Welcome to the Digitization Mavericks Blog.

Digitization Mavericks is dedicated to helping manufacturing leaders drive efficiency, quality, and safety through digital transformation.

Topics covered include 5S Auditing, Operational Excellence, proactive safety, quality management, and sanitation. The articles provide actionable insights and best practices to help you get the most out of your factory floor.

Search our blog

- All Articles

- 5S Auditing

- AM

- Behavior Based Safety Observations

- Best Practices

- Digitization Mavericks

- Digitization Mavericks Podcast

- Employee Engagement

- Maintenance Management

- Operational Excellence

- Proactive Safety

- Production Management

- Quality Management

- Safety Management

- Sanitation Management

- Webinars

How to increase Employee Engagement by focusing on Ease and Usefulness

According to numerous studies Continuous Improvement program participation can be predicted by the amount of intention employees have to participate, which is inflences by Ease and Usefulness of participation.

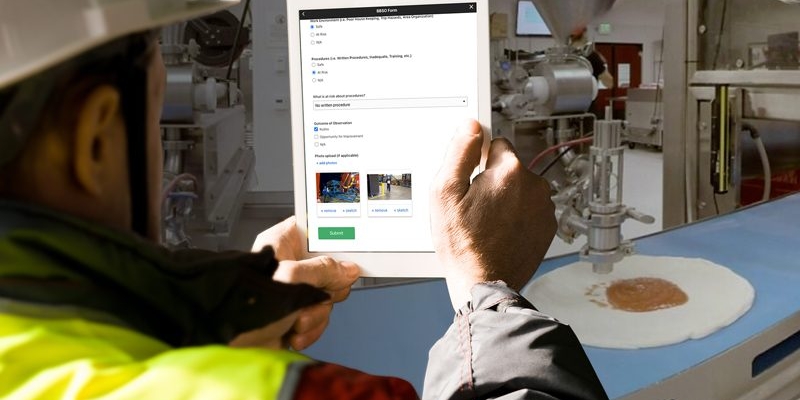

How to Perform Health and Safety Observations

Implement effective health and safety observations to boost workplace safety and compliance with practical tips and proven strategies.

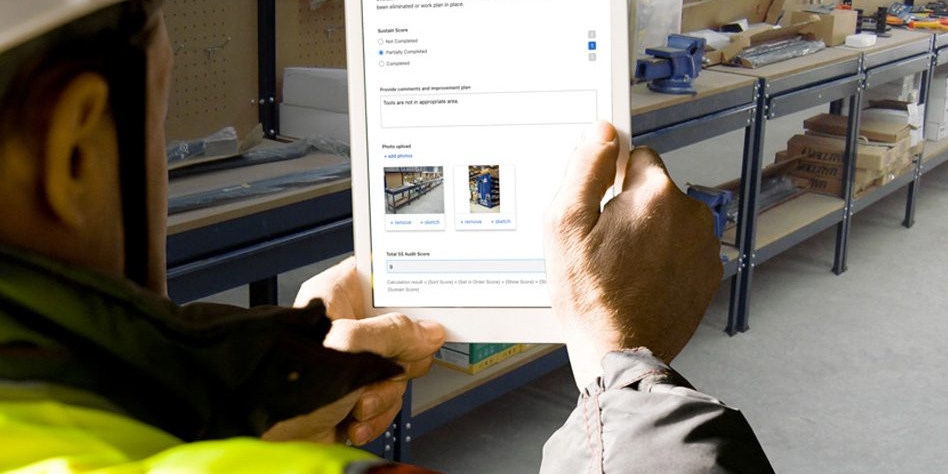

How to Perform Workplace Audits and Inspections

Master workplace audits and inspections with tips, tools, and strategies for a safer, compliant work environment. Discover key actions and best practices.

How to protect essential workers in the factory.

Over 20 tips on how to keep factory workers safe and productive during a global…

How to remove wasted administration time from your audits

How to remove wasted administration time from your auditing process Andy Pritchard | March 23,…

How to simplify inspection schedules

Your front line staff are busy and your inspections are important. Simplification goes a long way to ensuring inspections get done on-time and correctly.

How to stimulate positive change in your manufacturing facility during a pandemic.

3 tips for enhancing continuous improvement during COVID-19 and beyond. COVID-19 is a global pandemic…

How to Train Frontline Staff on 5S

How to Train Frontline Staff on the Essentials of 5S Principles Best practices for efficiently…

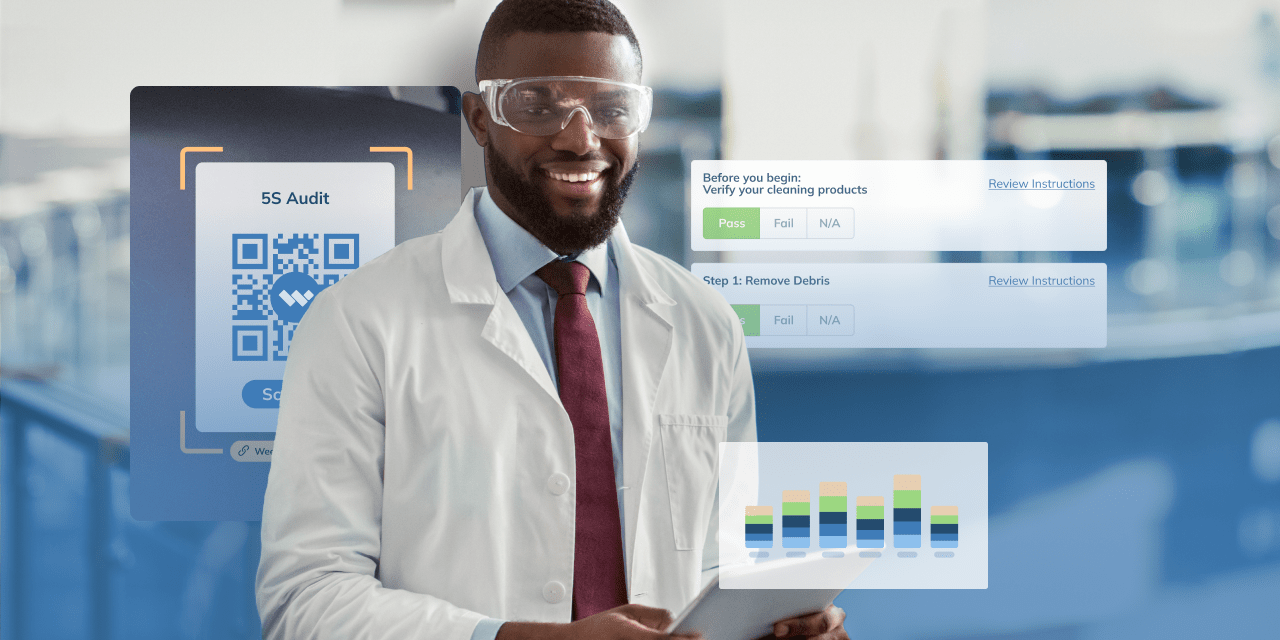

How to Use a 5S Audit Scorecard in Manufacturing to Drive Staff Participation

Proactive safety is about preventing incidents before they occur. What are some simple and practical steps you can take to be more proactive now?

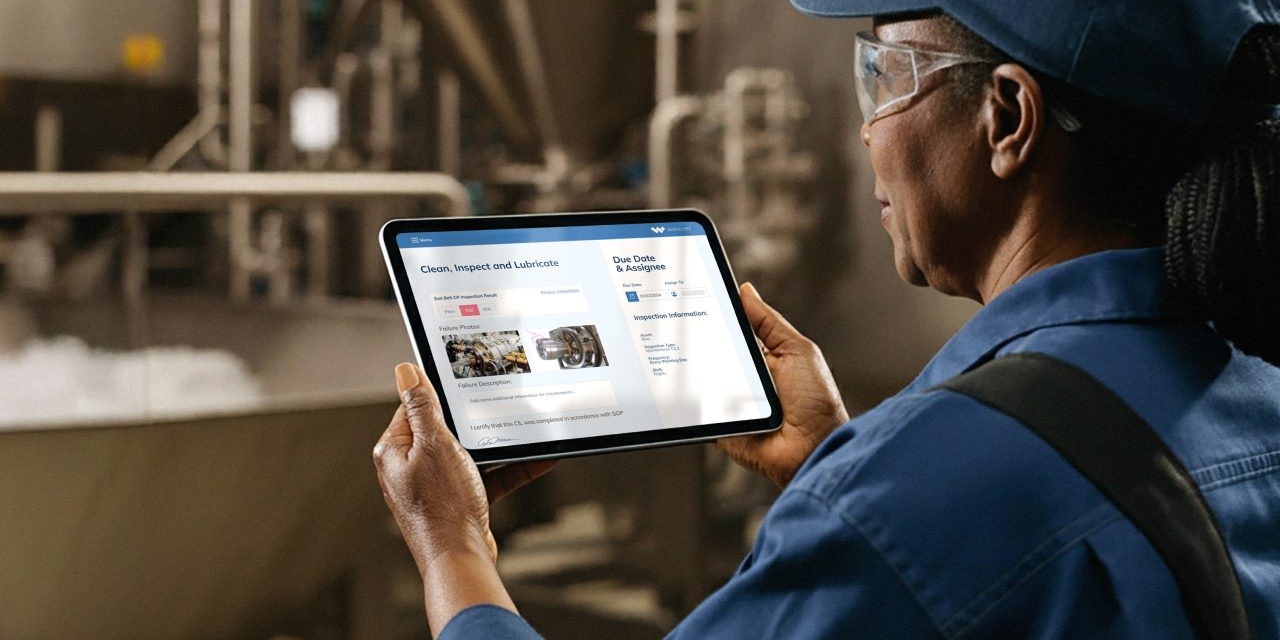

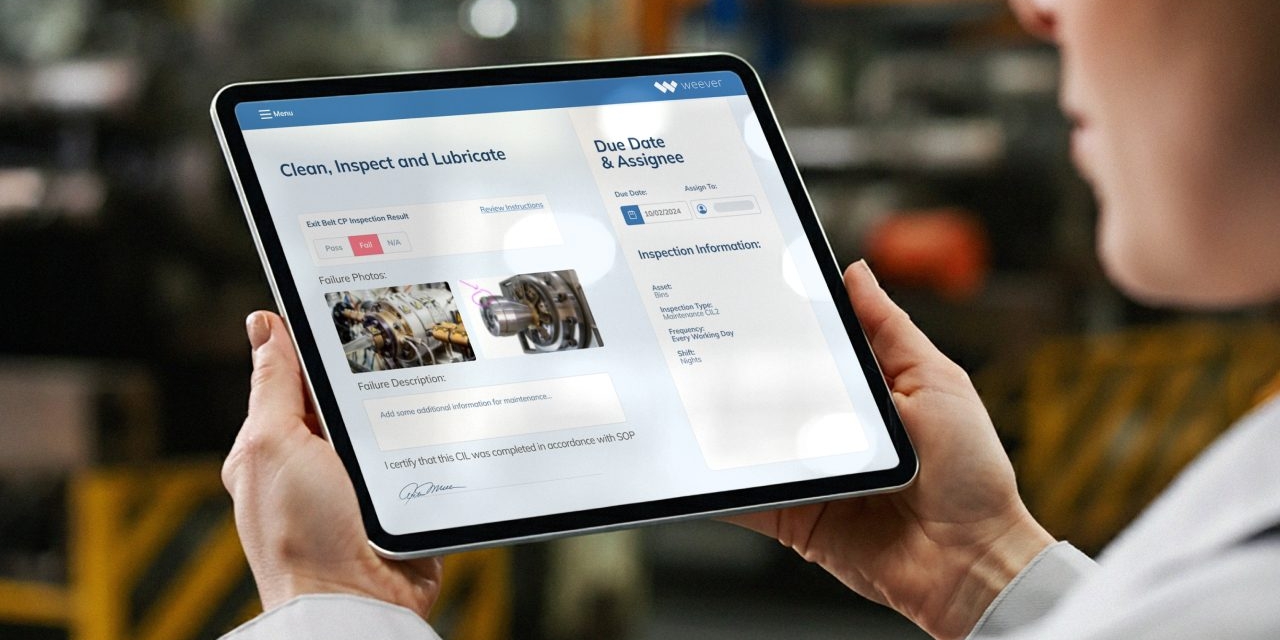

How Weever Automates CIL Tasks to Streamline Maintenance Efficiency

How Weever Automates CIL Tasks to Streamline Maintenance Efficiency Discover how Weever’s visual controls simplify…

How Weever Revolutionizes Food Manufacturing Operations?

How Weever Revolutionizes Food Manufacturing Operations? Discover the top connected worker platforms for food manufacturing…

How Weever Simplifies Abnormality Detection and Resolution for Manufacturers

How Weever Simplifies Abnormality Detection and Resolution for Manufacturers Optimize manufacturing efficiency with Weever’s digital…

How Weever Supports Continuous Improvement through CIL and 5S Audits

Proactive safety is about preventing incidents before they occur. What are some simple and practical steps you can take to be more proactive now?

Implementing 7S Workplace Organization Techniques

Implement 7S Workplace Organization techniques to boost productivity, enhance efficiency, and create a streamlined workspace.

Implementing Safety Observations at Work: Best Practices

Boost workplace safety with effective safety observations at work. Learn best practices for implementing and maintaining safety standards.

Implementing Step 2 of Autonomous Maintenance

Implement autonomous maintenance step 2 to boost productivity and safety. Gain practical insights and learn from real-world examples.

Improving Safety with Behavioral Observations

Enhance safety with behavioral safety observations. Learn practical tips and stats to boost workplace safety efficiently.

Inspiring Autonomous Maintenance Slogans for Your Team

Unleash creativity with inspiring autonomous maintenance slogans that boost team spirit and productivity in your maintenance operations.

Is 5S right for you?

If you are uncertain whether 5S is right for your facility askyourself and your team the following questions.If the answer was “yes” to one or more of these questionsyou may find 5S to be very beneficial to your organization.

Is Workplace Safety Everyone’s Responsibility?

Explore if workplace safety is everyone’s responsibility and how to foster a culture of safety in your organization effectively.

Jishu Hozen: Mastering Autonomous Maintenance

Explore Jishu Hozen’s role in mastering autonomous maintenance. Boost operational efficiency with proactive strategies and empower your maintenance team.

Jishu Hozen: Mastering Autonomous Maintenance

Learn Jishu Hozen autonomous maintenance to boost productivity. Explore strategies, tools, and tips for mastering equipment care and improvement.

Kamishibai Lean: A Practical Guide

Learn how Kamishibai boards enhance lean manufacturing with visual management, improve efficiency, and support continuous improvement in your processes.

Key Elements of Autonomous Maintenance Presentations

Explore key elements of autonomous maintenance PPT free download and enhance your maintenance strategies with effective presentation tips.

Key Leadership Trends in Today’s Mobile Forms Market

Mobile forms solutions have proven to be a popular way to ease today’s businesses into…

Key Steps for Successful Autonomous Maintenance

Master each step in autonomous maintenance to boost efficiency and reduce downtime in your operations with expert guidance and practical examples.

Leveraging 5S Audit Scorecards for Continuous Improvement

Proactive safety is about preventing incidents before they occur. What are some simple and practical steps you can take to be more proactive now?

Leveraging Your 5S Audit Scorecard for Continuous Improvement in Manufacturing with Weever

Proactive safety is about preventing incidents before they occur. What are some simple and practical steps you can take to be more proactive now?

Mark’s, Canadian Tire, SportChek solves vendor non-compliance with Weever.

We needed a way to document non compliant shipments sent to us from our vendors in a way the clearly demonstrated the errors to the vendors. Additionally, we needed to capture this evidence from multiple locations with distribution to specific downstream teams (including the ability to have a file format that can be saved on an SFTP0 based on the location that identified the non compliance.

Martin SC saves over $70K per year with Weever

Weever specializes in digitizing operational workflows. We work with organizations of all shapes and sizes who are frustrated with paper forms and spreadsheets. They want to save money, become more efficient, and spend their time more wisely.

Mastering Autonomous Maintenance: A Seven-Step Guide

Master autonomous maintenance in seven steps to boost efficiency, reduce downtime, and enhance productivity with our expert tips and strategies.

Mastering Autonomous Maintenance: PPT Guide

Master autonomous maintenance with our PPT guide. Enhance uptime, cut costs, and streamline operations with proven strategies and insights.

Mastering the Seven Steps of Autonomous Maintenance

Learn the autonomous maintenance 7 steps to enhance efficiency, reduce downtime, and boost productivity in your manufacturing process.

Maximizing Productivity in Food Warehouses with Autonomous Maintenance: How Weever Makes It Possible

Maximizing Productivity in Food Warehouses with Autonomous Maintenance: How Weever Makes It Possible Maximize productivity…

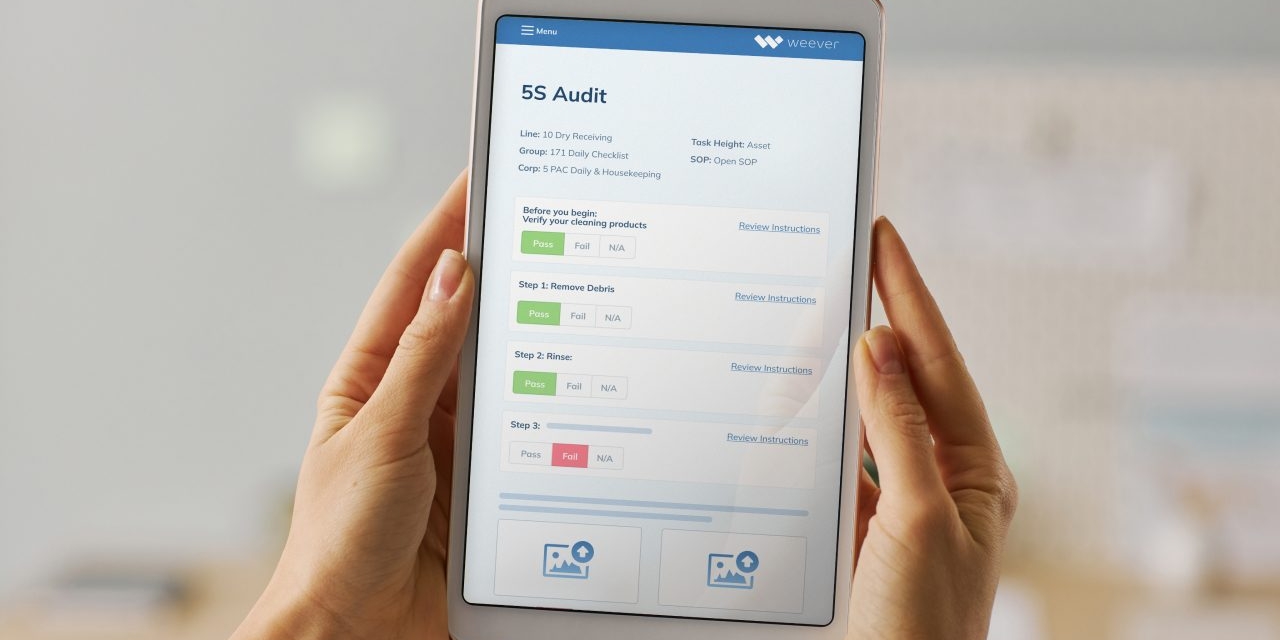

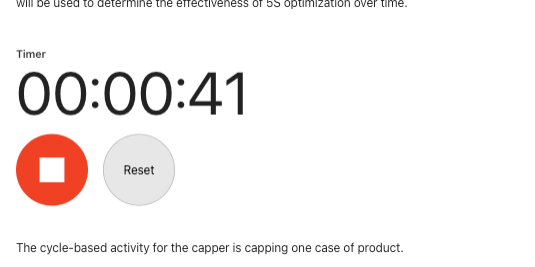

Measure the Real Impact of your 5S Audits with Cycle-based Activity Timing

Cycle time is the duration of one production cycle, and it can be used as a metric to identify improvement opportunities in a manufacturing process. By measuring cycle time, managers can identify bottlenecks, waste, and inefficiencies, and develop strategies to improve the process.

Monin saves 3-4 hours each day with Weever

Monin was drowning in paper and looking for a system that would ensure compliant workflows and automate KPI reporting insights to inform continuous process improvement, all without overwhelming operators.

Operator-Led CIL Training with Weever: Bridging Knowledge Gaps Across Different Manufacturing Industries

Operator-Led CIL Training with Weever: Bridging Knowledge Gaps Across Different Manufacturing Industries Discover how Weever…

Optimizing Lubrication Schedules with Weever: Improving Machine Longevity

Optimizing Lubrication Schedules with Weever: Improving Machine Longevity Optimize lubrication schedules, enhance machine longevity, and…

Optimizing Workplace Safety and Efficiency with Weever’s 5S Audits

Proactive safety is about preventing incidents before they occur. What are some simple and practical steps you can take to be more proactive now?

Optimizing Your Manufacturing 5S Audit Process with Weever’s Digital Tools

Proactive safety is about preventing incidents before they occur. What are some simple and practical steps you can take to be more proactive now?