Conditional Number Fields – Use Cases & Best Practices

The Weever platform includes conditional number functionality. This allows administrators to reveal certain form fields only if a response to a number field is above, below or in between a given threshold.

This article reviews some applicable use cases and best practices for how to set this up in your forms.

Use Cases

There are many instances in manufacturing where a number represents an issue that requires attention. Here are a few obvious examples.

Autonomous Maintenance Inspections

Autonomous Maintenance, a focus for many of our customers, requires machine operators to take on simple maintenance tasks (like cleaning, inspecting and lubricating components). This frees up time for the maintenance team, allowing them to focus on predictive and/or preventive measures.

With conditional numbers, it is possible to provide additional required inputs if an inspection is out of tolerance.

Elements that might be out of tolerance and case damage to machines or product quality issues include:

- Heat - A machine or component is running too hot for a prolonged period of time

- Pressure - A machine or component is running at a too high or too low pressure

- Moisture - A machine or component has a moisture reading that is too high

- Gaps - In-feed gap sizes for machines like conveyors could be too large or too small

Quality Defect Count

If you collect samples off the line for defect counts, you can use the conditional number approach to automatically require details and alert the quality manager if the count is above some acceptable level.

COVID Temperature Tests

When staff enter a facility, it is common practice nowadays to ask them to complete a COVID screening form, which may ask for their current temperature. If the temperature they record is over a tolerance (i.e. 100 ℉ for example), you can use conditional logic to request additional information and provide instructions.

The Cycle of Operational Excellence

Reporting an issue is the beginning of a Cycle of Operational Excellence that allows manufacturers to correct issues and prevent them from happening again. It is imperative that front line staff are enabled, energized and empowered to easily recognize and report issues.

Conditional logic is a great way to ensure operators can report issues with rich data quickly, which accellerates the next steps in the Cycle of Operational Excellence.

- Product or machine is out-of-tolerance. Supervisor is notified of the issue in real-time.

- Staff is rewarded for reporting the abnormality.

- Supervisor review submission and manages a project to ensure the problem does not recur.

- Project confirms root cause and requires a change to a procedure. SOP is updated and staff are trained.

- Reports show a quality defect on Line 1 Filler at 2:30PM as well as details about the project including ROI and other KPIs.

Best Practices

If a number is out-of-tolerance, usually the operator will either want to report that it was a temporary issue and was corrected immediately or that maintenance is required. If it was corrected immediately, your maintenance teams will still want to capture the data. If maintenance is required, you will want to alert the maintenance team and initiate a project.

Some tips for setting up the form include:

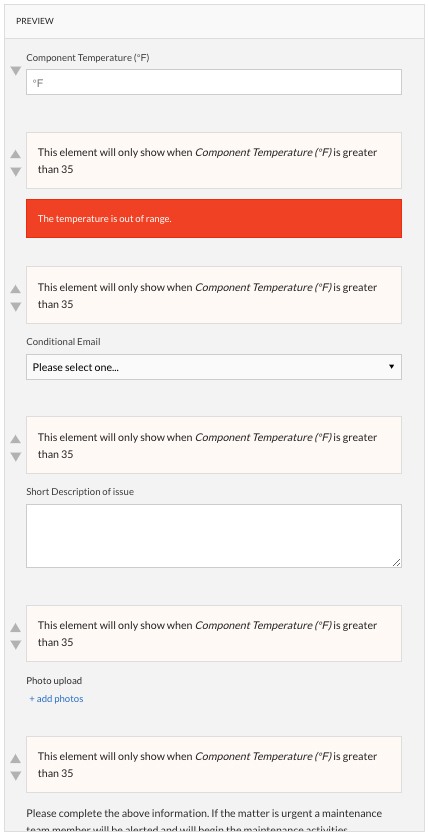

- Add a Number field requesting the heat, pressure, moisture information

- Add a Callout Box field alerting “The X is out of range.” conditional upon the Number field being greater than X tolerance.

- Add a Conditional Email field that provides the next step option for the operator, either immediate corrective action or maintenance required. If the operator selects “maintenance required”, set up the system to email your maintenance team. Note: you can ask your email administrator to set up an “alias” for your maintenance team that will email multiple people. Make this field conditional upon the Number field being greater than X tolerance.

- Add Paragraph and Photo Upload fields to capture data on the abnormality. Make these fields conditional upon the Number field being greater than X tolerance.

- You can use the form to capture data about what maintenance activities occurred. We like to add an Infobox that makes it clear to the operator that they have completed their part of the process followed by a Multiple Choice field that asks the maintenance team to begin their process. This field is helpful for reporting as well because you can generate reports on how many CIL abnormalities requested maintenance vs how many required maintenance.

- Add whatever field you would like to collect for maintenance activities. This example includes Date/Time fields for when the activities were started and were completed, a Paragraph field and a Photo field to document the activities.

- You could also add an Equipment field to document what resources the maintenance team used to document the process.

For more information on how to add conditional numbers to your forms, check out this knowledge base article.

Form Builder

Form with Conditional Logic

Weever is Operational Excellence Software that empowers the pursuit of perfection by enhancing operational visibility, collaboration and productivity in quality, maintenance, safety and production.

To learn more about how Weever can help you attain results in OpEx, please feel free to get in touch.