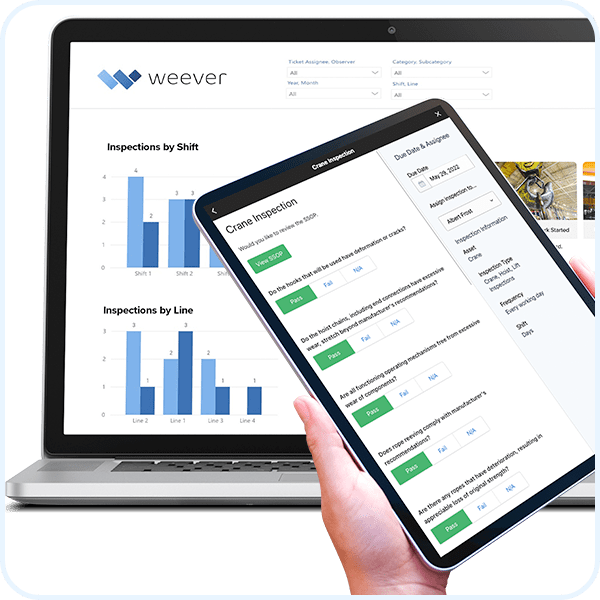

Ensure Schedules are Consistently Followed.

Manage a comprehensive schedule and understand instantly if any were missed or failed.

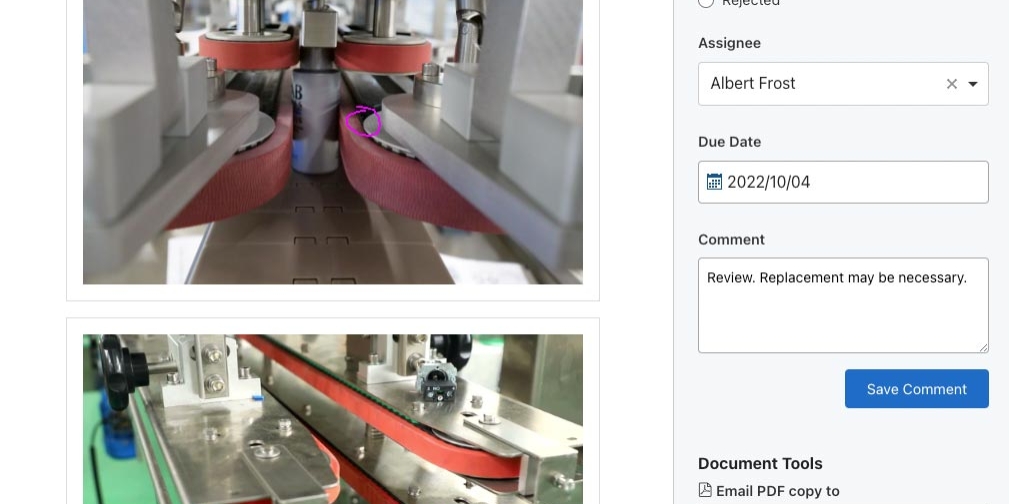

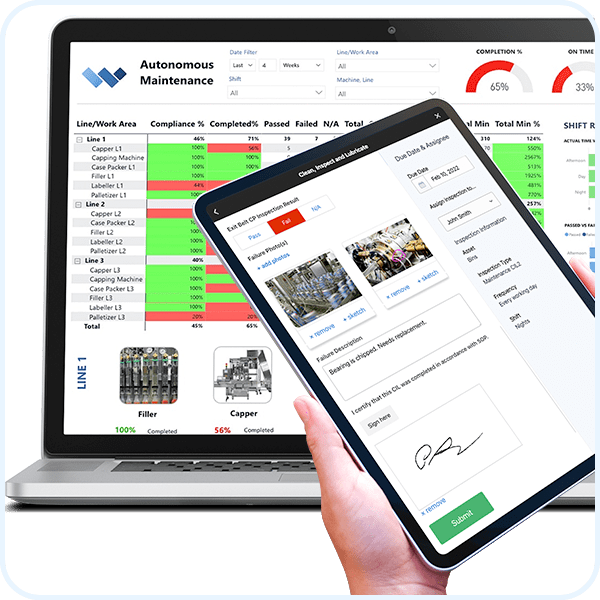

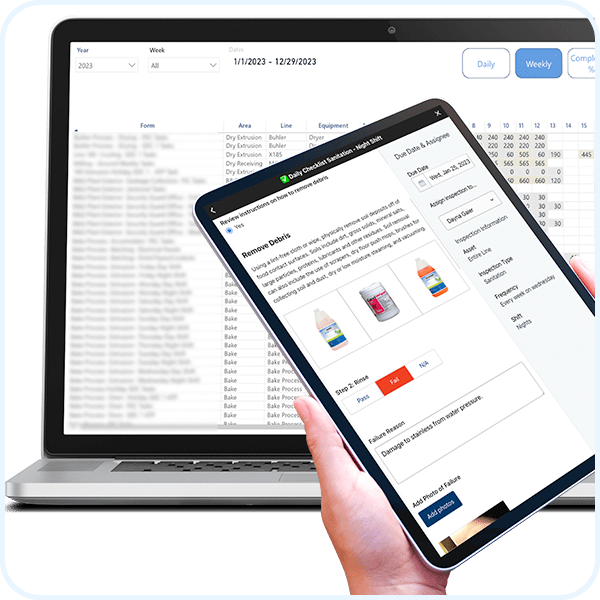

Automate Failure Workflows

Tickets are automatically generated for evaluation and action when an inspection “fails”.

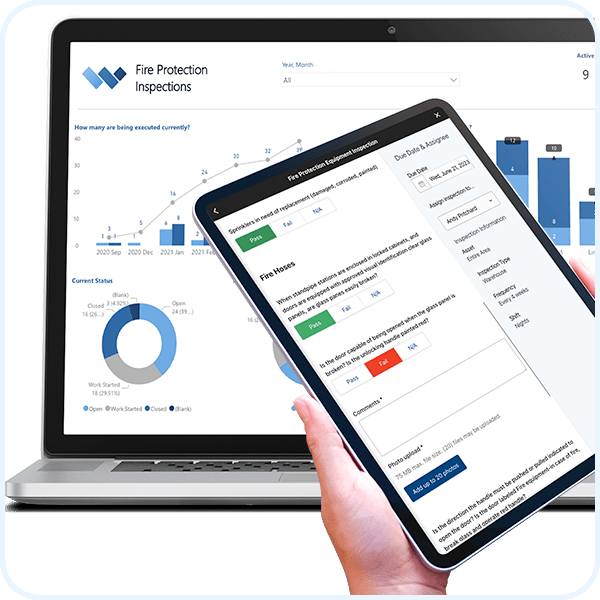

Generate Rich, Insight-Driven Reports

Automatically update stunning insight-driven reports.

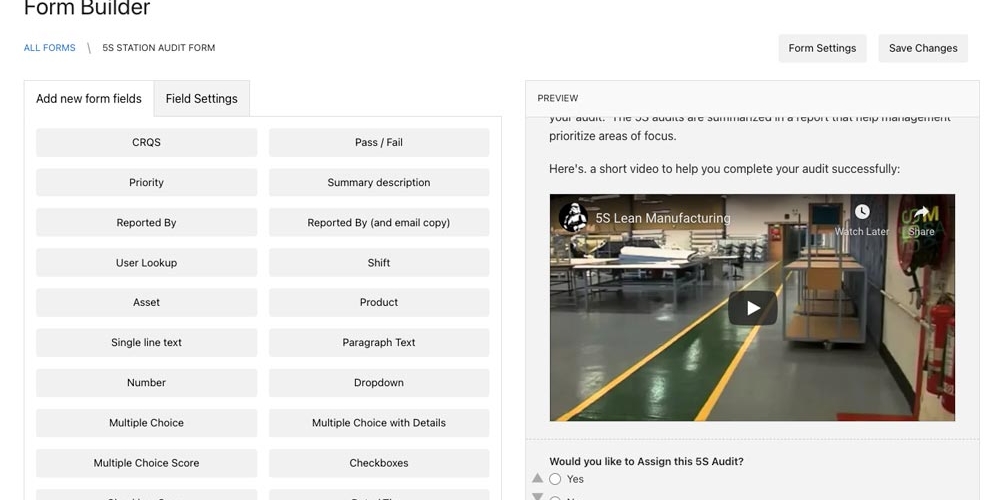

Key Features

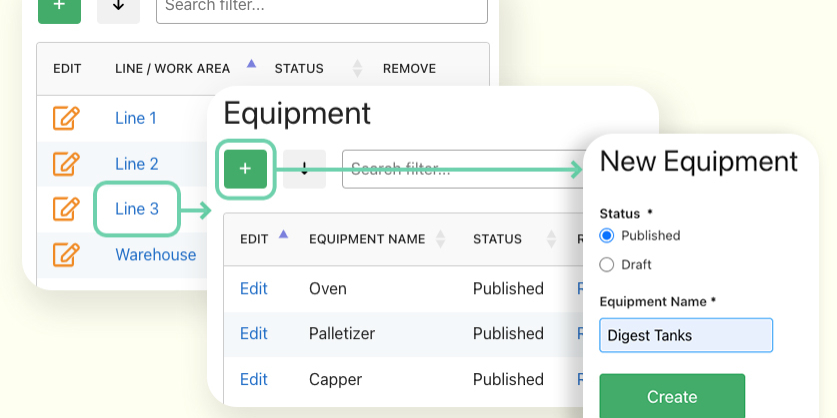

Create and manage schedules associated with lines, machines, shifts and staff members.

Automatically generate workflow tickets for evaluation and action when inspections fail.

Create and manage lists of common elements at your facility to standardize reports.

EXPLORE WEEVER inspections in action

Weever is universally useful for all your operations management requirements.

- All Solutions

- Compliance

- Continuous Improvement

- Maintenance

- Quality

- Safety

- Total Productive Maintenance

- Skills Development

- Warehouse

Safety Audits & Inspections

Ensure efficient and compliant completion of safety audit and inspection requirements.

Production Line Cleaning & Sanitation Checklist

Set up your sanitation schedule your way and refine it as you go.

100K+

Global Users

MILLIONS

of jobs completed

11

Languages

"The Weever suite is easy to understand and the support from the team has been amazing!"

Laura Curtis - Operational System and Process Manager, HelloFresh

"Weever saves me time, makes data visible and drives results!"

DENAIR M. - Training Manager

"Weever has changed how I run our business."

Ingrid K. - Plant Director

"Weever is extremely easy to use and simple to manage."

NICKI V - CI Engineer

"Weever gives me immediate insights into my business."

COLIN H. - Operational Excellence Manager

"The Weever team are extremely helpful and are always on hand to help with any questions or queries we may have."

Mel Cadle - Op Ex Lead Process Engineer, HelloFresh