How Baywater Pipeline is Transforming Safety Reporting with Weever's Digital Solution

Expert in pipeline and facility construction, integrity, and maintenance services digitizes safety observations for better engagement and insights

weever case studies

case study highlights

- Increased monthly safety observation submissions by 230% from an average of 30-50 to 165 after implementing Weever's digital solution

- Achieved 92% completion rate on following up and addressing action items from safety observations, providing visibility previously lacking

- Boosted employee engagement through easy form access via QR codes and recognition awards for top submitters

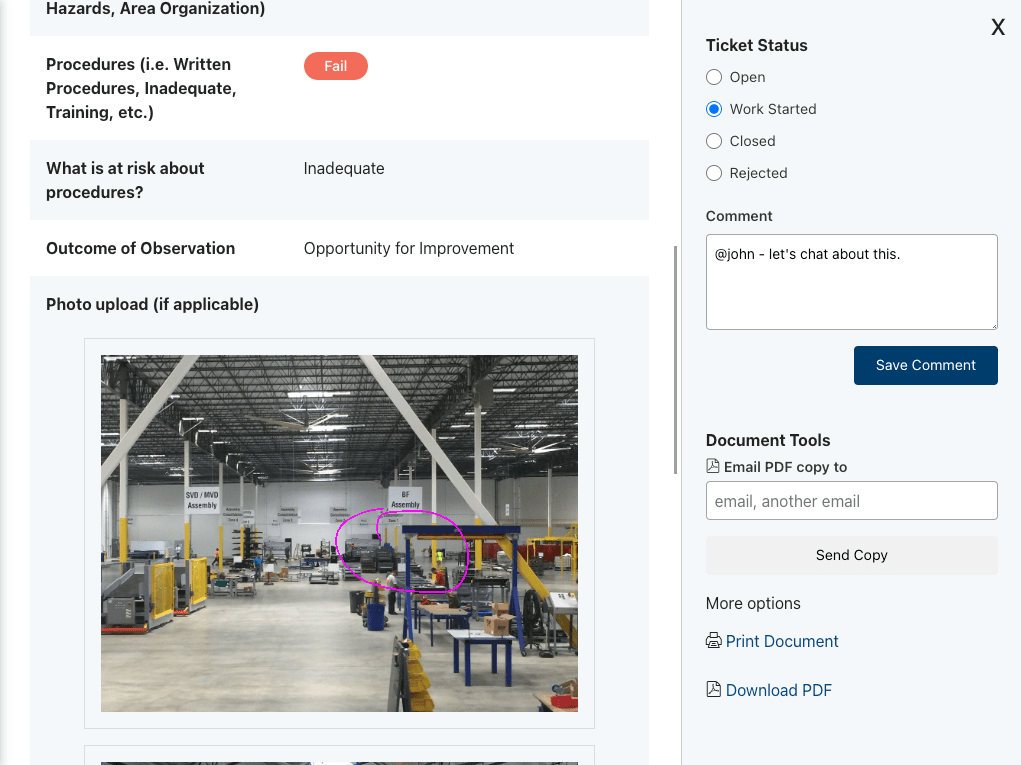

- Enabled real-time metric tracking and data analysis of safety trends across locations to identify areas for improvement

The Challenge

Ryne is the director of HR and Safety Compliance at a Baywater Pipeline, a prominent full-service contracting company in the energy sector. He was frustrated after encountering significant challenges in creating a sustainable safety observation program for several reasons.

- Paper forms and Excel sheets were not providing real-time metrics on these observations.

- He had disengaged staff, low participation results.

- Gaps in following up on action items.

- Forms were being misplaced and spreadsheets not being updated with the latest results.

A benchmark of 100 submissions per month was their initial goal, however, the program struggled to average between 30-50. Recognizing that this method was too cumbersome and time-consuming for his staff to maintain, the need for a digital solution was imperative.

The Implementation

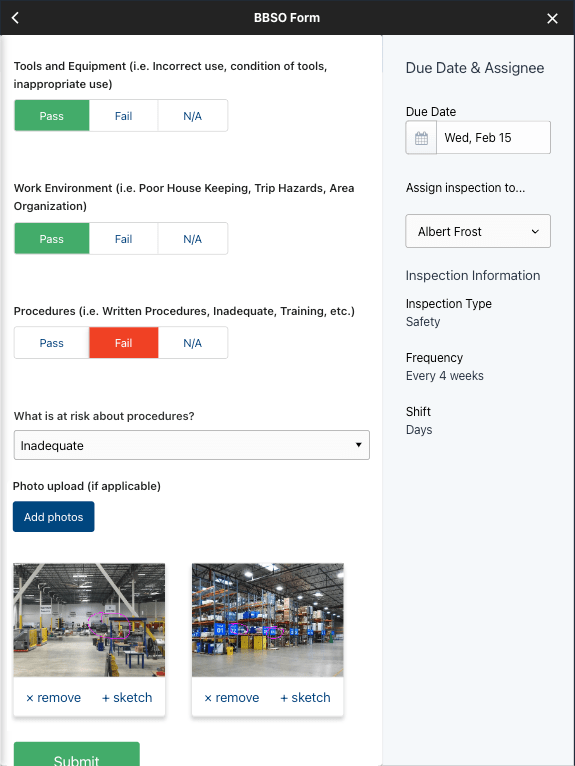

Working alongside Weever’s Customer Success team, Ryne was able to digitize his current paper form. This allowed every employee to have access to it anytime, without worry of misplacing it or forgetting to hand it in. Ryne immediately saw the value of having an online Form and went from losing submissions in transition from field to office, to now having no issues from staff at all.

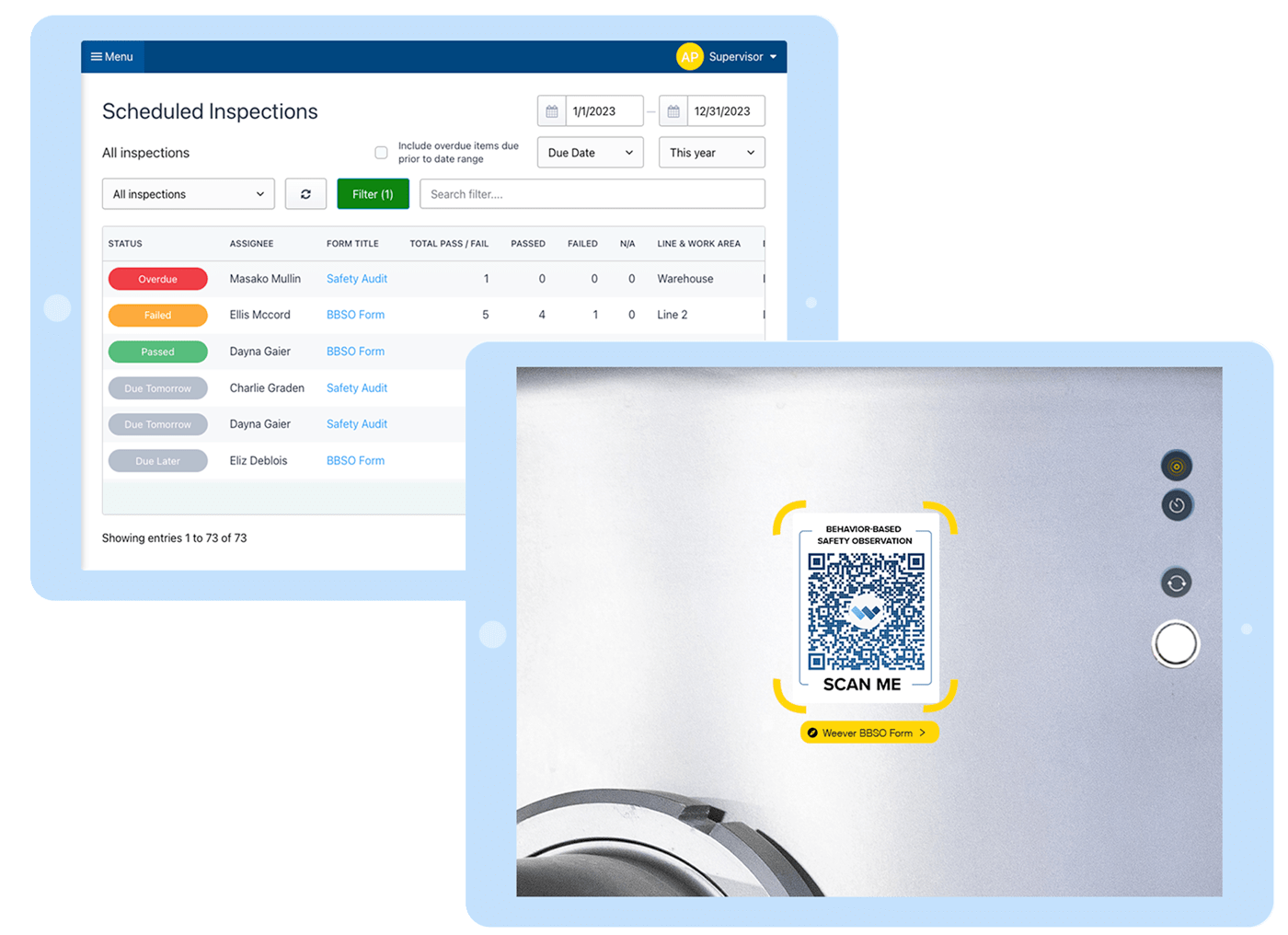

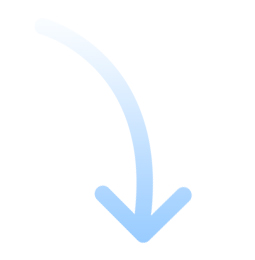

Ryne was also excited to see that he no longer had to manually input observation data into a spreadsheet, and could view the digital log of each submission whenever he needed to. Most importantly though, this digital log gave him greater control of following up on action items that need to be addressed and closed out when completed.

Engagement was tackled by creating QR code stickers to link staff directly to the form, and posters were displayed to encourage participation within common areas. The team now proudly presents recognition awards bestowed to the highest submitters each month and displays their recognition live on their LinkedIn page. The website and observation form were able to be displayed in Spanish, which was very important to Ryne having an about 40% Spanish speaking workforce. He stated “The digital aspect and easy-to-use software is a main selling point to our employees. Everyone is satisfied and happy overall.”

Gathering real-time metrics became a breeze after creating their safety report. The safety team can now view data from any given time period to track specific at-risk trends, see where improvements can be made and track site engagement and participation for each of their locations, all in one place.

The Results

- Increased Submissions: Monthly submissions soared to an average of 165, marking a 230% increase.

- Enhanced Engagement: Easy for staff to complete an observation in Weever due to the simple forms with complex automated workflows in the backend allowing safety managers to identify and correct issues immediately.

- Employee Recognition: The team can now recognize top performing staff to incentivize participation.

- Improved Data Management and Analysis: Better tracking and analysis of each location's safety trends and areas of improvement. Something previously hindered by the loss and mismanagement of paper records.

- High Completion Rates: The company has achieved a 92% completion rate on following up and addressing action items for safety observations, which is a metric they never had insight into before.

- Support from Upper Management: The initiative received strong backing from the company's President, providing a tangible tool to promote safety and operational excellence.

Looking Ahead

Encouraged by the success of the safety observation program, Ryne is looking to drive submission numbers to 500 per month across all sites. The company as whole is also exploring additional use cases to further enhance their digital operations.

Conclusion

The transition to Weever's digital solution represents a significant step forward in the company's pursuit of operational excellence and safety. By embracing digital transformation, they have not only improved engagement and efficiency but have also laid the groundwork for continuous improvement in their operations.

Interested in creating a sustainable safety observation program?

Behavior-Based Safety Observations

Everything you need to get it done.

Customizable Templates

Dashboard Reporting

Automated Workflows

Schedule Management

Real-time Visibility

On-Demand Instructions

bandjlogo

Bell-logo-New

Canadian-Tire-Logo

Diageo-customer-logo

greyston-bakery-logo

hello-fresh-customer

marks-customer-logo

CSL_Limited_logo

monin-logo

Winland Food

Mars-logo-main

rise-baking-customer-logo

Rockwool-Customer-Logo-min

Sportcheck-customer-logo

unilever-customer-logo

walmart-logo-small

husqvarna-customer-logo

Ajinomoto_logo

Peet's_Coffee_logo

Royal-Canin-Logo

Digital DATA CAPTURE

Get it done correctly every time.

WORKFLOW AUTOMATION

Evaluate and improve.

REAL-TIME REPORTING

Automate Business Intelligence.

100K+

Global Users

MILLIONS

of jobs completed

11

Languages

"The Weever suite is easy to understand and the support from the team has been amazing!"

Laura Curtis - Operational System and Process Manager, HelloFresh

"Weever saves me time, makes data visible and drives results!"

DENAIR M. - Training Manager

"Weever has changed how I run our business."

Ingrid K. - Plant Director

"Weever is extremely easy to use and simple to manage."

NICKI V - CI Engineer

"Weever gives me immediate insights into my business."

COLIN H. - Operational Excellence Manager

"The Weever team are extremely helpful and are always on hand to help with any questions or queries we may have."

Mel Cadle - Op Ex Lead Process Engineer, HelloFresh